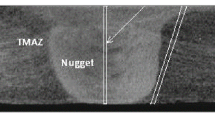

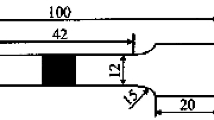

Friction-stir-welded joints of 16-mm-thick plates of AA7075 aluminum alloy have been studied. The macrostructure of the weld region over the thickness of the plates and microstructures of various regions of the welded joint were determined using optical and transmission electron microscopes. Tensile testing of the welded samples was conducted, and the average values of the ultimate strength and yield point, as well as relative elongation were calculated. The Vickers hardness profiles in the middle of the cross-section of the welded joint were measured. Friction stir welding with forced cooling (by a compressed air flow or water immersion) was tested to reduce heat damage and improve mechanical properties. The efficiency of such welding has been demonstrated.

Similar content being viewed by others

References

K. Abhay and K. Sreekumar, “Metallurgical studies on cracked Al – 5.5Zn – 2.5Mg – 1.5Cu aluminum alloy injector disc of turbine rotor,” J. Failure Analysis Prevent., 4, 327 – 332 (2008).

W. M. Thomas, E. D. Nicholas, J. C. Needham, M. G. Church, P. Temple-Smith, and C. J. Dawes, GB Patent Application No. 9125978.8, December (1991).

J. Q. Sua, T.W. Nelson, and C. J. Sterling, “Microstructure evolution during FSW/FSP of high strength aluminum alloys,” Mater. Sci. Eng. A, 405, 277 – 286 (2005).

H. Fujii, L. Cui, M. Maeda, and K. Nogi, “Effect of tool shape on mechanical properties and microstructure of friction stir welded aluminum alloys,” Mater. Sci. Eng. A, 419, 25 – 31 (2006).

H. B. Chen, K. Yan, T. Lin, S. B. Chen, C. Y. Jiang, and Y. Zhao, “The investigation of typical welding defects for 5456 aluminum alloy friction stir welds,” Mater. Sci. Eng. A, 433, 64 – 69 (2006).

R. S. Mishra and Z. Y. Ma, “Friction stir welding and processing,” Mater. Sci. Eng. R, 50, 1 – 78 (2005).

K. A. A. Hassan, P. B. Prangnell, A. F. Norman, D. A. Price, and S. W. Williams, “Effect of welding parameters on nugget zone microstructure and properties in high strength aluminum alloy friction stir welds,” Sci. Technol. Weld. Join., 8, 257 – 268 (2003).

C. G. Rhodes, M. W. Mahoney, W. H. Bingel, R. A. Spurling, and C. C. Bampton, “Effects of friction stir welding on microstructure of 7075 aluminum,” Scr. Mater., 36, 69 – 75 (1997).

K. V. Jata, K. K. Sankaran, and J. J. Ruschau, “Friction-stir welding effects on microstructure and fatigue of aluminum alloy 7050-T7451,” Metall. Mater. Trans. A, 31A, 2181 – 2192 (2000).

M. W. Mahoney, C. G. Rhodes, J. G. Flintoff, R. A. Spurling, and W. H. Bingel, “Properties of friction-stir-welded 7075 T651 aluminum,” Metall. Mater. Trans. A, 29A, 1955 – 1964 (1998).

M. Peel, A. Steuwer, M. Preuss, and P. J. Withers, “Microstructure, mechanical properties and residual stresses as a function of welding speed in aluminum AA5083 friction stir welds,” Acta Mater., 51, 4791 – 4801 (2003).

A. P. Reynolds, W. D. Lockwood, and T. U. Seidel, “Processing-property correlation in friction stir welds,” Mater. Sci. Forum, 331 – 337, 1719 – 1724 (2000).

H. J. Liu, H. Fujii, M. Maeda, and K. Nogi, “Tensile properties and fracture locations of friction-stir-welded joints of 2017-T351 aluminum alloy,” J. Mater. Proc. Technol., 142, 692 – 696 (2003).

B. Yang, J. Yan, M. A. Sutton, and A. P. Reynolds, “Banded microstructure in AA2024-T351 and AA2524-T351 aluminum friction stir welds, Part I. Metallurgical studies,” Mater. Sci. Eng. A, 364, 55 – 65 (2004).

K. A. A. Hassan, A. F. Norman, and P. B. Prangnell, “The stability of the nugget zone grain structure in AA7010 alloy friction stir welds during solution treatment,” Mater. Sci. Forum, 396 – 402, 1549 – 1554 (2002).

K. A. A. Hassan, A. F. Norman, and P. B. Prangnell, “The effect of welding conditions on the microstructure and mechanical properties of the nugget zone in AA7010 alloy friction stir welds,” in: Third International Symposium on Friction Stir Welding, Kobe, Japan (2001).

K. V. Jata, “Friction stir welding of high strength aluminum alloys,” Mater. Sci. Forum, 331 – 337, 1701 – 1712 (2000).

J. D. Robson, A. Sullivan, H. R. Shercliff, and G. McShane, “Microstructural evolution during friction stir welding of AA7449,” in: Fifth International Friction Stir Welding Symposium, Metz, France (2004).

Y. C. Chen, H. J. Liu, and J. C. Feng, “Effect of post-weld heat treatment on the mechanical properties of 2219-O friction stir welded joints,” J. Mater. Sci., 41(1), 297 – 299 (2006).

H. J. Liu, Y. C. Chen, and J. C. Feng, “Effect of heat treatment on tensile properties of friction stir welded joints of 2219-T6 aluminum alloy,” Mater. Sci. Technol., 22(2), 237 – 241 (2006).

S. Benavides, Y. Li, L. E. Murr, D. Brown, and J. C. McClure, “Low-temperature friction-stir welding of 2024 aluminum,” Scr. Mater., 41, 809 – 815 (1999).

P. Staron, M. Kocak, and S. Williams, “Residual stresses in friction stir welded Al sheets,” Appl. Phys. A, 74, 1161 – 1162 (2002).

T. W. Nelson, R. J. Steel, and W. J. Arbegast, “In situ thermal studies and post-weld mechanical properties of friction stir welds in age hardenable aluminum alloys,” Sci. Technol. Weld. Join., 8(4), 283 – 288 (2003).

J. Q. Su, T. W. Nelson, and C. J. Sterling, “A new route to bulk nanocrystalline materials,” J. Mater. Res., 18(8), 1757 – 1760 (2003).

L. Fratini, G. Buffa, and R. Shivpuri, “In-process heat treatments to improve FS-welded butt joints,” Int. J. Adv. Manuf. Technol., 43, 664 – 670 (2009).

L. Fratini, G. Buffa, and R. Shivpuri, “Mechanical and metallurgical effects of in process cooling during friction stir welding of AA7075-T6 butt joints,” Acta Mater., 58, 2056 – 2067 (2010).

H. J. Liu, H. J. Zhang, Y. X. Huang, and L. Yu, “Mechanical properties of underwater friction stir welded 2219 aluminum alloy,” Trans. Nonfer. Met. Soc. China, 20, 1387 – 1391 (2010).

P. Upadhyay and A. P. Reynolds, “Effects of thermal boundary conditions in friction stir welded AA7050-T7 sheets,” Mater. Sci. Eng. A, 527, 1537 – 1543 (2010).

H. J. Zhang, H. J. Liu, and L. Yu, “Microstructure and mechanical properties as a function of rotation speed in underwater friction stir welded aluminum alloy joints,” Mater. Design, 32, 4402 – 4407 (2011).

C. Sharma, D. K. Dwivedi, and P. Kumar, “Influence of in-process cooling on tensile behavior of friction stir welded joints of AA7039,” Mater. Sci. Eng. A, 556, 479 – 487 (2012).

Z. Zhang, B. L. Xiao, and Z. Y. Ma, “Influence of water cooling on microstructure and mechanical properties of friction stir welded 2014Al-T6 joints,” Mater. Sci. Eng. A, 614, 6 – 15 (2014).

H. J. Zhang and H. J. Liu, “Mathematical model and optimization for underwater friction stir welding of a heat-treatable aluminum alloy,” Mater. Design, 45, 206 – 211 (2013).

H. Papahn, P. Bahemmat, and M. Haghpanahi, “Study on governing parameters of thermal history during underwater friction stir welding,” Int. J. Adv. Manuf. Technol., 78, 1101 – 1111 (2015).

T. Srinivasa Rao, G. Madhusudhan Reddy, and S. R. Koteswara Rao, “Microstructure and mechanical properties of friction stir welded AA7075-T651 aluminum alloy thick plates,” Trans. Nonfer. Met. Soc. China, 25, 1170 – 1178 (2015).

T. Srinivasa Rao, G. Madhusudhan Reddy, G. Srinivasa Rao, and S. R. Koteswara Rao, “Studies on salt fog corrosion behavior of friction stir welded AA7075-T651 aluminum alloy,” Int. J. Mater. Res., 105, 375 – 385 (2014).

M. Selvaraj, V. Murali, and S. R. Koteswara Rao, “Mechanism of weld formation during friction stir welding of aluminum alloy,” Mater. Manuf. Proc., 28, 595 – 600 (2013).

J. A. Wert, “Identification of precipitates in 7075 Al after hightemperature aging,” Scr. Mater., 15, 445 – 447 (1981).

G.W. Lorimer, “Precipitation in aluminum alloys,” in: K. C. Russell and H. I. Aaronson (eds.), Precipitation Processes in Solids, Metallurgical Society of AIME, Warrendale PA (1978), pp. 87 – 119.

The authors acknowledge the financial support from the Armament Research Board, DRDO, Ministry of Defence, India, through an R&D project No. ARMREB/MAA/2012/142. The authors acknowledge the support provided by the DMRL, Hyderabad, for conducting friction stir welding trails. The authors would like to thank Dr. M. Selvaraj, Associate Professor, SSN College of Engineering, Chennai, for his help in computing the thermal cycles.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 6, pp. 48 – 55, June, 2019.

Rights and permissions

About this article

Cite this article

Rao, T.S., Rao, S.R.K. & Reddy, G.M. Microstructure and Fracturing Behavior of AA7075–T651 Aluminum Alloy Cooled During Friction Stir Welding. Met Sci Heat Treat 61, 379–386 (2019). https://doi.org/10.1007/s11041-019-00433-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-019-00433-y