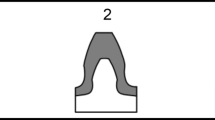

Gears of module 2.5 from steel EN24 are studied after induction hardening at different powers (30 – 55 W). The effect of the hardening on the microstructure, microhardness, residual stresses and distortion of the geometry of the gears is determined. The hardening mode providing minimum distortion of the gear size is suggested.

Similar content being viewed by others

References

P. J. Fernandes and C. Mcduling, “Surface contact fatigue failures in gears,” Eng. Fail. Anal., 4(2), 99 – 107 (1997).

P. J. Fernandes, “Tooth bending fatigue failures in gears,” Eng. Fail. Anal., 3(3), 219 – 225 (1996).

M. J. Schneider and M. S. Chatterjee, Introduction to Surface Hardening of Steels, ASM Handbook (2013), pp. 389 – 398.

K. Matsui, H. Eto, K. Yukitake, et al., “Increase in fatigue limit of gears by compound surface refining using vacuum carburizing, contour induction hardening and double shot peening,” JSME Int. J., Ser. A: Solid Mech. Mater. Eng., 45(2), 290 – 297 (2002).

L. Bertini and V. Fontanari, “Fatigue behaviour of induction hardened notched components,” Int. J. Fatigue, 21(6), 611 – 617 (1999).

A. D. Da Silva, T. A. Pedrosa, J. L. Gonzalez Mendez, et al., “Distortion in quenching an AISI 4140 C-ring — Predictions and experiments,” Mater. Design, 42, 55 – 61 (2012).

A. Sugianto, M. Narazaki, M. Kogawara, et al., “Numerical simulation and experimental verification of carburizing-quenching process of SCr420H steel helical gear,” J. Mater. Proc. Technol., 209(7), 3597 – 3609 (2009).

M. Benedetti, V. Fontanari, B. R. Hohn, et al., “Influence of shot peening on bending tooth fatigue limit of case hardened gears,” Int. J. Fatigue, 24(11), 1127 – 1136 (2002).

V. Rudnev, “Induction hardening of gears and critical components,” Gear Tech., 58 – 63 (2008).

S. Da Sun, Q. Liu, M. Brandt, et al., “Effect of laser clad repair on the fatigue behaviour of ultra-high strength AISI 4340 steel,” Mater. Sci. Eng. A, 606, 46 – 57 (2014).

A. Sahoo and P. Mishra, “A response surface methodology and desirability approach for predictive modeling and optimization of cutting temperature in machining hardened steel,” J. Indus. Eng. Int., 5(3), 407 – 416 (2014).

M. Narazaki, G. E. Totten, and G. M.Webster, Hardening by Reheating and Quenching, ASM International, Materials Park, OH (2002), pp. 248 – 295.

H. W. Zoch, “From single production step to entire process chain — the global approach of distortion,” Eng. Mat.-wiss. u. Werkstofftech, 37(1), 6 – 10 (2006).

D. Klein, M. Seifert, and K. D. Thoben, “Taking the distortion of component parts along a manufacturing chain into consideration during planning,” Eng. Mat.-wiss. u. Werkstofftech, 40, 349 – 353 (2009).

J. Yi, M. Gharghouri, P. Bocher, et al., “Distortion and residual stress measurements of induction hardened AISI 4340 discs,” Mater. Chem. Phys., 142(1), 248 – 258 (2013).

S. Raadnui, “Spur gear wear analysis as applied for tribological based predictive maintenance diagnostics,” Wear, 426, 1748 – 1760 (2019).

A. Muniyappa, S. Chandramohan, and S. Seethapathy, “Detection and diagnosis of gear tooth wear through metallurgical and oil analysis,” Tribo Online, 5(2), 102 – 110 (2010).

B. Zhang, H. Liu, H. Bai, et al., “Ratchetting — multiaxial fatigue damage analysis in gear rolling contact considering tooth surface roughness,” Wear, 428, 137 – 146 (2019).

H. Liu, H. Liu, C. Zhu, et al., “A review on micropitting studies of steel gears,” Coat., 42, 1 – 27 (2019).

M. Fitzpatrick, T. Fry, and P. Holdway, NPL Good Practice Guide No. 52: Determination of Residual Stresses by X-Ray Diffraction, Issue 2, NPL Great Britain, (2005).

O. Anderoglu, Residual Stress Measurement Using X-Ray Diffraction (Dissertation), Texas A&M University (2005).

M. E. Hilley, J. A. Larson, C. F. Jatczak, et al., Residual Stress Measurement by x-ray Diffraction-SAE J784a, Soc. Auto. Eng. Incorp., New York (1971).

ASTM E. 915: Standard Test Method for Verifying the Alignment of x-ray Diffraction Instrumentation for Residual Stress Measurement, ASTM Int., West Conshohocken, PA (2003).

V. F. Zackay, E. R. Parker, D. Fahr, et al., “The enhancement of ductility in high-strength steels,” ASM Transac. Quart., 60(2), 252 – 259 (1967).

W.W. Gerberich, P. L. Hemmings, M. D. Merz, et al., “Preliminary toughness results on trip steel,” in: LBNL Report: UCRL-18203, Lawrence Berkeley National Laboratory (1968), pp. 1 – 15.

C. F. Jatczak, “Retained austenite and its measurement by x-ray diffraction,” SAE Transac., 1657 – 1676 (1980).

ASTM E. 975-03: Standard Practice for x-ray Determination of Retained Austenite in Steel with Near Random Crystallographic Orientation, ASTM, West Conshohocken, PA (2008).

J. D. Verhoeven, Steel Metallurgy for the Non-Metallurgist, ASM Int. (2007), pp. 99 – 105.

ASM Handbook, Vol. 4, Heat Treating, ASM Int. (1991), V. 4, p. 211.

W. D. Callister and D. G. Rethwisch, Materials Science and Engineering: An Introduction, John Wiley & Sons, New York (2007).

F. J. Humphreys and M. Hatherly, “Chap. 11, Grain growth following recrystallization,” in: Recrystallization and Related Annealing Phenomena (2007) pp. 333 – 378.

V. Rudnev, D. Loveless, and R. L. Cook, in: Handbook of Induction Heating, CRC Press (2017).

S. Raadnui, “Spur gear wear analysis as applied for tribological based predictive maintenance diagnostics,” Wear, 426, 1748 – 1760 (2019).

H. Kristoffersen and P. Vomacka, “Influence of process parameters for induction hardening on residual stresses,” Mater. Design, 22(8), 637 – 644 (2001).

N. L. Loh and W. Siewl, “Residual stress profiles of plasma nitride steels,” Surf. Eng., 15(2), 137 – 142 (1999).

L. D. Barlow and M. Du Toit, “Effect of the austenitising heat treatment on the microstructure and hardness of martensitic stainless steel AISI 420,” J. Mater. Eng. Perform., 21(7), 1327 – 1336 (2012).

J. B. Lee, N. Kang, J. T. Park, et al., “Kinetics of carbide formation for quenching and tempering steels during high-frequency induction heat treatment,” Mater. Chem. Phys., 129(1 – 2), 365 – 370 (2011).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 8, pp. 48 – 55, August, 2021.

Rights and permissions

About this article

Cite this article

Navin, R.I., Babu, P.D., Marimuthu, P. et al. Distribution of Residual Compressive Stresses in Induction Hardened Steel Gears: Effect of Parameters on Distortion, Hardness and Phase Composition. Met Sci Heat Treat 63, 449–455 (2021). https://doi.org/10.1007/s11041-021-00710-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-021-00710-9