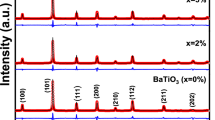

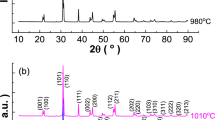

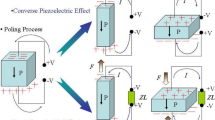

Ceramic materials of the Bi0.5Na0.5TiO3– xZnO (BNT – xZnO) system with the content of ZnO x = 0 and 2.0 wt.% obtained by the classical solid-state reaction method are studied. The initial powders (Bi2O3, TiO2 and Na2CO3) with a ZnO addition are milled for 10 h, calcined at 850°C for 3 h, pressed, and sintered at 1050°C for 3 h. The morphology and the microstructure of the sintered granules are studied using XRD, scanning electron microscopy, and a helium pycnometer. It is shown that the material acquires a solid solution of (Bi0.5Na0.5)TiO3 with a structure of pure perovskite and Zn2TiO4 spinel. The piezoelectric coefficient d33 after the sintering at 1050°C for the BNT ceramics amounts to 155 pC/N; in the case of BNT with 2 wt.% ZnO the value is 181 pC/N. The ZnO addition to the BNT ceramics raises the density of the material and provides an electrical conductivity of 7.48 × 108 Ω∙ cm.

Similar content being viewed by others

References

Kenji Shibata, Ruiping Wang, Tonshaku Tou, and Jurij Koruza, “Applications of lead-free piezoelectric materials,” Mater. Res. Soc., 43, 612 – 616 (2018); https://doi.org/10.1557/mrs.2018.180.

Jigong Hao, Wei Li, Jiwei Zhai, and Haydn Chen, “Progress in high-strain perovskite piezoelectric ceramics,” Mater. Sci. Eng. R, 135, 1 – 57 (2018); https://doi.org/10.1016/j.mser.2018.08.001.

A. N. Rybyanets, D. I. Makarev, and N. A. Shvetsova, “Recent advances in porous piezoceramics applications,” Ferroelectrics, 539, 106 – 116 (2019); https://doi.org/10.1080/00150193.2019.1570019.

G. H. Haertling,“ Ferroelectric ceramics: History and technology,” J. Am. Ceram. Soc., 82, 797 – 818 (1999); https://doi.org/10.1111/j.1151-2916.1999.tb01840.x.

C. R. Bowen, H. A. Kim, P. M. Weaver, and S. Dunn, “Piezoelectric and ferroelectric materials and structures for energy harvesting applications,” Energy Environ. Sci., 7(1), 25 – 44 (2014); doi: https://doi.org/10.1039/C3EE42454E.

J. Röedel, K. G. Webber, R. Dittmer, et al., “Transferring lead free-piezoelectric ceramics into applications,” J. Eur. Ceram. Soc., 35(6), 1659 – 1681 (2015); https://doi.org/10.1016/j.jeurceramsoc.2014.12.013.

A. Priya, “Advances in energy harvesting using low profile piezoelectric transducers,” J. Electroceram., 19, 165 – 182 (2007); https://doi.org/10.1007/s10832-007-9043-4.

Wenfeng Liu, Lu Cheng and Shengtao Li, “Prospective of (BaCa)(ZrTi)O3 lead-free piezoelectric ceramics,” Crystals, 9(3), 179 (2019); https://doi.org/10.3390/cryst9030179.

AshutoshUpadhyay, Hyun Ae Cha, and Jae-Ho Jeon, “Stabilities and piezoelectrics properties of amorphotropic phase boundary composition 0.2Pb(Mg1/3Nb2/3)O3– 0.38PbZrO3–0.42PbTiO3 ternary piezoelectrics”, J. Mater. Sci., 54(9), 6799 – 6806 (2019); https://doi.org/10.1007/s10853-019-03365-3.

Binal P. Bruno, Ahmed Raouf Fahmy, Moritz Stürmer, et al., “Properties of piezoceramic materials in high electric field actuator applications,” Smart Mater. and Struct., 28, 015029 (2019); https://doi.org/10.1088/1361-665X/aae8fb.

J. F. Scott, “Applications of modern ferroelectrics,” Science, 315, 954 – 959 (2007); doi: https://doi.org/10.1126/science.1129564.

B. Jaffe, R. S. Roth, and S. Marzullo, “Piezoelectric properties of lead zirconate-lead titanate solid solution ceramics,” J. Appl. Phys., 25, 809 – 810 (1954); https://doi.org/10.1063/1.1721741.

Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment (RoHS), Directive 2002/95/EC of the European Parliament and the Council (2003).

J. Rödel,W. Jo, K. T. P. Seifert, et al., “Perspective on the development of lead-free piezoceramics,” J. Am. Ceram. Soc., 92(6), 1153 – 1157 (2009); https://doi.org/10.1111/j.1551 – 2916.2009.03061.x.

Y. Saito, H. Taiko, T. Tani, et al., “Lead-free piezoceramics,” Nature, 432, 84 – 87 (2004); https://doi.org/10.1038/nature03028.

J. Walter and J. Merz, “The electric and optical behavior of BaTiO3 single-domian crystals,” Phys. Rev., 76(8), 1222 – 1225 (1949); https://doi.org/10.1103/PhysRev.76.1221.

W. P. Mason, “Electrostrictive effect in barium titanate ceramics,” Phys. Rev., 74(9), 1134 – 1147 (1948); https://doi.org/10.1103/PhysRev.74.1134.

Akça Erdem and Yılmaz Hüseyin, “Lead-free potassium sodium niobate piezoceramics for high-powerultrasonic cutting application: Modelling and prototyping,” Proc. Appl. Ceram., 13(1), 65 – 78 (2019); https://doi.org/10.2298/PAC1901065A.

R. E. Jaeger and L. Egerton, “Hot pressing of potassium-sodium niobates,” J. Am. Ceram. Soc., 45(5), 209 – 213 (1962); https://doi.org/10.1111/j.1151-2916.1962.tb11127.x.

L. Egerton and D. M. Dillon, “Piezoelectric and dielectric properties of ceramics in the system potassium-sodium niobate,” J. Am. Ceram. Soc., 42(9), 438 – 442 (1962); https://doi.org/10.1111/j.1151-2916.1959.tb12971.x.

Chenwan Li, Ling Yang, Jiwen Xu, et al., “The effect of artificial stress on structure, electrical and mechanical properties of Sr2+ doped BNT – BT lead-free piezoceramics,” J. Mater. Sci. Mater. Electron., 30(24), 21398 – 21405 (2019); https://doi.org/10.1007/s10854-019-02518-z.

Guanhua Song, Zhibin Liu, Faqiang Zhang et al, “High-throughput synthesis and electrical properties of BNT-BTKNN lead-free piezoelectric ceramics,” J. Mater. Chem. C, 8(11), 3655 – 3662 (2020); doi: https://doi.org/10.1039/c9tc06745k.

Zhi-Hao Zhao, Rui-Fang Gey, and Yejing Dai, “Large electro-strain signal of the BNT – BT – KNN lead-free piezoelectric ceramics with CuO doping,” J. Adv. Dielectr., 9(3), 1950022 (2019); https://doi.org/10.1142/S2010135X1950022X.

Carl F. Buhrer, “Some properties of bismuth perovskites,” J. Chem. Phys., 36(3), 798 – 803 (1962); https://doi.org/10.1063/1.1732613.

D. A. Benavides Fernandez, A. I. Gutierrez-Perez, A. M. Benitez-Castro, et al., “Comparative study of ferroelectric and piezoelectric properties of BNT – BKT – BT ceramics near the phase transition zone,” Materials, 11(3), 361 (2018); https://doi.org/10.3390/ma11030361.

Xiao-Yu Geng, Zhang Ji,Wang Rui-Xue, et al., “ZnO-enhanced electrical properties of Bi0.5Na0.5TiO3-based incipient ferroelectrics,” J. Am. Ceram. Soc., 100(12), 5659 – 5667 (2017); DOI: https://doi.org/10.1111/jace.15090.

Hsin-Ying Chiang, Ying-Chieh Lee and Teoh Lay Gaik, “Effect of microwave sintering on the microstructure and piezoelectric properties of ZnO-doped Bi0.5Na0.5TiO3 ceramics,” J. Ceram. Soc. Japan, 121(5), 430 – 436 (2013); https://doi.org/10.2109/jcersj2.121.430.

Zhi-Tao Li, Liu Hui, Hao-Cheng Thong, et al., “Enhanced temperature stability and defect mechanism of BNT-based lead-free piezoceramics investigated by a quenching process,” Adv. Electron. Mater., 1800756 (2018); https://doi.org/10.1002/aelm.201800756.

M. Supalak, T. Tawee, J. Pharatree, et al., “Electrical properties of modified BNT based lead-free ceramics,” Mater. Sci. Forum, 872, 87 – 91 (2016); https://doi.org/10.4028/www.scientific.net/MSF.872.87.

Yongli Wang, Longtu Li, Jianquan Qi, and Zhilun Gui, “Frequency response of ZnO-doped BaZrxTi1–xO3 ceramics,” Mater. Chem. Physics, 76(3), 250 – 254 (2002); https://doi.org/10.1016/S0254-0584(01)00534-X.

Chuen-Shi Chou, Chun-Yu Wu, Ru-Yuan Yang, and Cheng-Yang Ho, “Preparation and characterization of the bismuth sodium titanate (Na0.5Bi0.5TiO3) ceramic doped with ZnO,” Adv. Powder Technol., 23, 358 – 365 (2012); https://doi.org/10.1016/j.apt.2011.04.015.

D. C. Look, “Recent advances in ZnO materials and devices,” Mater. Sci. Eng. B, 80(1 – 3), 383 – 387 (2001); https://doi.org/10.1016/S0921-5107(00)00604-8.

Z. L. Wang, “Nanostructures of ZnO for nanoscale photonics, optoelectronic, piezoelectricity, and sensing,” Appl. Phys. A, 88(1), 7 – 15 (2007); https://doi.org/10.1007/s00339-007-3942-8.

R. Bovhyra, D. Popovych, O. Bovgyra, and A. Serednytski, “Ab initio study of structural and electronic properties of (ZnO)n “magical” nanoclusters n = (34, 60),” Nanoscale Res. Lett., 12(1), 76 (2017); https://doi.org/10.1186/s11671-017-1848-8.

X. Han, J. Harris, and L. Siller, “Synthesis of porous zinc-based/zinc oxide composites via sol-gel and ambient pressure drying routes,” J. Mater. Sci., 53(11), 8170 – 8179 (2018); https://doi.org/10.1007/s10853-018-2138-2.

L. P. Etcheverry, V. H. Flores, D. L. Silva, and A. C. Moreira, “Annealing effects on the structural and optical properties of ZnO nanostructures,” Mater. Res., 21(2), 1 – 7 (2018); https://doi.org/10.1590/1980-5373-mr-2017-0936.

L. Lutteroti, MAUD 2000, Version 2.50; http://maud.radiographema.

Alima Mebrek, Sihem Benayache, Afef Azzi, et al., “Structural properties of sintered zinc titanate ceramics,” AIP Conf. Proc., 2123(1), 030013 (2019); https://doi.org/10.1063/1.5117044.

Alima Mebrek, Safia Alleg, Sihem Benayache, and Mohamed Benabdeslem, “Preparation and characterization of spinel-type Zn2TiO4 nanocomposite,” Ceram. Int., 44(9), 10,921 – 109,28 (2018); https://doi.org/10.1016/j.ceramint.2018.03.153.

R. E. Newnham, D. P. Skinner, and L. E. Cross, “Connectivity and piezoelectric-pyroelectric composites,” Mater. Res. Bull., 13(5), 525 – 536 (1978); https://doi.org/10.1016/0025-5408(78)90161-7.

Ji Zhang, Zhao Pan, Fei-Fei Guo, et al., “Semiconductor/relaxor 0–3 type composites without thermal depolarization in Bi0.5Na0.5TiO3-based lead-free piezoceramics,” Nature Commun., 6(1), 1 – 10 (2015); https://doi.org/10.1038/ncomms7615.

Ying-Chieh Lee, Tai-Kuang Lee, and Jhen-Hau Jan, “Piezoelectric and microstructures of ZnO-doped (Bi0.5Na0.5TiO3) ceramics,” J. Eur. Ceram. Soc., 31, 3145 – 3152 (2011); https://doi.org/10.1016/j.jeurceramsoc.2011.05.010.

Lukas M. Riemer, K. V. Lalitha, Xijie Jiang, et al., “Stress-induced phase transition in lead-free relaxor ferroelectric composites,” Acta Mater., 136, 271 – 280 (2017); doi: https://doi.org/10.1016/j.actamat.2017.07.008.

Gang Liu, Wentao Jiang, Jingyong Jiao, et al., “The investigation of electrical properties and microstructure of ZnO-doped Ba0.9Sr0.1TiO3 ceramics,” J. Adv. Dielectr., 7(01), 1750007 (2017); https://doi.org/10.1142/S2010135X17500072.

A. Watcharapasorn, S. Jiansirisomboon, and T. Tunkasiri, “Sintering of Fe-doped Bi0.5Na0.5TiO3 at < 1000°C,” Mater. Lett., 61, 14 – 15, 2986 – 2989 (2007); https://doi.org/10.1016/j.matlet.2006.10.059.

Dunmin Lin, K. W. Kwok, and H. L. W. Chan, “Structure and electrical properties of Bi0.5Na0.5TiO3– BaTiO3– Bi0.5Li0.5TiO3 lead-free piezoelectric ceramics,” Solid State Ionics, 178(37 – 38), 1930 – 1937 (2008); https://doi.org/10.1016/j.ssi.2007.12.096.

Hajra Sugato, Sahoo Sushrisangita, Das Rutuparna, and R. N. P. Choudhary, “Structural, dielectric and impedance characteristics of (Bi0.5Na0.5)TiO3 – BaTiO3 electronic system,” J. Alloys Compd., 750, 507 – 514 (2018); https://doi.org/10.1016/j.jallcom.2018.04.010.

MeeraRawat, K. L. Yadav, Amit Kumar, et al., “Structural, dielectric and conductivity properties of Ba2+ doped (Bi0.5Na0.5)TiO3 ceramic,” Adv. Mater. Lett., 3(4), 286 – 292 (2012); https://doi.org/10.5185/amlett.2012.2322.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 2, pp. 56 – 62, February, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mebrek, A., Boukhezar, S., Azzi, A. et al. Microstructural and Electrical Characteristics of (Bi0.5Na0.5)TiO3 – ZnO Piezoceramics. Met Sci Heat Treat 65, 116–121 (2023). https://doi.org/10.1007/s11041-023-00900-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-023-00900-7