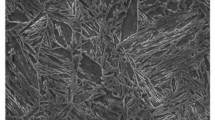

A process of hardening of steel 16Kh3NVFMB-Sh involving vacuum carburizing and subsequent hardening heat treatment is studied. It is shown that in order to obtain an optimum phase composition and, as a consequence, high operating properties, the steel should be subjected after carburizing to high tempering for formation of a fine ferrite-carbide structure. The treatment should be finished with quenching after the second heating, cold treatment and low tempering.

Similar content being viewed by others

References

W. Grafen and B. Edenhofer, “Acetylene low-pressure carburizing — a novel and superior carburizing technology,” Heat Treat. Met., 26(4), 79 – 85 (1999).

F. J. Otto and D. H. Herring, “Vacuum carburizing of aerospace and automotive materials,” Heat Treat. Progr., 5(1), 33 – 37 (2005).

P. Kula, J. Olejnik, and J. Kowalewski, “New vacuum carburizing technology,” Heat Treat. Progr., 1(1), 57 – 65 (2001).

N. M. Ryzhov, A. E. Smirnov, and R. S. Fakhurtdinov, “Control of carbon saturation of diffusion layer in vacuum carburizing of heat-resistant steels,” Metal Sci. Heat Treat., 46(7 – 8), 340 – 344 (2004).

M. Yu. Semenov, I. N. Gavrilin, and M. Yu. Ryzhova, “Computation-based analysis of the methods of hardening of gears from heat-resistant steels,” Metal Sci. Heat Treat., 56(1 – 2), 45 – 49 (2014).

A. E. Smirnov and M. Yu. Semenov, “Application of vacuum heat and thermochemical treatment to hardening of highly loaded parts of machines, facilities and tools,” Nauka Obraz., MGTU Im. Baumana, Electr. Zh., No. 2 (2014) (DOI: https://doi.org/10.7463/0214.0700036; access date Nov. 25, 2019).

A. L. Golovskoy, Optimization of the Process of Vacuum Carburizing of Steels for Bore Bits, Author’s Abstract of Candidate’s Thesis [in Russian], SGTU, Samara (2006), 149 p.

A. E. Smirnov, “Optimization of technological factors of vacuum carbonitriding of complexly alloyed martensitic steels,” Prob. Chern. Metall. Materialoved., No. 2, 13 – 19 (2019).

S. S. Gorelik, Yu. A. Skakov, and L. N. Rastorgueva, X-ray and Electrooptic Analysis [in Russian], MISiS, Moscow (1994), 328 p.

N. M. Ryzhov, M. Yu. Semenov, R. S. Fakhurtdinov, and E. A. Smirnov, “A model of diffusion growth of carbide-phase particles in the carburized layer of heat-resistant steels,” Metal Sci. Heat Treat., 40(9 – 10), 374 – 377 (1998).

A. E. Smirnov, Development of Methods for Active Control and Automation of the Process of Ion Carburizing of Alloy Steels, Author’s Abstract of Candidate’s Thesis [in Russian], MGTU Im. Baumana, Moscow (1991), 198 p.

M. Yu. Semenov, “Control of heat-resistant steel carburized layer structure. Part I,” Metal Sci. Heat Treat., 55(5 – 6), 257 – 264 (2013).

A. D. Le Claire and G. Neumann, “Diffusion of impurities in solid metallic elements,” in: H. Mehrer (ed.), Diffusion of Solid Metals and Alloys, Landolt-Bornstein New Series, Springer-Verlag (1990), V. III(26), pp. 85 – 212.

C.Wells,W. Batz, and R. F. Mehl, “Diffusion coefficient of carbon in austenite,” J. of Metals, No. 2, 553 – 560 (1950).

N. M. Ryzhov and M. Yu. Semenov, “Wear resistance of the carburized layer on alloyed steel with excess carbide phase,” J. Frict. Wear, 19(2), 76 – 80 (1998).

L. Tot, Carbides and Nitrides of Transition Metals [Russian translation], Mir, Moscow (1974), 294 p.

G. V. Shcherbedinskii and L. A. Kondratchenko, “Diffusion growth of phases in three-component systems under mutual effect of elements,” in: Protective Coatings on Metals, Coll. Works [in Russian], Naukova Dumka, Kiev (1972), Issue 5, pp. 23 – 31.

G. V. Shcherbedinskii, M. G. Isakov, and V. V. Trubchikov, “Joint saturation and burning of two elements in a three-component alloy at the final rate of heat transfer on the surface,” in: Protective Coatings on Metals, Coll. Works [in Russian], Naukova Dumka, Kiev (1973), Issue 7, pp. 57 – 63.

A. Guinier, The x-ray Radiography of Crystals [Russian translation], Gos. Izd. Fiz. Mat Lit., Moscow (1961), 604 p.

N. M. Ryzhov, A. E. Smirnov, R. S. Fakhurtdinov, et al., “Vacuum carburizing of chromium-nickel steel,” Metal Sci. Heat Treat., 50(1 – 2), 63 – 67 (2008).

A. E. Smirnov, R. S. Fakhurtdinov,M. Y. Ryzhova, et al., “Technological features of vacuum carburizing of low-alloyed steels,” J. Mach. Manuf. Reliab., 48, 167 – 172 (2019).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 9, pp. 45 – 52, September, 2020.

Rights and permissions

About this article

Cite this article

Smirnov, A.E. Control of Phase Composition of Complexly Alloyed High-Temperature Steels Under Vacuum Carburizing and Quenching. Met Sci Heat Treat 62, 586–593 (2021). https://doi.org/10.1007/s11041-021-00607-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-021-00607-7