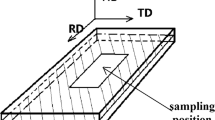

Variation of the texture and grain state of refractory nickel alloy ZhS6K-VI synthesized by the method of selective laser melting is studied as a function of the sintering mode, the type of hatching and heat treatment. Two types of hatching are employed, i.e., diagonal-island and checkerboard ones. The texture is studied. Orientation maps of fragments are plotted with the help of the EBSD method. Regular features of structure formation depending on the synthesis mode are determined.

Similar content being viewed by others

References

E. N. Kablov, “Innovative developments of FGUP “VIAM” GNTs RF on implementation of “Strategic Directions of Advancement of Materials and Processing Technologies for up to 2030,” Aviats. Mater. Tekhnol., No. 1, 3 – 33 (2015), DOI: https://doi.org/10.18577/2071-9140-2015-0-1-3-33.

E. N. Kablov, Tendencies and Landmarks of the Innovative Development of Russia [in Russian], VIAM, Moscow (2015), 720 p.

E. N. Kablov, “Aircraft materials science: results and perspectives,” Vest. Ross. Akad. Nauk, 72(1), 3 – 12 (2002).

V. V. Gerasimov, “From single-crystal uncooled blades to turbine blades with penetrative (transpiration) cooling produced by additive technologies (a review of the processes of casting of single-crystal GTE blades),” Trudy VIAM, No. 10, Art. 01 (2016), URL: http://www.viam-works.ru (date of call 27.10.2016), DOI: https://doi.org/10.18577/2307-6046-2016-0-10-1-1.

M. A. Zlenko, A. A. Popovich, and I. N. Mutylina, Additive Technologies in Machine Building [in Russian], Izd. Politekh. Univers., St. Petersburg (2013), 222 p.

V. Sh. Sufiyarov, A. A. Popovich, E. V. Borisov, and I. A. Polozov, “Selective laser melting of refractory nickel alloy,” Tsvetn. Met., No. 1(865), 79 – 84 (2015).

I. Yadroitsev, A. Gusarov, I. Yadroitseva, and I. Smurov, “Single track formation in selective laser melting of metal powders,” J. Mater. Proc. Technol., 210, 1624 – 1631 (2010).

E. A. Lukina, M. R. Orlov, E. V. Filonova, et al., “A study of the structure and phase condition of refractory nickel alloys in the process of selective laser melting,” in: Role of Fundamental Research in Implementation of “Strategic Directions of Advancement of Materials and Processing Technologies for up to 2030, Reports of III All-Russian Scientific and Engineering Conference [in Russian], VIAM, Moscow (2016), p. 22.

I. A. Trennikov, A. A. Alekseev, D. V. Zaitsev, and E. B. Filonova, “Studies of phase and structural changes and residual stresses during high-temperature creep in alloy VZhM4,” Aviats. Mater. Tekhnol., No. 2, 11 – 19 (2011).

R. E. Shalin, I. L. Svetlov, and E. B. Kachanov, Single Crystals of Nickel Refractory Alloys [in Russian], Mashinostoenie, Moscow (1997), 336 p.

R. Honeycomb, Plastic Deformation of Metals [Russian translation], Mir, Moscow (1972), 408 p.

O. G. Osipenkova, M. R. Orlov, and V. V. Avtaev, “Anisotropy of elastoplastic characteristics of refractory nickel alloys — base for designing single-crystal turbine blades,” Deform. Razrush. Mater., No. 11, 12 – 19 (2013).

A. G. Evgenov, S. V. Nerush, and S. A. Vasilenko, “Fabrication and testing of fine metallic powder of nickel-base high-chromium alloy as applied to LMD-cladding,” Trudy VIAM, No. 5, Art. 04 (2014), URL: http://www.viam-works.ru (date of call 07.10.2016), DOI: https://doi.org/10.18577/2307-6046-2014-0-5-4-4).

A. V. Vostrikov and D. I. Sukhov, “Production of granules by the PREP method for additive technologies — current status and prospects,” Trudy VIAM, No. 8, Art. 03 (2016), URL: http://www.viam-works.ru (date of call 27.10.2016), DOI: https://doi.org/10.18577/2307-6046-2016-0-8-3-3.

S. V. Nerush and A. G. Evgenov, “A study of fine metallic powder of refractory alloy of grade EP648-VI as applied to laser LMD-cladding and assessment of the quality of cladding of nickel-base powder material on HPT rotor blades,” Trudy VIAM, No. 3, Art. 01 (2014), URL: http://www.viam-works.ru (date of call 12.07.2016), DOI: https://doi.org/10.18577/2307-6046-2014-0-3-1-1.

The study has been performed with financial support of the Russian Foundation for Basic Research (Grant No. 14-29-10246) within the framework of implementation of complex research directions 2.1 (Fundamental Oriented Research) and 10.4 (Production of Bi- and Polymetallic Naturally Reinforced Metallic Materials by the Method of Direct Laser Synthesis from Metallic Powders) (“Strategic Directions of Advancement of Materials and Processing Technologies for up to 2030”) [1].

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 2, pp. 65 – 68, February, 2019.

Rights and permissions

About this article

Cite this article

Treninkov, I.A., Filonova, E.V., Medvedev, P.N. et al. A Study of Crystallographic Texture in a Refractory Nickel Alloy After Selective Laser Melting and Heat Treatment. Met Sci Heat Treat 61, 135–140 (2019). https://doi.org/10.1007/s11041-019-00389-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-019-00389-z