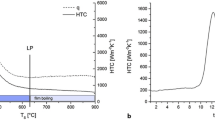

Temperature distribution in a 42CrMo4 steel test piece during local cooling from 900°C with a water jet from an injector is studied. Heat flux distribution with action of a jet on the side surface of a test piece is analyzed. The hardness of a test piece side surface is measured and the microstructure of its different cross sections is studied. Numerical software is used in order to describe cooling kinetics for the side surface of a cylindrical test piece by a fine water jet. Operating parameters are optimized for cooling by analyzing the effect on them of the number of injectors and their arrangement. Conditions are revealed for improving cooling efficiency for cylindrical test pieces with injectors.

Similar content being viewed by others

References

I. Suárez, M. M. Prieto, E. Muelas, and L. Loredo, “Study on the influence of water jet array cooling systems on the thermal state of steel transfer bars during the rolling process,” in: 5th European Thermal-Sciences Conference. The Netherlands, May (2008).

Y. Mitsutake and M. Monde, “Heat transfer during transient cooling of high temperature surface with an impinging jet,” Heat Mass Transfer, 37(4 – 5), 321 – 328 (2001).

Kokado, J. I. Hatta , N. Takuda, et al., “An analysis of film boiling phenomena of subcooled water spreading radially on a hot steel plate,” Arch. Eisenhüttenwes, 55(3), 113 – 118 (1984).

M. P. Arbuzov and Yu. E. Bushuev, “Decomposition of martensite and formation of carbide phases during tempering of chromium steels,” Met. Sci. Heat Treat., 13(1), 10 – 13 (1971).

N. V. Zimin, “The effectiveness of intense spray quenching,” Met. Sci. Heat Treat., 12(5), 381 – 384 (1970).

XiaoMin Cheng, Lin Zhou, Rufu Hu, et al., “Simulation for water jet incremental sheet metal forming,” in: Second International Conference on Computer Modelling and Simulation (2010), pp. 362 – 366.

Jinxu Li, Takahito Ohmura, and Kaneaki Tsuzaki, “Microstructure effect on nanohardness distribution for medium-carbon martensitic steel,” Sci. China, Ser. E: Technol. Sci., 49(1), 10 – 19 (2006).

C. Motzkus, E. Gehin, and F. Gensdarmes, “Etude de la mise en suspension de microgouttelettes lors de l’impact d’une goutte sur une surface sèche ou sur un film liquide,” in: 21ème Congrès Français sur les Aérosols, Paris (2005), pp. 101 – 106.

Stainless Steel: Tables of Technical Properties. The European Stainless Steel Development Association Materials and Applications Series, EuroInox (2007), Vol. 5.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 5, pp. 32 – 37, May, 2011.

Rights and permissions

About this article

Cite this article

Naceur, I.B., Kchaou, M. & Ksibi, H. Optimization of local cooling for hot components by a water jet. Met Sci Heat Treat 53, 233–238 (2011). https://doi.org/10.1007/s11041-011-9375-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-011-9375-1