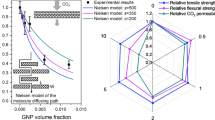

Matrix microcracking is considered the main factor responsible for the gas permeation in linerless pressure vessels and storage tanks. The addition of halloysite nanotubes (HNTs) to them at different concentrations was studied in order to enhance their microcrack resistance. A 50% increase in the cracking onset stress was found at a 5% addition of HNTs to the epoxy matrix. Moreover, a 60% increase was observed at a similar level of microcrack density compared with that of neat epoxy. A reactive diluent was used as an alternative to keep the viscosity suitable for the filament winding process and to offset the rise in viscosity by HNT incorporation. Despite the fact that the matrix fracture toughness increased even to 10% of HNTs, no growth in the microcrack resistance was found at more than 5% of HNTs. As a result, it was concluded that the microcracking phenomenon can be affected not only by the matrix fracture toughness, but also by the residual thermal stresses.

Similar content being viewed by others

References

R. Talreja, S. Yalvac, L. D. Yats, and D. G. Wetters, “Transverse cracking and stiffness reduction in cross ply laminates of different matrix toughness,” J. Compos. Mater., 26, No. 11, 1644-1663 (1992).

J. A. Nairn, in: R. Talreja, J-A Manson (eds.), Polymer Matrix Composites, Ch. 13, Elsevier Science (2001).

J. A. Nairn and S. Hu, “The formation and effect of outer-ply microcracks in cross-ply laminates: A variational approach,” Eng. Fract. Mech., 41, No. 2, 203-221 (1992).

J. F. Timmerman, M. S. Tillman, B. S. Hayes, and J. C. Seferis, “Matrix and fiber influences on the cryogenic microcracking of carbon fiber/epoxy composites,” Compos. Part A, Appl. Sci. Manuf., 33, 323-329 (2002).

K. Mallick, J. Cronin, K. Ryan, S. Arzberger, and N. Munshi, “An integrated systematic approach to linerless composite tank development in 46th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics & Materials Conference. Austin, Texas. United States (2005).

A. J. Kinloch, S. J. Shaw, and D. L. Hunston, “Deformation and fracture behaviour of a rubber-toughened epoxy: 2. Failure criteria,” Polymer (Guildf), 24, No. 10, 1355-1363 (1983).

R. Bagheri, B. T. Marouf, and R. A. Pearson, “Rubber-toughened epoxies: A critical review,” Polym. Rev., 49, No. 3, 201-225 (2009).

M. R. Ricciardi, I. Papa, A. Langella, T. Langella, V. Lopresto, and V. Antonucci, “Mechanical properties of glass fibre composites based on nitrile rubber toughened modified epoxy resin,” Compos. Part B Eng., 139, 259-267 (2018).

M. Agarwal, M. Arif, A. Bisht, V. K. Singh, and S. Biswas, “Investigation of toughening behavior of epoxy resin by reinforcement of depolymerized latex rubber,” Sci. Eng. Compos. Mater., 22, No. 4, 399-404 (2015).

F. Ghadami, M. R. Dadfar, and M. Kazazi, “Hot-cured epoxy-nanoparticulate-filled nanocomposites: Fracture toughness behavior,” Eng. Fract. Mech., 162, 193-200 (2016).

B. C. Kim, S. W. Park, and D. G. Lee, “Fracture toughness of the nano-particle reinforced epoxy composite,” Compos. Struct., 86, 1-3, 69-77 (2008).

J. Cho, I. M. Daniel, and D. A. Dikin, “Effects of block copolymer dispersant and nanotube length on reinforcement of carbon/epoxy composites,” Compos. Part A, Appl. Sci. Manuf., 39, No. 12, 1844-1850 (2008).

G. Gkikas, N. M. Barkoula, and A. S. Paipetis, “Effect of dispersion conditions on the thermo-mechanical and toughness properties of multi walled carbon nanotubes-reinforced epoxy,” Compos. Part B, Eng., 43, No. 16, 2697-2705 (2012).

D. Quan, J. L. Urdániz, and A. Ivanković, “Enhancing mode-I and mode-II fracture toughness of epoxy and carbon fibre reinforced epoxy composites using multi-walled carbon nanotubes,” Mater. Des., 143, 81-92 (2018).

Y. C. Shin, W. Il Lee, and H. S. Kim, “Mode II interlaminar fracture toughness of carbon nanotubes/epoxy film-interleaved carbon fiber composites,” Compos. Struct., 236, 111808, (2020)

T. S. Gaaz, E. K. Hussein, K. A. Subhi, and A. Al-Amiery, “Mechanical and morphology properties of titanium oxideepoxy nanocomposites,” Int. J. Low-Carbon Technol., 16, No. 1, 240-245 (2020).

M. Du, B. Guo, and D. Jia, “Newly emerging applications of halloysite nanotubes: a review,” Polym Int, 59, 574-582 (2010).

M. Liu, Z. Jia, D. Jia, and C. Zhou, “Recent advance in research on halloysite nanotubes-polymer nanocomposite,” Progress in Polymer Science, 39, No. 8, 1498-1525, (2014).

C. I. Idumah, A. Hassan, J. Ogbu, J. Ndem, and I. C. Nwuzor, “Recently emerging advancements in halloysite nanotubes polymer nanocomposites,” Compos. Interfaces, 1-74 (2018)

C. Li, J. Liu, X. Qu, B. Guo, and Z. Yang, “Polymer-modified halloysite composite nanotubes,” Polym. Sci., 110, No. 6, 3638-3646 (2008)

Y. Ye, H. Chen, J. Wu, and L. Ye, “High impact strength epoxy nanocomposites with natural nanotubes,” Polymer (Guildf)., 48, No. 21, 6426-6433 (2007).

T. S. Gaaz, A. B. Sulong, M. N. M. Ansari, A. A. H. Kadhum, A. A. Al-Amiery, and M. S. H. Al-Furjan, “Effect of halloysite nanotubes loading on thermo-mechanical and morphological properties of polyurethane nanocomposites,” Mater. Technol., 32, No. 7, 430-442 (2016).

V. Vahedi, P. Pasbakhsh, and S. P. Chai, “Toward high performance epoxy/halloysite nanocomposites: New insights based on rheological, curing, and impact properties,” Mater. Des., 68, 42-53 (2015).

Y. Tang, L. Ye, S. Deng, C. Yang, and W. Yuan, “Influences of processing methods and chemical treatments on fracture toughness of halloysite-epoxy composites,” Mater. Des., 42, 471-477 (2012).

S. Deng, J. Zhang, L. Ye, and J. Wu, “Toughening epoxies with halloysite nanotubes,” Polymer (Guildf)., 49, No. 23, 5119-5127 (2008).

T. Yokozeki, Y. Iwahori, and S. Ishiwata, “Matrix cracking behaviors in carbon fiber/epoxy laminates filled with cupstacked carbon nanotubes (CSCNTs),” Compos. Part A, Appl. Sci. Manuf., 38, No. 3, 917-924 (2007).

M. Bashar, U. Sundararaj, and P. Mertiny, “Study of matrix micro-cracking in nano clay and acrylic tri-block-copolymer modified epoxy/basalt fiber-reinforced pressure-retaining structures,” Express Polym. Lett., 5, No. 10, 882-896 (2011).

E. S. Rodríguez, V. G. Falchi, L. Asaro, I. A. Zucchi, and R. J. J. Williams, “Toughening an epoxy network by the addition of an acrylic triblock copolymer and halloysite nanotubes,” Compos. Commun., 12, 86-90 (2019).

D. V. A. Ceretti, L. C. E. da Silva, M. do Carmo, Goncalves, and D. J. Carastan, “The role of dispersion technique and type of clay on the mechanical properties of clay/epoxy composites,” Macromol. Symp., 383, 1800055, 1-10 (2019).

R. Rong, X. Xu, S. Zhu, B. Li, X. Wang, and K. Tang, “Facile preparation of homogeneous and length controllable halloysite nanotubes by ultrasonic scission and uniform viscosity centrifugation,” Chem. Eng. J., 291, 20-29 (2016).

K. Mallick, “Ultralight linerless composite tanks for in-space applications in Space,” 2004 Conference and Exhibit AIAA 2004-5801. San Diego, California, United State (2004).

J. Varna and L. Asp, “Microdamage in composite laminates: Experiments and observation,” Appl. Mech. Mater., 518, 84-89 (2014).

Y. Ye, H. Chen, J. Wu, and C. M. Chan, “Evaluation on the thermal and mechanical properties of HNT-toughened epoxy/carbon fibre composites,” Compos. Part B Eng., 42, No. 8, 2145-2150 (2011).

Y. Ye, H. Chen, J. Wu, and C. M. Chan, “Interlaminar properties of carbon fiber composites with halloysite nanotubetoughened epoxy matrix,” Compos. Sci. Technol., 71, No. 5, 717-723, (2011).

M. il Kim, S. Kim, T. Kim, D. K. Lee, B. Seo, and C. S. Lim, “Mechanical and thermal properties of epoxy composites containing zirconium oxide impregnated halloysite nanotubes,” Coatings, 7, No. 12 (2017).

Z. Li, L. Liu, A. J. Gonzalez, and D.-Y. Wang, “Bioinspired polydopamineinduced assembly of ultrafine Fe(OH)3 nanoparticles on halloysite toward highly efficient fire retardancy of epoxy resin via an action of interfacial catalysis,” Polym. Chem., 8, No. 26, 3926-3936, (2017).

Y. Tang, S. Deng, L. Ye, C. Chang, Q. Yuan, J. Zhang, and C. Zhao, “Effects of unfolded and intercalated halloysites on mechanical properties of halloysite-epoxy nanocomposites,” Compos. Part A Appl. Sci. Manuf., 42, No. 4, 345-354 (2011).

J. Zhang, D. Zhang, A. Zhang, Z. Jia, and D. Jia, “Dendritic polyamidoaminegrafted halloysite nanotubes for fabricating toughened epoxy composites,” Iran. Polym. J., 22, No. 7, 501-510 (2013).

P. Sun, G. Liu, D. Lv, X. Dong, J. Wu, and D. Wang, “Simultaneous improvement in strength, toughness, and thermal stability of epoxy/halloysite nanotubes composites by interfacial modification,” J. Appl. Polym. Sci., 133, No. 13 (2016).

P. Vijayan, A. Tanvir, M. Mrlik, M. Urbanek, and M. Al-Maadeed, “TiO2/Halloysite hybrid filler reinforced epoxy nanocomposites,” Polym. Compos., 39, S4 (2018).

S. Zeng, C. Reyes, P. A. Rodgers, S. H. Wentworth, and L. Sun, “Facile hydroxylation of halloysite nanotubes for epoxy nanocomposite applications,” Polym. (United Kingdom), 55, No. 25, 6519-6528 (2014).

M. Sánchez, J. F. Uicich, G. F. Arenas, E. S. Rodríguez, P. E. Montemartini, and M. E. Penoff, “Chemical reactions affecting halloysite dispersion in epoxy nanocomposites,” J. Appl. Polym. Sci., 136, No. 38, 1-12 (2019).

J. Hornak, P. Kadlec, and R. Polanský, “Halloysite nanotubes as an additive to ensure enhanced characteristics of coldcuring epoxy resins under fire conditions,” Polymers (Basel)., 12, No. 9, 1881 (2020).

T. V. Brantseva, S. O. Ilyin, I. Y. Gorbunova, S. V. Antonov, Y. M. Korolev, and M. L. Kerber, “Epoxy reinforcement with silicate particles: Rheological and adhesive properties - Part II: Characterization of composites with halloysite,” Int. J. Adhes. Adhes., 68, 248-255 (2016).

M. Khalina, M. H. Beheshty, and A. Salimi, “The effect of reactive diluent on mechanical properties and microstructure of epoxy resins,” Polym. Bull., 76, No. 8, 3905-3927 (2019).

M. S. Z. Abidin, T. Herceg, E. S. Greenhalgh, M. Shaffer, and A. Bismarck, “Enhanced fracture toughness of hierarchical carbon nanotube reinforced carbon fibre epoxy composites with engineered matrix microstructure,” Compos. Sci. Technol., 170, 85-92 (2019).

P. Cai, H. Zhang, D.-L. Zhao, and Z.-M. Shen, “Effect of diluent on mechanical properties of DDM/E-51 epoxy resin system,” Polym. Mater. Sci. Eng., 26, 75-77+82 (2010).

L. Kregl, G. M. Wallner, R. W. Lang, and G. Mayrhofer, “Effect of resin modifiers on the structural properties of epoxy resins,” J. Appl. Polym. Sci., 134, No. 44, 1-11 (2017).

A. Sinha, N. I. Khan, S. Das, J. Zhang, and S. Halder, “Effect of reactive and non-reactive diluents on thermal and mechanical properties of epoxy resin,” High Perform. Polym., 30, No. 10, 1159-1168 (2018).

G. Ravichandran, G. Rathnakar, N. Santhosh, R. Chennakeshava, and M. A. Hashmi, “Enhancement of mechanical properties of epoxy/halloysite nanotube (HNT) nanocomposites”, SN Appl. Sci., 1 (4), 296 (2019).

T. S. Gaaz, A. B. Sulong, A. A. H. Kadhum, A. A. Al-Amiery, M. H. Nassir, and A. H. Jaaz, “The impact of halloysite on the thermo-mechanical properties of polymer composites,” Molecules, 22, No. 5, 13-15 (2017).

M. J. Saif , M. Asif, M. Naveed, K. Zia, W. Zaman, M. Khosa, and M. Jamal, “Halloysite reinforced epoxy composites with improved mechanical properties”, Polish J. Chem. Technol., 18, No. 1, 133-135 (2016).

V. Vahedi and P. Pasbakhsh, “Instrumented impact properties and fracture behaviour of epoxy/modified halloysite nanocomposites,” Polym. Test., 39, 101-114 (2014).

M. S. Saharudin, R. Atif, S. Hasbi, M. N. A. Nazri, N. U. Saidin, and Y. Abdullah, “Synergistic effects of halloysite and carbon nanotubes (HNTs + CNTs) on the mechanical properties of epoxy nanocomposites,” AIMS Mater. Sci., 6, No. 6, 900-910 (2019).

Y. He, Q. Chen, S. Yang, C. Lu, M. Feng Y. Jiang, G. Cao, J. Zhang, and C. Liu, “Micro-crack behavior of carbon fiber reinforced Fe3O4/graphene oxide modified epoxy composites for cryogenic application,” Compos. Part A Appl. Sci. Manuf., 108, 12-22 (2018).

Z. Hashin, “Finite thermoelastic fracture criterion with application to laminate cracking analysis,” J. Mech. Phys. Solids, 44, No. 7, 1129-1145 (1996).

M. W. Joosten, S. Agius, T. Hilditch, and C. Wang, “Effect of residual stress on the matrix fatigue cracking of rapidly cured epoxy/anhydride composites,” Compos. Part A, Appl. Sci. Manuf., 101, 521-528 (2017).

L. A. Neely, V. Kochergin, E. M. See, H. D. Robinson, “Negative thermal expansion in a zirconium tungstate/epoxy composite at low temperatures,” J Mater Sci., 49, 392-396 (2014).

K. Takenaka, “Progress of research in negative thermal expansion materials: paradigm shift in the control of thermal expansion,” Front Chem, 6, 267 (2018).

J. Parameswaranpillai, A. George, J. Pionteck, and S. Thomas, “Investigation of cure reaction, rheology, volume shrinkage and thermomechanical properties of nano-TiO2 Filled Epoxy/DDS Composites,” Journal of Polymers, 2013, 183463 (2013).

Acknowledgement

The authors acknowledge the financial support of the University of Mar del Plata, the National Research Council (CONICET) and of the Agency for the Promotion of Science and Technology [FONARSEC - ANPCyT; PICT-2016-4048].

Author information

Authors and Affiliations

Corresponding author

Additional information

Russian translation published in Mekhanika Kompozitnykh Materialov, Vol. 58, No. 2, pp. 411-428, March-April, 2022. Russian DOI: https://doi.org/10.22364/mkm.58.2.11.

Rights and permissions

About this article

Cite this article

Churruca, M.J., Morán, J.I. & Rodríguez, E.S. Effect of Halloysite Nanotubes on Matrix Microcracking in Carbon Fiber/Epoxy Composites. Mech Compos Mater 58, 293–304 (2022). https://doi.org/10.1007/s11029-022-10030-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11029-022-10030-5