The structure, the strength characteristics and the impact toughness at different temperatures up to –100°C of tubular billets from steel 35 are studied after a thermal deformation treatment involving initial heat hardening, cold plastic deformation by radial forging and subsequent annealing. The regular features of structure formation in steel 35 after the thermal deformation treatment based on cold radial forging are determined. It is shown that formation of macroscopic elements (splits) on the fracture surface affects positively the level of the cold resistance.

Similar content being viewed by others

References

Yu. P. Solntsev, “Current and future steels for cryogenic engineering,” Perspekt. Mater., No. 3, 68 – 81 (1998).

Yu. P. Solntsev, B. S. Ermakov, S. A. Vologzhanina, et al., “Operating capacity of materials of low-temperature equipment. Part 1. Review. Causes of failure and appearance of defects in large-size structures of low-temperature objects,” Vest. Mezhd. Akad. Kholoda, No. 4, 31 – 33 (2004).

S. B. Ermakov, V. V. Kargina, Yu. P. Solntsev, and A. K. Andreev, “Effect of heat treatment and microalloying on cold resistance of steels for North applications,” Metally, No. 4, 66 – 74 (2010).

R. Z. Valiev, A. V. Korznikov, and R. R. Mulyukov, “Structure and properties of ultrafine-grained materials produced by severe plastic deformation,” Mat. Sci. Eng., A168, 141 – 146 (1993).

V. M. Segal, V. I. Reznikov, V. I. Kopylov, et al., Processes of Plastic Structure Formation of Metals [in Russian], Nauka i Tekhnika, Minsk (1994), 232 p.

V. M. Segal, V. I. Reznikov, A. E. Drobyshevskii, and V. I. Kopylov, “Plastic treatment of metals by pure shear,” Izv. Akad. Nauk SSSR, Metally, No. 1, 115 – 123 (1981).

Ya. E. Beigelzimer, “Severe plastic deformation: Method for creating ultrafine-grained structures in metals,” Vost.-Evr. Zh. Pered. Tekhnol., No. 2/1(14), 28 – 31 (2005).

J. Washburn, “Strain hardening,” in: Mechanisms of Hardening of Solids [Russian translation], Metallurgiya, Moscow (1965), 368 p.

P. S. Stepin and G. I. Raab, “A study of the potential of rotary forging for fabrication of materials with ultrafine-grained structure,” Kuzn.-Shtamp. Proizvod., Obrab. Met. Davl., No. 4, 34 – 37 (2012).

G. A. Salishchev, R. G. Zaripova, and A. A. Zakirova “Structure and properties of stainless steels subjected to severe plastic deformation,” Metalloved. Term. Obrab. Met., No. 2, 27 – 32 (2006).

M. V. Markushev, “On the problem of efficiency of some methods of severe plastic deformation for fabricating bulk nanostructured materials,” Pis’ma Mater., No. 1, 36 – 42 (2011).

R. Z. Valiev and I. V. Aleksandrov, Nanostructured Materials Produced by Severe Plastic Deformation [in Russian], Logos, Moscow (2000), 272 p.

S. V. Dobatkin, A. M. Arsenkin, M. A. Popov, and A. N. Kishchenko, “Fabrication of bulk metallic nano- and submicrocrystalline materials by the method of severe plastic deformation,” Metalloved. Term. Obrab. Met., No. 5, 29 – 34 (2005).

A. M. Glezer and L. S. Metlov, “Megaplastic deformation of solid bodies,” Fiz. Tekh. Vysok. Davl., 18(4), 21 – 36 (2008).

A. M. Glezer, A. A. Tamchuk, and D. Bi, “Analysis of high-angle and low-angle grain boundaries in metals subjected to megaplastic deformation,” in: Irreversible Processes in Nature and Engineering, Proc. Eighth All-Russia Conference, Moscow (2005), pp. 148 – 152.

E. A. Pogorilchuk and E. A. Vlasov, “Determination of optimum parameters of production process of radial forging,” Nauka Obraz., MGTU Im. N. E. Baumana, No. 9, 3 (2009).

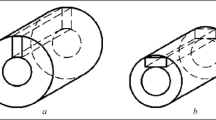

M. Yu. Simonov, G. S. Shaimanov, A. S. Pertsev, et al., “Effect of structure on the thermodynamic crack resistance and special features of the micromechanism of crack growth in steel 35 after cold radial forging,” Metal. Sci. Heat Treat., 58(2), 82 – 90 (2016).

M. Yu. Simonov, G. S. Shaimanov, A. S. Pertsev, et al., “Dynamic crack resistance and structure of a tubular billet from steel 09G2S after thermal deformation treatment,” Metalloved. Term. Obrab. Met., No. 6, 64 – 71 (2017).

Yu. N. Simonov, A. P. Nishta, S. S. Yugay, and A. S. Pertsev, “Refinement of the structure of steel 35 up to the nanolevel aimed at creating materials for high-pressure vessels,” Metalloved. Term. Obrab. Met., No. 11, 7 – 12 (2010).

M. Yu. Simonov, Yu. N. Simonov, and G. S. Shaimanov, “Structural and fractographic features of formation of splits in low-alloy steel subjected to thermal deformation treatment,” Metalloved. Term. Obrab. Met., No. 10, 5 – 15 (2019).

M. N. Georgiev, Yu. N. Simonov, and M. Yu. Simonov, “Effect of the length of the crack and side notches on implementation of conditions of plan strain under impact loading,” Zavod. Lab., Diagn. Mater., 76(9), 56 – 58 (2010).

M. Yu. Simonov, Yu. N. Simonov, A.M. Khanov, and G. S. Shaimanov, “Structure, dynamic crack resistance and fracture mechanisms of quenched and tempered structural steels,” Metalloved. Term. Obrab. Met., No. 11, 32 – 39 (2012.

Yu. M. Simonov, G. S. Shaimanov, and Yu. N. Simonov, “Formation of zones of plastic strain in quenched and tempered steel 09G2S during dynamic tests,” Metalloved. Term. Obrab. Met., No. 12, 44 – 50 (2015).

M. Yu. Simonov, M. N. Gerogiev, G. S. Shaimanov, et al., “Comparative analysis of zones of plastic strain, dynamic crack resistance, structure and micromechanisms of crack growth of steels 09G2S, 25 and 40 in high-ductility condition,” Metalloved. Term. Obrab. Met., No. 2, 39 – 48 (2016).

M. Yu. Simonov, G. S. Shaimanov, Yu. N. Simonov, and A. M. Khanov, “Possibility of prediction of the properties of high-ductility materials by complex analysis of the sizes of zones of plastic strain and other parameters of steel 09G2S,” Metalloved. Term. Obrab. Met., No. 2, 49 – 54 (2016).

M. Yu. Simonov, O. B. Naimark, Yu. N. Simonov, et al., “Structural aspects of zones of plastic strain. Part I. Effect of adiabatic shear,” Metalloved. Term. Obrab. Met., No. 10, 43 – 53 (2019).

M. Yu. Simonov, “Structural aspects of zones of plastic strain. Part II. Effect of mass transfer,” Metalloved. Term. Obrab. Met., No. 10, 54 – 63 (2019).

The work has been performed according to Project No. 11.8213.2017/8.9 within the base part of the state assignment to higher educational organizations in the sphere of scientific activity and with financial support of the Ministry of Education and Science of Russia.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 10, pp. 15 – 25, October, 2019.

Rights and permissions

About this article

Cite this article

Simonov, M.Y., Pertsev, A.S., Shaimanov, G.S. et al. Cold Resistance of Structural Steel Subjected to Cold Radial Forging. Met Sci Heat Treat 61, 601–609 (2020). https://doi.org/10.1007/s11041-020-00467-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-020-00467-7