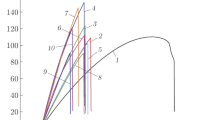

The mechanical characteristics of a number of antifriction polymer materials at room temperature were studied to analyze their operability in the bearings of support parts with a ball segment. According to the unified technology of dry mixing, pressing and free sintering, six tablets-samples were prepared for each of the 19 types of compositions of fluoroplast powders and various fillers with a dispersion from units to tens of micrometers (coke, bronze, carbon fiber, colloidal and thermally expanded graphite, molybdenum disulfide and their combinations). For all materials, the Brinell hardness, the proportions of strains with different rheology in the total deformation, Young’s modulus, and stresses in free compression corresponding to the strains of 1, 5, and 10%, stiffness in constrained compression, corresponding to stresses of 50, 100, and 150 MPa, and their dependence on the presence of a hole (empty or filled with grease) were determined. All tests were performed according to a multistage program with loading and unloading cycles, relaxation, and rest periods. The data obtained, together with tribological characteristics (will be published in the second part), can serve as the basis for the selection of antifriction materials, their composition, and manufacturing technologies for bridge support units.

Similar content being viewed by others

References

A. Azizinamini, E. H. Power, G. F. Myers, and H. Ozyildirim Celik, Bridges for Service Life Beyond 100 Years: Innovative Systems, Subsystems and Components, Washington, The National Academies Press (2014).

Pat. EN 146859 U1. The bearing part of a bridge / V. V. Bukanov, A. S. Ipanov, S. A. Khatipov, A. A. Adamov, and S. G. Ostrer — Declared 24.04.2014 // — Bull. No. 29 (2014).

Technical requirements for bearing parts with a spherical segment and antifriction coating / Introduced by an order of Russian Railways OJSC No. 2755r dated December 12, (2013). URL: http://scbist.com/scb/uploaded/docs/2013/dekabr-2013/5040-rasporyazhenie-oao-rzhd-ot-12-12-2013-n-2755r.htm (Date of access: 06.12.2021)

EAD 050009-00-0301 Spherical and cylindrical bearing with special sliding material made of UHMWPE (Ultra-highmolecular weight polyethylene) / EOTA, (2018). URL: https://www.eota.eu/download?file=/2014/14-05-0004/ead%20for%20ojeu/ead%20050004-00-0301_ojeu2018.pdf (accessed 06.12.2021)

EAD 050009-00-0301 Spherical and cylindrical bearing with special sliding material made of fluoropolymer / EOTA, (2017). URL: https://www.eota.eu/download?file=/2015/15-05-0009/ead%20for%20ojeu/ead%20050009-00-0301_ojeu2017.pdf (accessed 06.12.2021)

T. I. Campbell, W. L. Kong, and D. G. Manning, “Laboratory investigation of the coefficient of friction in the polytetrafluoroethylene slide surface of a bridge bearing,” Transportation Research Record, 1275, 45-52 (1987).

J. F. Stanton, C. W. Roeder, and T. I. Campbell, Appendix C: Friction and wear of PTFE sliding surfaces / In NCHRP Report 432: High-Load Multi-Rotational Bridge Bearings, TRB, National Research Council, Washington, D.C. (1999).

L. Bocklenberg, K. Winkler, P. Mark, and S. Rybarz, “Low friction sliding planes of greased PTFE for high contact pressures,” Open J. Civil Eng., 6, 105-116 (2016).

A. A. Adamov, “Experimental support and identification of a model for an isotropic body with an elastic volumetric compressibility of particulate-filled composites based on fluoroplast and ultra-high molecular weight polyethylene, Konstruktsii iz Kompozit. Materialov, No. 2, 28-37 (2013).

A. A. Adamov, “Experimental study of the mechanical behavior and friction of polymeric antifriction materials at pressures up to 60 MPa,” Proc. XI All-Russian Congress on Fundamental Problems of Theory and Appl. Mechanics, Kazan, 20-24 August, 79-81 (2015).

Pat. EN 2692130 C2. Reversible friction test facility / A. S. Ipanov, A. A. Adamov, A. V. Svetlakov, V. D. Vasilenko, I. M. Patrakov, and I. V. Nepein— Declared 24.10.2017 // Bull. No. 18 (2019).

N. P. Istomin and A. P. Semenov, Antifriction Properties of Composite Materials based on Fluoropolymers [in Russian], M., Nauka (1981).

A. K. Pugachev and O. A. Roslyakov, Processing of Fluoroplastics into Products [in Russian], L., Khimiya (1987).

S. G. Ostrer, Fluoropolymers in the Chemical Industry [in Russian], Perm, (2019).

B. Bhushan and D. F. Wilcoc, “Wear behavior of polymer compositions in dry reciprocating sliding,” Wear, 75, 41-70 (1982).

S. Bahadur and D. Tabor, “The wear of filled polytetrafluoroethylene,” Wear, 98, 1-13 (1984).

J. Plitmanis, K. I. Cirule, A. F. Kregers, A. E. Terauds, and A. M. Tolks, “Optimization of the composition and tribological properties of high-density polyethylene-calcite-silicon nitride composites by the method of experiment planning,” Mech. Compos. Mater., 32, No. 5, 483-486 (1996).

Yu. K. Mashkov et al., Composite Materials based on Polytetrafluoroethylene. Structural Modification [in Russian], M., Mashinostroenie (2005).

B. A. Lyukshin et al., Dispersedly-Filled Polymer Composites for Technical and Medical Purposes [in Russian] / Ed. A. V. Gerasimov, Novosibirsk, Publishing House of the Siberian Branch of the Russian Academy of Sciences (2017).

T. L. Schmitz, J. E. Action, D. L. Burris, J. C. Ziegert, and W. G. Sawyer, “Wear-rate uncertainty analysis,” Transactions ASME, J. Tribology, 126, 802-808 (2004).

D. L. Burris and W. G. Sawyer, “A low friction and ultra low wear rate PEEK/PTFE composite,” Wear, 261, 410-418 (2006).

W. G. Sawyer, K. D. Freudenberg, P. Bhimaraj, and L. S. Schadler, “A study on the friction and wear behavior of PTFE filled with alumina nanoparticles,” Wear, 254, 573-580 (2003).

W. Xu, H. Gao, L.-L. Gao, X. Chen, and Y. Wang, “Tensile ratcheting behaviors of bronze powder filled polytetrafluoroethylene,” Front. Chem. Sci. Eng., 7, 103-109 (2013).

S. Kolhe, A. Deshpande, and K. Wangikar, “Wear behavior of polytetrafluoroethylene composites: A review,” In: (eds) Smart Technologies for Energy, Environment and Sustainable Development. Lecture Notes on Multidisciplinary Industrial Engineering /Eds. M. Kolhe, P. Labhasetwar, and H. Suryawanshi, Singapore, Springer (2019).

F. Stan and C. Fetecau, “Study of stress relaxation in polytetrafluoroethylene composites by cylindrical macroindentation,” Composites, B47, 298-307 (2013).

H. Cheng, and X. Cheng, “Mechanical and tribological behavior of polytetrafluoroethylene composites reinforced by carbon nanotubes and poly-P-oxybenzoate,” High Performance Polym., 25, 611-621 (2013).

L. F. Tóth, P. De Baets, and G. Szebényi, “Thermal, viscoelastic, mechanical and wear behavior of nanoparticle filled polytetrafluoroethylene: A comparison,” Polymers, 12, No. 9, 1940 (2020).

A. A. Okhlopkova and E. Y. Shits, “Structure and properties of Teflon composites with natural diamond powders,” Mech. Compos. Mater., 40, No. 2, 145-150 (2004).

A. A. Okhlopkova, P. N. Petrova, S. N. Popov, and S. A. Sleptsova, “Tribotechnical polymer composite materials based on polytetrafluoroethylene,” Russian J. General Chemistry, 52, No. 3, 147-152 (2008).

A. A. Okhlopkova, S. A. Sleptsova, A. G. Parnikova, T. M. Ulyanova, and O. Yu. Kalmychkova, “Tribological and physical-mechanical properties of nanocomposites based on PTFE and aluminum oxide,” Friction and Wear, 29, No. 6, 635-639 (2008).

A. P. Vasilev, T. S. Struchkova, L. A. Nikiforov, A. A. Okhlopkova, J. H. Cho, P. N. Grakovich, and E. L. Shim, “Mechanical and tribological properties of polytetrafluoroethylene composites with carbon fiber and layered silicate fillers,” Molecules, 24, No. 2, 224 (2019).

V. A. Shelestova, V. V. Serafimovich, and P. N. Grakovich, “The effect of the size of carbon fibers on the physicomechanical properties of fulvic composites,” Mech. Compos. Mater., 38, No.2, 125-130 (2002).

O. V. Kropotin, Yu. K. Machkov, and O. A. Kurguzova, “Creation of a polymeric antifriction nanocomposite based on polytetrafluoroethylene with an increased wear resistance,” Omsk Scientific. Vestnik, 120, No. 2, 86-90 (2013).

E. M. Konova, S. G. Ostrer, and S. A. Khatipov, “Influence of the nature of the filler on the physical and mechanical properties of radiation modifications of composites based on polytetrafluoroethylene,” Plast. Massy, No. 5, 40-43 (2011).

GOST 4670-2015 (ISO 2039-1:2001). Plastics. Determination of hardness. Ball push method, Standartinform, Moscow (2016).

GOST 4651-2014 (ISO 604:2002). Plastics. Compression test method, M., Standartinform (2014).

A. Ya. Goldman, Volumetric Deformation of Plastics [in Russian], L., Mashinostroenie (1984).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Mekhanika Kompozitnykh Materialov, Vol. 58, No. 5, pp. 965-986, September-October, 2022. Russian DOI: https://doi.org/10.22364/mkm.58.5.06.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Adamov, A.A., Keller, I.E., Ostrer, S.G. et al. Evaluation of the Performance of Antifriction PTFE Composites at a Pressure Over 60 MPA. I. Comparison of Their Hardness and Deformation Properties Under Free and Constrained Compression. Mech Compos Mater 58, 673–688 (2022). https://doi.org/10.1007/s11029-022-10058-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11029-022-10058-7