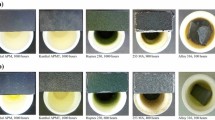

Surface layers of alloys Al – 5% Si, Al – 10% Si and Al – 20% Si after electron beam treatment with different energy densities (10, 30 and 50 J/m2 ) are studied. X-ray diffraction phase analysis is used to determine the phase composition of a surface layer and phase lattice constant after irradiation and in the initial condition. It is shown that irradiation of Al – Si alloys with an electron beam is accompanied by changes in phase lattice constants within a surface layer, which may be connected with changes in alloying element concentration.

Similar content being viewed by others

References

J. M. Poate, G. Foti, and D. C. Jacobson, Surface Modification and Alloying by Laser, Ion, and Electron Beams, Springer, Berlin (2013).

C. M. Abreu, M. J. Cristóbal, R. Figueroa, et al., “Evolution of corrosion behavior for AA7075 aluminum alloy implanted with nitrogen,” Nuclear Instruments and Methods in Physics Research Section B: Beam Inter-actions with Materials and Atoms, 442, 1 – 12 (2019).

N. V. Gushchina, V. V. Ovchinnikov, S. M. Mozharovsky, and L. I. Kaigorodova, “Restoration of plasticity of cold-deformed aluminum alloy by short-term irradiation with accelerated Ar+ions,” Surf. Coat. Technol., 389, 125504 (2020).

Y. Otani and S. Sasaki, “Effects of the addition of silicon to 7075 aluminum alloy on microstructure, mechanical properties, and selective laser melting processability,” Mater. Sci. Eng. A, 777, 139079 (2020).

S. Lei, G. Yang, X.Wang, et al., “High energy femtosecond laser peening of 2024 aluminum alloy,” Proc. CIRP, 74, 357 – 361 (2018).

J. Cai, Q. Guan, P. Lv, et al., “Crater formation on the surface of pure metal and alloy irradiated by high current pulsed electron beam,” High Temp. Mater. Process., 37, 777 – 784 (2018).

J. Cai, L. Ji, S. Yang, et al., “Deformation mechanism and microstructures on polycrystalline aluminum induced by high-current pulsed electron beam,” Chin. Sci. Bull., 58, 2507 – 2511 (2013).

Y. Qin, C. Dong, Z. F. Song, et al., “Deep modification of materials by thermal stress wave generated by irradiation of high-current pulsed electron beams,” J. Vac. Sci. Technol. A, 27, 430 – 435 (2009).

J. Cai, Q. F. Guan, X. L Hou, et al., “Isothermal oxidation behaviour of thermal barrier coatings with CoCrAlY bond coat irradiated by high-current pulsed electron beam,” Appl. Surf. Sci., 317, 360 – 369 (2014).

Z. Y. Han, L. Ji, J. Cai, et al., “Surface nanocrystallization of 3Cr13 stainless steel induced by high-current pulsed electron beam irradiation,” J. Nanomater., 603586 (2013).

J. Cai, S. Z. Yang, L. Ji, et al., “Surface microstructure and high temperature oxidation resistance of thermal sprayed CoCrAlY coating irradiated by high current pulsed electron beam,” Surf. Coat. Technol., 251, 217 – 225 (2014).

Q. F. Guan, P. L. Yang, H. Zou, and G. T. Zou, “Nanocrystalline and amorphous surface structure of 0.45% C steel produced by high current pulsed electron beam,” J. Mater. Sci., 41, 479 – 483 (2006).

D. Zaguliaev, V. Gromov, Yu. Rubannikova, et al., “Structure and phase states modification of Al – 11Si – 2Cu alloy processed by ion-plasma jet and pulsed electron beam,” Surf. Coat. Technol., 383, 125246 (2020).

Yu. F. Ivanov, V. E. Gromov, D. V. Zagulyaev, et al., “Nanostructure formation of hypoeutectic silumin by electron ion-plasma methods,” J. Phys.: Conf. Ser., 1393, 012091 (2019).

N. N. Koval’ and Yu. F. Ivanov (eds.), Steel Structural Surface Layer Evolution Subjected to Elecron0Ion-Plasma Treatment [in Russian], Izd. NTL, Tomsk (2016).

N. S. Grigor’ev and E. Z. Meilikhov (eds.), Physical Values: Handbook [in Russian] Énergoatomizdat, Moscow (1991).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 5, pp. 26 – 29, May, 2022.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shlyarova, Y.A., Zagulyaev, D.V., Ivanov, Y.F. et al. Change in Phase Lattice Spacing in Al – Si Alloys After Electron-Beam Treatment. Met Sci Heat Treat 64, 268–271 (2022). https://doi.org/10.1007/s11041-022-00798-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-022-00798-7