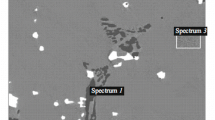

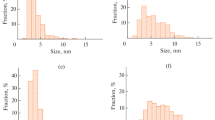

The distribution of phosphorus and sulfur impurities in the γ- and γ1-phases of single crystals of alloy ZhS36-VI is studied by high-resolution methods of transmission electron microscopy and microscopic x-ray spectrum analysis. It is shown that these impurities are mostly concentrated in the γ-solid solution, which contains local regions of their high content. The kind of the distribution of the impurities is preserved after testing for long-term strength; the nonuniformity of the distribution of sulfur between the γ- and γ1-phases becomes more manifested, especially for the composition with a high sulfur content.

Similar content being viewed by others

Notes

Here and below in the paper the contents of the elements are given in weight percent.

References

V. V. Sidorov and P. G. Min, “Refining of complexly alloyed nickel melt from sulfur impurity during melting in vacuum induction furnace. Part 1,” Élektrometallurgiya, 3, 18–23 (2014).

P. G. Min and V. V. Sidorov, “Experience of processing of casting waste of alloy ZhS32-VI at the VIAM scientific and production department for making cast bar billets,” Aviats. Mater. Tekhnol., No. 4, 20 – 25 (2013).

V. V. Sidorov, Effect of Admixtures and Surface-Active Additions on Formation of Structure and Properties of Highly Refractory Castable Alloys, Author’s Abstract of Doctoral’s Thesis [in Russian], Moscow (1989), 50 p.

M. V. Pridantsev, Effect of Impurities and Rare-Earth Elements on the Properties of Alloys [in Russian], Metallurgizdat, Moscow (1962), 208 p.

R. T. Holt and W. Wallace, “Impurities and trace elements in nickel-base superalloys,” Int. Met. Rev., 21(1), 1 – 24 (1976).

Chao Yuan and Fengshi Yin, “Effect of phosphorus on microstructure and high temperature properties of a cast Ni-base superalloy,” J. Mater. Sci. Technol., 18(6), 555 – 557 (2002).

Yaoxiao Zhu, John Radavich, Zhi Zhang, and Changxu Shi, “Development and long-time structural stability of a low segregation Hf free superalloys – DZ 125L,” in: Superalloys-2000 (2000), pp. 329 – 339.

E. N. Kablov (ed.), Cast Blades of Gas Turbine Engines [in Russian], Nauka, Moscow (2006), 632 p.

E. N. Kablov, “VIAM materials and technologies for “Aviadvigatel’,” Perm. Aviats. Dvig., No. 31, 43 – 47 (2014).

E. N. Kablov, “VIAM developments for gas turbine engines and units,” Kryl’ya Rodiny, No. 4, 31 – 33 (2010).

E. N. Kablov, N. V. Petrushin, I. L. Svetlov, and I. M. Demonis, “Castable refractory nickel alloys for advanced aircraft GTE,” Tekhnol. Legk. Splavov, No. 2, 6 – 16 (2007).

R. E. Shalin, S. T. Kishkin, E. B. Kachanov, V. V. Sidorov, et al., Single Crystal Nickel-Base Alloy, Patent 1 513 934 RF [in Russian], Patentee: All-Union Research Institute of Aviation Materials, 04.01.1988.

E. N. Kablov, “Innovative developments of FGUP “VIAM” GNTs RF on implementation of “Strategic Directions of Advancement of Materials and Processing Technologies for up to 2030,” Aviats. Mater. Tekhnol., No. 1, 3 – 33 (2015), DOI: https://doi.org/10.18577/2071-9140-2015-0-1-3-33.

P. V. Yakimovich, A. V. Alekseev, and P. G. Min, “Determination of low contents of phosphorus in refractory nickel alloys by the method of ISP-MS,” Trudy VIAM, Elektron. Zh., No. 10, Art. 02 (2014), URL: http://www.viam-works.ru (date of call 18.10.2017), DOI: https://doi.org/10.18577/2307-6046-2014-0-10-2-2.

E. A. Mekhanik, P. G. Min, N. V. Gundobin, and G. Yu. Rastegaeva, “Development of a method for determining the mass fraction of sulfur in refractory nickel alloys and steels in a concentration range from 0.0001 to 0.0009%,” Trudy VIAM, Elektron. Zh., No. 9, Art. 12 (2014), URL: http://www.viam-works.ru (date of call 18.10.2017), DOI: https://doi.org/10.18577/2307-6046-2014-0-9-12-12.

The work has been performed within the framework of implementation of scientific direction 10.1 (Resource Saving Processes of Melting of Advanced Castable and Deformable Super-Refractory Alloys with Allowance for Processing All Kinds of Waste) (“Strategic Directions of Advancement of Materials and Processing Technologies for up to 2030”) [13].

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 2, pp. 61 – 65, February, 2019.

Rights and permissions

About this article

Cite this article

Sidorov, V.V., Min, P.G., Vadeev, V.E. et al. A Study of Sulfur and Phosphorus Distribution in a Single Crystal of Refractory Alloy by Transmission Electron Microscopy and MXRSA. Met Sci Heat Treat 61, 130–134 (2019). https://doi.org/10.1007/s11041-019-00388-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-019-00388-0