A representative volume element (RVE) with 11 uniform fiber packings is studied. The effective modulus of RVE corresponding to the different packing types is evaluated using the finite-element modelling and a semianalytical multistep rule of mixtures. The equivalent modulus of the RVE depends on the packing type. The elongated triangular packing type was closest to the random packing type. All the packing types displayed a strong transverse isotropy with less than a 1% variation in equivalent modulus in the two transverse directions. The multistep rule of mixtures could allow for changes in the moduli due to the different packing types. However, this method consistently underpredicted the equivalent modulus compared with full FE results. The effective modulus for the random packing closest to that of the elongated triangular packing type. The stress distribution in the interface varied strongly with packing type and loading direction. The sparsest packing type, i.e., the truncated hexagonal one led to both the highest equivalent modulus and the highest stress concentrations in the interface. The densest packing type, i.e., the triangular packing, led to the lowest modulus and lowest radial stress concentrations.

Similar content being viewed by others

References

B. D. Agarwal, L. J. Broutman, and K. Chandrashekhara, Analysis and Performance of Fiber Composites, John Wiley & Sons (2006).

E. K. Gamstedt and B. A. Sjögren, “Micromechanisms in tension-compression fatigue of composite laminates containing transverse plies.” Composites Science and Technology. 59, No. 2, 167-178 (1999).

H. M. Sertse et al., “Challenge problems for the benchmarking of micromechanics analysis: Level I initial results,” Journal of Composite Materials, 52, No. 1, 61-80 (2017).

M. G. Knight, L. C. Wrobel, and J. L. Henshall, “Micromechanical response of fibre-reinforced materials using the boundary element technique,” Composite Structures, 62, 341-352 (2003).

B. Sabuncuoglu et al., “Micro-scale finite element analysis of stress concentrations in steel fiber composites under transverse loading,” Journal of Composite Materials, 49, 1057-1069 (2014).

A. R. Maligno, N. A. Warrior, and A. C. Long, “Finite element investigations on the microstructure of fibre-reinforced composites,” Express Polymer Letters, 2, 665-676 (2008).

S. Malekmohammadi, Efficient Multi-Scale Modelling of Viscoelastic Composites with Different Microstructures, University of British Columbia (2014).

S. Kari et al., “Computational evaluation of effective material properties of composites reinforced by randomly distributed spherical particles,” Composite Structures, 77, 223-231 (2007).

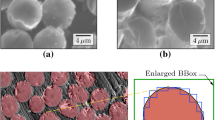

M. V. Pathan et al., “A new algorithm to generate representative volume elements of composites with cylindrical or spherical fillers,” Composites, Part B, 110, 267-278 (2017).

X. Wang et al., “A long-range force based random method for generating anisotropic 2D fiber arrangement statistically equivalent to real composites,” Composites Science and Technology, 180, 33-43 (2019).

A. A. Gusev, P. J. Hine, and I. M. Ward, “Fiber packing and elastic properties of a transversely random unidirectional glass/epoxy composite,” Composites Science and Technology, 60, No. 4, 535-541 (2000).

A. Wongsto and S. Li, “Micromechanical FE analysis of UD fibre-reinforced composites with fibres distributed at random over the transverse cross-section,” Composites, Part A, 36, No. 9, 1246-1266 (2005).

A. Heppes, “Some densest two-size disc packings in the plane,” Discrete & Computational Geometry, 30, No. 2, 241-262 (2003).

Circle packing. A: Wikipedia, DOI https://en.wikipedia.org/wiki/Circle_packing

S. Choi and W. Ji, “Effects of fiber arrangements on stress distributions over the transverse cross section of unidirectionally continuous fiber-reinforced composites,” Composites Research. The Korean Society for Composite Materials, 33, No. 1, 30-37 (2020).

M. Hojo et al., “Effect of fiber array irregularities on microscopic interfacial normal stress states of transversely loaded UD-CFRP from viewpoint of failure initiation,” Composites Science and Technology, 69, No. 11, 1726-1734 (2009).

M. K. Hassanzadeh-Aghdam and R. Ansari, “Role of fiber arrangement in the thermal expanding behavior of unidirectional metal matrix composites,” Materials Chemistry and Physics, 252, 123273 (2020).

L. Zhang, L. J. Ernst, and H. R. Brouwer, “Transverse behaviour of a unidirectional composite (glass fibre reinforced unsaturated polyester). Part I. Influence of fibre packing geometry,” Mechanics of Materials, 27, No. 1, 13-36 (1998).

A. R. Maligno, N. A. Warrior, and A. C. Long, “Effects of inter-fibre spacing on damage evolution in unidirectional (UD) fibre-reinforced composites,”. European Journal of Mechanics-A/Solids, 28, No. 4, 768-776, (2009).

R. J. D’Mello and A. M. Waas, “Influence of unit cell size and fiber packing on the transverse tensile response of fiber reinforced composites,” Materials. Multidisciplinary Digital Publishing Institute, 12, No. 16, 2565 (2019).

J. N. Goodier, “Concentration of stress around spherical and cylindrical inclusions and flaws,” TASME, 55, 39 (1933).

C. Heinrich et al., “The influence of the representative volume element (RVE) size on the homogenized response of cured fiber composites,” Modelling and Simulation in Materials Science and Engineering. IOP Publishing, 20, No. 7, 75007 (2012).

B. Sabuncuoglu, L. Gorbatikh, and S. V. Lomov, “Analysis of stress concentrations in transversely loaded steel-fiber composites with nano-reinforced interphases,” International Journal of Solids and Structures, 130, 248-257 (2018).

A. R. Melro, P. P. Camanho, and S. T. Pinho, “Generation of random distribution of fibres in long-fibre reinforced composites,” Composites Science and Technology, 68, No. 9, 2092-2102 (2008).

Z. Hashin, “Analysis of composite materials — a survey,” Journal of Applied Mechanics, 451-505 (1983).

J. C. Halpin and J. L. Kardos, “The Halpin–Tsai equations: a review,” Polymer Engineering & Science, 16, No. 5, 344-352 (1976).

C. L. I. Tucker and E. Liang, “Stiffness predictions for unidirectional short-fiber composites: Review and evaluation,” Composites Science and Technology, 59, No. 5, 655-671 (1999).

C. C. Chamis, “Mechanics of composite materials: past, present, and future,” J. Compos. Technol. and Research, 11, No. 1, 3-14 (1989).

T. Mori and K. Tanaka, “Average stress in matrix and average elastic energy of materials with misfitting inclusions,” Acta Metall., 21, No. 5, 571-571 (1973).

A. Jain, “Micro and mesomechanics of fibre reinforced composites using mean field homogenization formulations: A review,” Materials Today Communications, 21, No. 1, 100552 (2019).

S. Koley, P. M. Mohite, and C. S. Upadhyay, “A micromechanical study and uncertainty quantification for effective properties of unidirectional fibre reinforced composites,” Composite Structures, 225, 111141(2019).

B. Sabuncuoglu et al., “Micro-scale finite element analysis of stress concentrations in steel fiber composites under transverse loading,” Journal of Composite Materials, 49, No. 9, 1057-1069 (2015).

B. Sabuncuoglu, O. Cakmakci, and F. S. Kadioglu, “Fiber/matrix interface stress analysis of flax-fiber composites under transverse loading considering material nonlinearity,” Journal of Reinforced Plastics and Composites, 39, Nos. 9-10, 345-360 (2020).

H. Miyagawa et al., “Transverse elastic modulus of carbon fibers measured by Raman spectroscopy,” Materials Science and Engineering, 412, No. 1, 88-92 (2005).

Campus Plastics, 2020. www.campusplastics.com.

D. P. Mitchell, “Spectrally optimal sampling for distribution ray tracing,” Proceedings of the 18th Annual Conference on Computer Graphics and Interactive Techniques, 157-164 (1991).

T. Kanit et al., “Determination of the size of the representative volume element for random composites: statistical and numerical approach,” International Journal of Solids and Structures, 40, Nos. 13-14, 3647-3679 (2003).

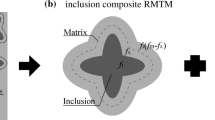

A. Jain et al., “Pseudo-grain discretization and full Mori Tanaka formulation for random heterogeneous media: Predictive abilities for stresses in individual inclusions and the matrix,” Composites Science and Technology, 87, 86-93 (2013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Russian translation published in Mekhanika Kompozitnykh Materialov, Vol. 58, No. 6, pp. 1263-1280, November-December, 2022. Russian DOI: https://doi.org/10.22364/mkm.58.6.10.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Simon, J., Jain, A. The Effect of Packing Type on the Equivalent Modulus and Stress Concentrations of Unidirectional Composites. Mech Compos Mater 58, 883–896 (2023). https://doi.org/10.1007/s11029-023-10076-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11029-023-10076-z