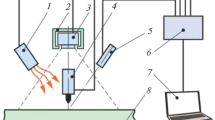

An approach to control of the process of electron beam welding involving simulation, optimization and control of the processes parameters for obtaining a defect-free welded joint with required operating properties from different metallic materials is considered. It is shown that development of multiprocessor control systems equipped with devices for video surveillance of the molten pool makes it possible to create production systems based on the principles of integrated automation of basic and auxiliary operations. The approach is applicable to various production processes including heat treatment of steels and alloys.

Similar content being viewed by others

References

A. I. Rudskoy, K. N. Volkov, Yu. A. Sokolov, and S. Yu. Kondrat’ev, Digital Production Systems: Technologies, Simulation, Optimization [in Russian], POLITEKh-PRESS, St. Petersburg (2020), 828 p.

A. I. Rudskoy, K. N. Volkov, S. Yu. Kondrat’ev, and Yu. A. Sokolov, Physical Processes and Technologies of Manufacturing Metallic Powders from Melt [in Russian], Izd. Politekh. Univers., St. Petersburg (2018), 610 p.

Yu. A. Sokolov, N. V. Pavlushin, and S. Yu. Kondrat’ev, “New additive technologies based on ion beams,” Russ. Eng. Res., 36(12), 1012 – 1016 (2016).

S. Y. Kondrat’ev, V. I. Gorynin, and V. O. Popov, “Optimization of the parameters of the surface-hardened layer in laser quenching of components,” Welding Int., 26, 8, 629 – 632 (2012).

S. Yu. Kondrat’ev, Yu. I. Morozova, Yu. A. Golubev, et al., “Microstructure and mechanical properties of welds Al – Mg – Si alloys after different modes of impulse friction stir welding,” Met. Sci. Heat Treat., 59(11 – 12), 697 – 702 (2018).

M. Moradi and H. Pasternak, “A Study on the influence of various welding sequence schemes on the gain in strength of square hollow section steel T-joint,” J.Weld. Joint., 35, 41 – 50 (2017).

H. Pasternak, B. Launert, and T. Krausche, “Welding girders with thick plates – fabrication, measurement and simulation,” J. Constr. Steel Res., 115, 407 – 416 (2015).

H. Pasternak, B. Launert, T. Kannengiesser, and M. Rhode, “Advanced residual stress assessment of plate girders through welding simulation,” Proc. Eng., 172, 23 – 30 (2017).

Yu. V. Budkin, E. N. Sivov, and Yu. A. Sokolov, Electron Beam Welding [in Russian], DPK Press, Moscow (2010), 96 p.

S. I. Glazov, A. V. Lyushinskii, V. S. Magnitov, et al., Fundamentals of Electron-Beam and Diffusion Welding Technology [in Russian], NPO “Saturn,” Rybinsk (2001), 284 p.

A. A. Kaidalov, Electron Beam Welding [in Russian], Ékotekhnologiya, Kiev (2004), 260 p.

M. A. Sholokhov, Trajectory Problems in Automatic and Robotic Welding. Methods and Algorithms of Solution, Sensors, Software and Hardware [in Russian], Izd. MGTU Im. N. E. Baumana, Moscow (2015), 168 p.

Z. Fang, D, Xu, and M. Tan “Visual seam tracking system for butt weld of thin plate,” Int. J. Adv. Manuf. Technol., 49, 519 – 526 (2010).

H. Shen, T. Lin, and L. Li, “Real-time seam tracking technology of welding robot with visual sensing,” J. Intell. Robot. Syst., 59, 283 – 298 (2010).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov No. 10, Pp. 39 – 44, October 2022

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sokolov, Y., Pavlushin, N.V. Special Features of Control of the Process of Electron Beam Welding. Met Sci Heat Treat 64, 573–578 (2023). https://doi.org/10.1007/s11041-023-00852-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-023-00852-y