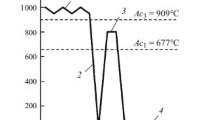

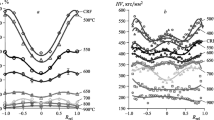

The effect of cold radial forging of steel 10Kh3G3MFS in a two-phase martensitic-ferritic state on the kinetics of formation of austenite under subsequent heating at different rates is studied. The quantitative characteristics of the stages of formation of the austenite are determined and a thermokinetic diagram of the austenitization is plotted. The parameters of the martensitic-ferritic structure and of the hardness of the steel are shown to depend on the temperature of quenching from the intercritical temperature range. The influence of preliminary radial forging on the behavior of the curves of uniaxial tension of the steel after incomplete quenching is studied and compared to the results obtained earlier for a quenched condition.

Similar content being viewed by others

References

Yu. N. Simonov,M. Yu. Simonov, D. N. Poduzov, et al., “Transformations, structure and properties of system-alloyed low-carbon nickel-free steels,” Metalloved. Term. Obrab. Met., No. 11(689), 4 – 11 (2012).

L. M. Kleiner, D. M. Larinin, L. V. Spivak, and A. A. Shatsov, “Phase and structural transformations in low-carbon martensitic steels,” Fiz. Met. Metalloved., 108(2), 161 – 168 (2009).

D. O. Panov and A. I. Smirnov, “Special features of formation of austenite in low-carbon steel under heating in the intercritical range,” Fiz. Met. Metalloved., 118(11), 1138 – 1148 (2017).

L. Ts. Zayats, D. O. Panov, Yu. N. Simonov, et al., “Special features of processes of formation of austenite in the intercritical temperature range in initially quenched low-carbon steels with different alloying systems,” Fiz. Met. Metalloved., 112(5), 505 – 513 (2011).

D. O. Panov, Yu. N. Simonov, P. A. Leont’ev, et al., “A study of phase and structural transformations of quenched low-carbon steel under the conditions of multiple intense thermal impact,” Metalloved. Term. Obrab. Met., No. 11(689), 28 – 32 (2012).

D. O. Panov, A. N. Balakhnin, M. G. Titova, et al., “Evolution of the structure and properties under intense thermocycling treatment of cold-deformed quenched system-alloyed steel 10Kh3G3MF,” Metalloved. Term. Obrab. Met., No. 11(689), 17 – 22 (2012).

A. S. Ermolaeva, M. G. Zakirova, L. M. Kleiner, and Yu. N. Simonov, “Structure and properties of low-carbon martensitic steels quenched from the intercritical temperature range,” Konstr. Komp. Mater., No. 4, 172 – 177 (2006).

Yu. N. Simonov, M. Yu. Simonov, D. O. Panov, et al., “Formation of structure of lower carbide-free bainite due to isothermal treatment of steels of type Kh3G3MFS and KhN3MFS,” Met. Sci. Heat Treat., 58(1 – 2), 61 – 79 (2016). DOI: https://doi.org/10.1007/s11041-016-9965-z

D. O. Panov, T. Yu. Barsukova, A. I. Smirnov, et al., “Intercritical quenching of low-carbon steels with formation of a fine multiphase structure,” Obrab. Met. (Tekhnol., Oborud., Instr.), No. 4(77), 6 – 18 (2017). https://doi.org/10.17212/1994-6309-2017-4-6-18

T. Yu. Barsukova, D. O. Panov, and Yu. N. Simonov, “Laws of formation of structure and properties in cold-deformed low-carbon structural steel under incomplete quenching,” Metalloved. Term. Obrab. Met., No. 7, 3 – 9 (2021).

T. Yu. Barsukova, D. O. Panov, A. S. Pertsev, et al., “Evolution of the structure and properties of multiphase low-carbon steel during cold radial forging,” Metalloved. Term. Obrab. Met., No. 10(772), 25 – 32 (2019).

L. I. Gladshtein, T. N. Rivanenok, and A. V. Khristov, “Dilatometric analysis of the kinetics of polymorphic transformation under heating,” Zavod. Lab., Diagn. Met., 74(6), 36 – 39 (2008).

T. Yu. Barsukova, D. O. Panov, and M. Yu. Simonov, “Formation of superfine-grained ferritic-martensitic structure in low-carbon structural steel in quenching from intercritical temperature range,” Tekhnol. Met., No. 11, 2 – 12 (2019).

S. K. Greben’kov, A. A. Shatsov, D.M. Larinin, and L. M. Kleiner, “Deformation hardening of low-carbon martensitic steels,” Metalloved. Term. Obrab. Met., No. 2, 33 – 38 (2016).

S. K. Greben’kov, V. A. Skudnov, and A. A. Shatsov, “Deformation and fracture of low-carbon martensitic steels,” Metalloved. Term. Obrab. Met., No. 2, 33 – 38 (2016).

A. Chbihi, D. Barbier, L. Germain, et al., “Interactions between ferritic recrystallization and austenite formation in high-strength steels,” J. Mater. Sci., 49(10), 3608 – 3621 (2014). https://doi.org/10.1007/s10853-014-8029-2

D. O. Panov, Yu. N. Simonov, L. V. Spivak, and A. I. Smirnov, “Stages of austenitization of cold-deformed low-carbon steel in intercritical temperature range,” Fiz. Met. Metalloved., 116(8), 846 – 853 (2015).

M. Tokizane, N. Matsumura, K. Tsuzaki, et al., “Recrystallization and formation of austenite in deformed lath martensitic structure of low carbon steels,” Metall. Trans. A, 13, 1379 – 1388 (1982). DOI: 10.1007/BF02642875

J. Huang, W. J. Poole, and M. Millitzer, “Austenite formation during intercritical annealing,” Metall. Mater. Trans., 35(11), 3363 – 3375 (2004).

E. Tesser, C. Silva, A. Artigas, and A. Monsalve, “Effect of carbon content and intercritical annealing on microstructure and mechanical tensile properties in FeCMnSiCr TRIP-assisted steels,” Metals, 11(10) (2021). https://doi.org/10.3390/met11101546

M. A. Gervas’ev, A. S. Yurovskikh, S. V. Belikov, et al., “Effect of Al and Si on formation of austenite in intercritical temperature range of Cr – Ni – Mo-steel,” Chern. Metall., 58(9), 677 – 681 (2015).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 4, pp. 13 – 20, April, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Barsukova, T.Y., Panov, D.O., Simonov, Y.N. et al. Special Features of the α → γ Transformation of Radially Forged Low-Carbon Steel in the Intercritical Temperature Range. Met Sci Heat Treat 65, 200–208 (2023). https://doi.org/10.1007/s11041-023-00915-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-023-00915-0