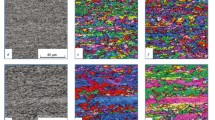

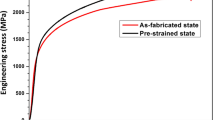

The method of orientation microscopy (EBSD) is used to study the texture of low-carbon, low-alloy pipe steel sheets with a bainitic structure made by controlled thermomechanical processing. The specimens analyzed are inclined or not inclined towards forming separations (secondary cracks) in a fracture during mechanical testing. Formation of separations during failure of steel with a bainitic structure is connected with the presence in the material of regions with uniform orientation (001)<110> extended in the cold rolling direction. Formation of the regions is a consequence of features of γ→α shear transformation that commences at special boundaries between deformed austenite grains.

Similar content being viewed by others

References

K. Khulka, P. Peters, and F. Heisterkamp, “Trends in development of steel for large diameter pipes,” Stal, No. 10, 62–67 (1997).

A. B. Arabaei, “Development of engineering requirements for main gas pipeline metal,” Izv. Vyssh. Uchebn. Zaved., Chern. Met.., No. 7, 3–10 (2010).

M. A. Smirnov, I. Yu. Pyshmintsev, and A. N. Boryakova, “Classification of low-carbon pipe steel microstructure,” Metallurg, No. 7, 41–51 (2010).

G. Mannucci and G. Demofonti, “Control of ductile fracture propagation in X80 gas linepipe,” Thesis Proc. Int. Pipeline Technology Conf., Beijing, China (2010).

I. Yu. Pyshmintsev, A. M. Mal’tseva, A. M. Deras’ev, et al., “Structure and properties of low-carbon steels subjected to pneumatic tests,” Stal, No. 2, 75–81 (2011).

T. Hara, Y. Shinohara, H. Asahi, and Y. Terada, “Effects of microstructure and texture on DWTT properties for high strength line pipe steels,” Proc. 6th IPC2006, Calgary, Alberta, Canada (2006).

R. Ray and J. J. Jonas, “Transformation textures in steels,” Int. Materials Rev., 35, 1–36 (1990).

B. Hutchinson, L. Ryde, E. Lindh, and K. Tagashira, “Texture in hot rolled austenite and resulting transformation products,” Mater. Sci. Eng. A. Struct. Mater. Prop. Microstr. Proces., 257, No. 1, 9–17 (1998).

X. Yang, Y. Xu, X. Tan, and D. Wu, “Influences of crystallography and delamination on anisotropy of Charpy impact toughness in API X100 pipeline steel,” Mater. Sci. Eng. A., 607, No. 23, 53–62 (2014).

E. El-Danaf, M. Baig, A. Almajid, et al., “Mechanical, microstructure and texture characterization of API X65 steel,” Mater. Design., 47, 529–538 (2013).

A. V. Andreeva, Base of Composite Physical Chemistry and Technology, IPRZhR, Moscow (2001).

I. Pyshmintsev, A. Gervasyev, R. H. Petrov, et al., “Crystallographic texture as a factor enabling ductile fracture arrest in high strength pipeline steel,” Mater. Sci. Forum, 702–703, 770–773 (2012).

M. Hölscher, D. Raabe, and K. Lücke, “Relationship between rolling textures and shear textures in F.C.C. and B.C.C. metals,” Acta Metall. Mater., 42, No. 3, 879–886 (1994).

M. A. Strenel’, Yu. G. Andreev, and D. A. Kozlov, “Structure and strength of packet martensite,” MiTOM, No. 4, 10–15 (1999).

V. M. Schastlivtsev, “Features of structure and crystallography of structural steel lath martensite,” Metally, No. 5, 32–41 (2001).

M. L. Lobanov, G. M. Rusakov, A. A. Redikul’tsev, et al., “Study of special misorientations in lath martensite of low-carbon steel by orientation microscopy,” FMM, 117, No. 3, 278–283 (2016).

R. Rementeria, L. Morales-Rivas, M. Kuntz, et al., “On the role of microstructure in governing the fatigue behavior of nanostructured bainitic steels,” Mater. Sci. Eng. A., 630, 71–77 (2015).

E. V. Pereloma, F. Al-Harbi, and A. A. Gazder, “The crystallography of carbide-free bainite in thermo-mechanically processed low Si transformation-induced plasticity steels,” J. Alloys and Comp., 615, 96–110 (2014).

W. Gong, Y. Tomota, Y. Adachi, et al., “Effects of ausforming temperature on bainite transformation, microstructure and variant selection in nanobainite steel,” Acta Mater., 61, 4142–4154 (2013).

M. L. Lobanov, A. A. Redikul’tsev, G. M. Rusakov, and S. V. Danilov, “Correlation of orientations for deformation and recrystallization during hot rolling of electrical engineering anisotropic steel,” MiTOM, No. 8, 44–49 (2015).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 4, pp. 57–63, April, 2016.

Rights and permissions

About this article

Cite this article

Pyshmintsev, I.Y., Struin, A.O., Gervasyev, A.M. et al. Effect of Bainite Crystallographic Texture on Failure of Pipe Steel Sheets Made by Controlled Thermomechanical Treatment. Metallurgist 60, 405–412 (2016). https://doi.org/10.1007/s11015-016-0306-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-016-0306-7