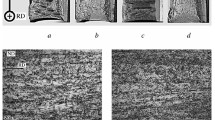

Orientation microscopy (EBSD) is used to study structural and textural states through the thickness of pipe steel strips after a controlled thermomechanical treatment. It is shown that texture formation in the form of a selection of components (3 – 7) with a large number of versions of crystallographic orientations, arising with shear phase transformations in accordance with the orientation ratios, suggests presence within the steel structure of elements limiting the number of possible α′-phase orientations. It is proposed that these elements are special boundaries formed during hot rolling close to boundaries RSU Σ3 and Σ11 between deformed austenite grains.

Similar content being viewed by others

References

W. B. Hutchinson, “ Practical aspects of texture control in low carbon steels,” Mater. Sci. Forum, 157 – 162, 1917 – 1928 (1994).

D. Lindell, “Texture evolution of warm-rolled and annealed 304L and 316L austenitic stainless steels,” IOP Conf. Ser.: Mater. Sci. Eng., 82, Art. No. 012101 (2015).

A. V. Druker, C. Sobrero, V. Fuster, et al., “Is it possible to use rolling methods to improve textures on Fe – Mn – Si shape memory alloys?” Adv. Eng. Mater., 20(4), Art. No. 1700062 (2017).

A. I. Rudskoy, A. A., Kononov, S. Yu. Kondrat’ev, and M. A. Matveev, “Texture formation in hot rolling of electrical anisotropic steel,” Met. Sci. Heat Treat., 60(11 – 12), 689 – 694 (2019).

F. J. Humphreys and M. Hatherly, Recrystallization and Related Annealing Phenomena, ELSEVIER Ltd., Oxford (2004).

O. A. Kaibyshev and R. Z. Valiev, Grain Boundaries and Metal Properties [in Russian], Metallurgiya, Moscow (1987).

K. Khulka, P. Peters, and F. Khaisterkamp, “Trends in the development of steels for large diameter pipes,” Stal’, No. 10, 62 – 67 (1997).

E. Shigeru and N. Naoki, “Development of thermo-mechanical control process (TMCP) and high performance steel in JFE steel,” JFE Tech. Report, No. 20, 1 – 7 (2015).

Yu. D. Morozov, S. Yu. Nastich, M. Yu. Matrosov, and O. N. Chevskaya, “Obtaining high-quality properties of rolled material for large-diameter pipes based on formation of ferrite-bainite microstructure,” Metallurgist, 52, 21 – 28 (2008).

S. Y. Nastich, Y. D. Morozov, V. L. Kornilov, et al., “New steels for pipelines of strength classes K54 – K60 (X70): Production experience at OAO MMK,” Steel in Translation, 39, 431 – 436 (2009).

H. K. Sung, S. Y. Shin, B. Hwang, et al., “Effects of carbon equivalent and cooling rate on tensile and Charpy impact properties of high-strength bainitic steels,” Mater. Sci. Eng. A, 530, 530 – 538 (2011).

Z. J. Xie, X. P. Ma, C. J. Shang, et al., “Nano-sized precipitation and properties of a low carbon niobium micro-alloyed bainitic steel,” Mater. Sci. Eng. A, 641, 37 – 44 (2015).

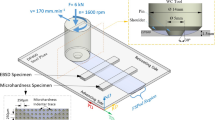

E. A. Goli-Oglu, L. I. Éfron, and Yu. D. Morozov, “Effect of deformation regime in main stages of controlled rolling on pipe steel microstructure,” Met. Sci. Heat Treat., 55(5 – 6), 294 – 297 (2013).

M. L. Lobanov, S. V. Danilov, V. I. Pastukhov, et al., “Effect of cooling rate on the structure of low-carbon steel after controlled thermomechanical treatment,” MiTOM, No. 1, 31 – 37 (2019).

I. Y. Pyshmintsev, A. O. Struin, A. M. Gervasyev, et al., “Effect of bainite crystallographic texture on failure of pipe steel sheets made by controlled thermomechanical treatment,” Metallurgist, 60, 405 – 412 (2016).

M. L. Lobanov, M. D. Borodina, S. V. Danilov, et al., “Texture inheritance on phase transition in low-carbon, low-alloy pipe steel after thermomechanical controlled processing,” Steel in Translation, 47, 710 – 716 (2017).

M.-C. Zhao, K. Yang, and Y. Shan, “The effects of thermo-mechanical control process on microstructures and mechanical properties of a commercial pipeline steel,” Mater. Sci. Eng. A, 335, 14 – 20 (2002).

M. L. Lobanov, G. M. Rusakov, A. A. Redikul’tsev, et al., “Investigation of special misorientations in lath martensite of low-carbon steel using the method of orientation microscopy,” Phys. Met. Metallogr., 117, 254 – 259 (2016).

G. M. Rusakov, M. L. Lobanov, A. A. Redikul’tsev and A. S. Belyaevskikh, “Special misorientations and textural heredity in the commercial alloy Fe – 3% Si,” Phys. Met. Metallogr., 115, 775 – 785. (2014).

B. Hutchinson, L. Ryde, E. Lindh, and K. Tagashira, “Texture in hot rolled austenite and resulting transformation products,” Mater. Sci. Eng. A, 257, 9 – 17 (1998).

X. Yang, Y. Xu, X. Tan, and D. Wu, “Influences of crystallography and delamination on anisotropy of Charpy impact toughness in API X100 pipeline steel,” Mater. Sci. Eng. A, 607, 53 – 62 (2014).

M. L. Lobanov, A. A. Redikul’tsev, G. M. Rusakov, and S. V. Danilov, “Interrelation between the orientations of deformation and recrystallization in hot rolling of anisotropic electrical steel,” Met. Sci. Heat Treat., 57(5 – 6), 492 – 497 (2015).

M. L. Lobanov, Y. N. Loginov, S. V. Danilov, et al. “Effect of hot rolling rate on the structure and texture condition of plates of the Al – Si – Mg alloy system,” Met. Sci. Heat Treat., 60(5 – 6), 329 – 336 (2018).

M. Hölscher, D. Raabe, and K. Lücke, “Relationship between rolling textures and shear textures in F.C.C. and B.C.C. metals,” Acta Metall. Mater., 42, 879 – 886 (1994).

W. Gong, Y. Tomota, A. M. Paradowska, et al., “Effects of ausforming temperature on bainite transformation, microstructure and variant selection in nanobainite steel,” Acta Mater., 61, 4142 – 4154 (2013).

I. Sabirov, I. de Diego-Calderón, J. M. Molina-Aldareguia, et al., “Microstructural design in quenched and partitioned (Q&P) steels to improve their fracture properties,” Mater. Sci. Eng. A,657, 136 – 146 (2016).

M. L. Lobanov, S. V. Danilov, V. I. Pastukhov, et al., “The crystallographic relationship of molybdenum textures after hot rolling and recrystallization,” Mater. Design, 109, 251 – 255 (2016).

V. A. Nekit, S. I. Platov, I. A. Kurbakov, and A. D. Golev, “Experimental study of forward slip and delays during rolling,” Vestn. Magnit. Gos. Tekhn. Univ. im. G. I. Nosova, No. 1(49), 52 – 54 (2015).

The authors are grateful for the support of leading RF universities with the aim of increasing their competitiveness of No. 211 of the RF Government No. 02.A03.21.0006. The authors thank PASO MMK for support and cooperation in organizing research. The work was conducted with support of a stipend from the President of the Russian Federation for project SP-259.2018.1.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 1, pp. 56 – 61, January, 2020.

Rights and permissions

About this article

Cite this article

Platov, S.I., Krasnov, M.L., Urtsev, N.V. et al. Structural and Textural States of Steel 06G2MB Strips After Controlled Thermomechanical Treatment. Met Sci Heat Treat 62, 55–60 (2020). https://doi.org/10.1007/s11041-020-00512-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-020-00512-5