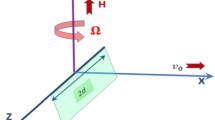

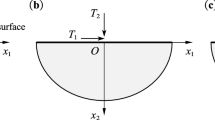

The method of smooth particle hydrodynamics and the ANSYS AUTODYN software are used to reproduce the main phenomena accompanying high-velocity collision of plates fabricated from iron and copper of commercial purity. The maximum true strain of the surface layers is determined to attain ε = 5 or higher values. It is shown experimentally that defects with a length comparable to the thickness of the original plates do not form under welding by optimum modes. Growth in the strength properties is a factor promoting formation of bands of localized flow under rapid loading. Defects of this kind correspond to the behavior of positive feedback loops. The width of the bands arising under explosion welding of plates from a two-phase (α + β) titanium alloy VT23 ranges from units to tens of micrometers.

Similar content being viewed by others

References

A. A. Deribas, The Physics of Hardening and Explosion Welding [in Russian], Nauka, Novosibirsk (1980), 224 p.

B. Crossland, Explosive Welding of Metals and Its Application, Oxford Series of Advanced Manufacturing 2 (1982), 233 p.

V. S. Sedykh and N. N. Kazak, Explosion Welding and Properties of Welded Joints [in Russian], Mashinostroenie, Moscow (1971), 72 p.

S. V. Kuz’min, V. I. Lysak, E. A. Chugunov, and A. P. Peev, “Formation of joint in explosion welding,” Avtomat. Svarka, No. 11, 25 – 29 (2000).

S. V. Kuz’min, V. I. Lysak, V. V. Rybin, and A. P. Peev, “Special features of plastic deformation of the metal of the near-weld zone in explosion welding of dissimilar materials,” Izv. Volgograd. Gos. Tekh. Univ., No. 5, 4 – 11 (2010).

V. V. Rybin, E. A. Ushanova, S. V. Kuz’min, and V. P. Lysak, “Nature of plastic flow of metals in the near-contact zone in explosion welding,” Pis’ma Zh. Tekh. Fiz., 37(23), 26 – 33 (2011).

M. A. Meyers, Dynamic Behavior of Materials, John Wiley & Sons, New York (1994), 668 p.

I. D. Zakharenko, Explosion Welding of Metals [in Russian], Navuka i Tekhnika, Minsk (1990), 205 p.

Yu. A. Konon, L. B. Pervukhin, and A. D. Chudnovskii, Explosion Welding [in Russian], Mashinostroenie, Moscow (1987), 216 p.

V. I. Lysak and S. V. Kuz’min, Explosion Welding. A Monograph [in Russian], Mashinostroenie, Moscow (2005), 543 p.

A. Nassiri and B. Kinsey, “Numerical studies on high-velocity impact welding: smoothed particle hydrodynamics (SPH) and arbitrary Lagrangian-Eulerian (ALE),” J. Manuf. Proc., 24(1), 376 – 381 (2016).

I. A. Bataev, “Formation of structure of explosion-welded materials: experimental studies and numerical simulation,” Obrab. Met.: Tekhnol. Oborud. Instr., No. 4(77), 55 – 67 (2017) (doi: https://doi.org/10.17212/1994-6309-2017-4-55-67).

A. Nassiri, A. Vivek, T. Abke, et al., “Depiction of interfacial morphology in impact welded Ti/Cu bimetallic systems using smoothed particle hydrodynamics,” Appl. Phys. Lett., 110(23), 231601 (2017) (doi: https://doi.org/10.1063/1.4984742).

T. Lee, A. Nassiri, T. Dittrich, et al., “Microstructure development in impact welding of a model system,” Scr. Mater., 178, 203 – 206 (2020) (doi: https://doi.org/10.1016/j.scriptamat.2019.11.031).

J. Feng, P. Chen, Q. Zhou, et al., “Numerical simulation of explosive welding using smoothed particle hydrodynamics method,” Int. J. Multiphys., 11(3), 315 – 326 (2017) (doi: https://doi.org/10.21152/1750-9548.11.3.315).

A. Mori, S. Tanaka, and K. Hokamoto, “Optical observation of metal jet generated by high speed inclined collision,” in: Select. Pap. 31st Int. Congr. “High-Speed Imaging and Photonics, Int. Soc. Optics and Photonics (2017), V. 10328, P. 103281Q (doi: https://doi.org/10.1117/12.2270473).

I. A. Bataev, S. Tanaka, Q. Zhou, et al., “Towards better understanding of explosive welding by combination of numerical simulation and experimental study,” Mater. Des., 169, 107649 (2019) (doi: https://doi.org/10.1016/j.matdes.2019.107649).

A. E. Kheifeits, V. I. Zel’dovich, N. Y. Frolova, et al., “Phase and structural transformations in a low-carbon steel that occur upon the collapse of a cylindrical shell,” Phys. Met. Metallogr., 118(7), 681 – 690 (2017).

A. E. Kheifeits, N. Yu. Frolova, V. I. Zel’dovich, et al., “Deformation- temperature processes occurring under collapse of thick cylindrical shell from steel 20,” Fiz. Met. Metalloved., 116(3), 300 – 308 (2015).

L. M. Gurevich, Yu. P. Tykov, and O. S. Kiselev., “Laws of formation of structural and mechanical heterogeneity in explosion welding of aluminum to titanium,” Svar. Proizvod., No. 2, 14 – 18 (2013).

D. V. Lazurenko, I. A. Bataev, V. I. Mali, et al., “Structural transformations occurring in explosion welding of alloy steel and high-strength titanium,” Fiz. Met. Metalloved., 119(5), 495 – 503 (2018) (doi: https://doi.org/10.7868/S0015323018050091).

I. A. Bataev, T. S. Ogneva, A. A. Bataev, et al., “Explosively welded multilayer Ni – Al composites,” Mater. Des., 88, 1082 – 1087 (2015) (doi: https://doi.org/10.1016/j.matdes.2015.09.103).

I. A. Bataev, D. V. Lazurenko, Yu. N. Malyutina, et al., “Ultrahigh cooing rates at the interface of explosively welded materials and their effect on the formation of the structure of mixing zones,” Comb., Expl., Shock Waves, 54(2), 238 – 245 (2018) (doi: https://doi.org/10.1134/S0010508218020132.u).

The work has been performed in accordance with the Federal Assignment of the Ministry of Education and Science of the Russian Federation (project FSUN-2020-0014(2019-0931)) “Investigation of Metastable Structures Formed on Surfaces and Interfaces of Materials under Extreme External Impact.”

The studies have been conducted using the equipment of the common access center “Structure, Mechanical and Physical Properties of Materials” of the Novosibirsk State Technical University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 12, pp. 41 – 47, December, 2021.

Rights and permissions

About this article

Cite this article

Ryabinkina, P.A., Emurlaeva, Y.Y., Bataev, I.A. et al. Inhomogeneity of Plastic Flow Accompanying Rapid Loading of Metallic Materials. Met Sci Heat Treat 63, 674–680 (2022). https://doi.org/10.1007/s11041-022-00747-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-022-00747-4