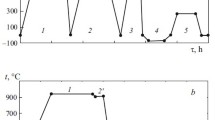

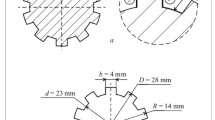

The properties of steel parts after carburizing in low-pressure acetylene are studied. The thickness of the carburized layer, its hardness, the microstructure, and the hardness of the core are determined after carburizing at 900 – 960°C with simultaneous shortening of the process from 104 to 44 min. The data obtained for the diffusion of carbon make it possible to predict the profiles of carbon distribution over the thickness with good enough accuracy.

Similar content being viewed by others

References

R. Stringfellow, “Prediction and control of heat treat distortion of helicopter gears,” in: Aviation Appl. Technol. Directorate, U.S. Army Aviation Troop Command, Report No. USAATCOM TR 95-D-5 (1995).

S. A. Avner, Introduction to Physical Metallurgy, McGraw-Hill, Singapore (1974).

M. Qin, “Vacuum carburising and high pressure gas quenching technology in automotive industry,” Int. Heat Treat. Surf. Eng., 2(3/4), 116 – 120 (2008).

M. Jung, S. Oh, and Y.-K. Lee, “Predictive model for the carbon concentration profile of vacuum carburized steels with acetylene,” Met. Mater. Int., 15(6), 971 – 975 (2009).

M. Sugiyama, K. Ishikawa, and H. Iwata, “Using acetylene for superior performance vacuum carburizing,” in: Ref. Proc. 18th ASM Conf. on Heat Treating, ASM Int. (1998), pp. 49 – 56.

A. Fick, “On liquid diffusion,” London, Edinburgh and Dublin Philos. Mag. J. Sci., X, 30 – 39 (1855).

J. Goldstein and A. E. Moren, “Diffusion modelling of the carburisation process,” Metall. Mater. Trans. A, 9A(11), 1515 – 1525 (1978).

R. Collin, S. Gunnarson, and D. A. Thulin, “Mathematical model for predicting carbon concentration profiles of gas-carburized steel,” J. Iron Steel Inst., 785 – 789 (1972).

T.Wada, H.Wada, J. F. Elliot, and J. Chipman, “Activity of carbon and solubility of carbides in the FCC Fe – Mo – C, Fe – Cr – C, and Fe – V – C alloys,” Metall. Trans., 3(11), 2865 – 2872 (1972).

F. Neumann and B. Person, “Beitrag zur metallurgie der gasaufkohlung — Zusammenhang zwischen dem C-potential der gasphase und des werkstückes unter berücksichtigung der legierungselemente,” Härterei-Technische Mitteilung, 23(4), 296 – 308 (1968).

G. G. Tibbetts, “Diffusivity of carbon in iron and steels at high temperatures,” J. Appl. Phys., 51(9), 4813 – 4816 (1980).

F. E. Harris, “Case depth – An attempt at a practical definition,” Metal Progr., 44, 265 – 272 (1943).

Latrobe Specialty Steel Company. Lescalloy® 16NCD13 Var-Arc® Data Sheet, Latrobe Specialty Steel Company, Latrobe (2007).

A. O. Benscoter and M. J. Perricone, “Marshall’s reagent: origins, modifications and new applications,” Microscopy Soc. Amer.: Microsc. Microanal., 11, Suppl. 2, 76 – 77 (2005) (http://www.cambridge.org/core/journals).

Standard Test Methods for Determining Average Grain Size: ASTM E112-13, ASTM Int., West Conshohocken (2013).

Standard Practice for Microetching Metals and Alloys: ASTM E497-07el, ASTM Int., West Conshohocken (2007).

Standard Methods and Definitions for Mechanical Testing of Steel Products: ASTM A370-14, ASTM Int., West Conshohocken (2014).

Standard Hardness Conversion Tables for Metals Relationship among Brinell Hardness, Vickers Hardness, Rockwell Hardness, Superficial Hardness, Knoop Hardness, Scleroscope Hardness, and Leeb Hardness: ASTM E140-12bel, ASTM Int., West Conshohocken (2012).

M. Sugiyama, “Vacuum carburizing,” J. Jpn. Soc. Heat Treat., 37(3), 154 (1998).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 4, pp. 37 – 43, April, 2020.

Rights and permissions

About this article

Cite this article

Heintzberger, P.J. Influence of the Temperature of Vacuum Carburizing on the Thickness of the Carburized Layer and Properties of Steel Parts. Met Sci Heat Treat 62, 279–284 (2020). https://doi.org/10.1007/s11041-020-00549-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-020-00549-6