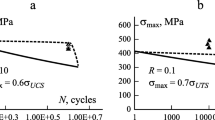

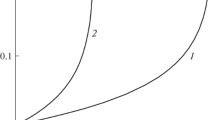

In this paper, the questions concerning the investigation of fatigue characteristics of composite materials are discussed and the changes in their static deformation and strength properties caused by preliminary cyclic actions are estimated. The aim of the work was to obtain new experimental data on damage accumulation processes in GFRP composite materials under combined cyclic and quasistatic loadings. An analysis of processes of fatigue damage accumulation in the composite materials is performed, and stages of change in the residual mechanical properties of the materials during cyclic loadings are noted. Temperature fields in the working section of samples are analyzed, and the characteristics features of temperature distribution in their destruction zone are revealed. Functions describing damage accumulation and changes in the strength and stiffness properties of the composites are introduced, which can be used to describe the behavior of the materials under fatigue loadings. A new form of representation of experimental data in the form of a fatigue sensitivity diagram is proposed, which can be employed to analyze the residual strength of structures made from composite materials. The characteristic stages of change in their residual static strength are presented in relation to the degree of preliminary cycling. It is proposed to use new material characteristics — the fatigue sensitivity threshold and the coefficient of static strength preservation.

Similar content being viewed by others

References

V. Strizhius, “Fatigue damage accumulation under quasi-random loading of composite airframe elements,” Mech. Compos. Mater., 52, No. 4, 455-468 (2016).

K. Bey, K. Tadjine, R. Khelif, A. Chemami, M. Benamira, and Z. Azari, “Mechanical behavior of sandwich composites under three-point bending fatigue,” Mech. Compos. Mater., 50, No. 6, 747-756 (2015).

V. Strizhius, “Fatigue failure criterion of laminated composites under a complex stress-strain state,” Mech. Compos. Mater., 52, No. 3, 369-378 (2016).

V. Strizhius, “Estimation of the residual fatigue life of laminated composites under a multistage cyclic loading,” Mech. Compos. Mater., No. 5, 611-622 (2016).

I. V. Grushetskii, I. P. Dmitrienko, A. F. Ermolenko, et al., Destruction of Structures from Composite [in Russian], eds. V. P. Tamuzh and V. D. Protasov, Riga, Zinatne (1986).

Yu. M. Tarnopolskii and T. Ya. Kintcis, Methods of Static Tests of Reinforced Plastics [in Russian], M., Khimiya (1981).

M. Kaminski, F. Laurin, F. J. Maire, C. Rakotoarisoa, and E. Hemon, “Fatigue damage modeling of composite structures: the ONERA viewpoint,” AerospaceLab., 1-12 (June 2015).

W. Van Paepegem and J. Degrieck, “Experimental set-up for and numerical modelling of bending fatigue experiments on plan woven glass/epoxy composites,” Compos. Struct., 51, 1-8 (January, 2001).

L. M. Kachanov, Foundations of Plasticity Theory [in Russian], M., Nauka (1969).

Yu. N. Rabotnov, Mechanics of a Deformable Solid Body [in Russian], M., Nauka (1969).

T. P. Philippidis and V. A. Passipoularidis, “Residual strength after fatigue in composites: Theory vs. experiment,” Int. J. Fatigue, 29, 2104-2116 (December, 2007).

M. V. Bannikov, V. A. Oborin, and O. V. Naimark, “Study on the stage-type destruction of titanic alloys in the mode of multi- and gigacyclic fatigue on the basis of morphology of fracture surface,” Vest. Perm. Nats. Issled. Poitekhn. Univ., Mekhanika, No. 3, 15-24 (2015).

W. Van Paepegem, R. Dechaene, and J. Degrieck, “Nonlinear correlation to the bending stiffness of a damaged composite beam,” Compos. Struct., 67, 359-364 (March, 2005).

L. Maragoni, P. A. Carraro, M. Peron, and M. Quaresimin, “Fatigue behavior of glass/epoxy laminates in the presence of voids,” Int. J. Fatigue, 95, 18-28 (October 2016).

T. P. Philippidis and T. T. Assimakopoulou, “Using acoustic emission to assess shear strength degradation in FRP composites due to constant and variable amplitude fatigue loading,” Compos. Sci. Technol., 68, 840-847 (March, 2008).

W.Van Paepegem and J. Degrieck, “Coupled residual stiffness and strength model for fatigue of fibre-reinforced composite materials,” Compos. Sci. Technol., 62, 687-696 (April, 2002).

W.Van Paepegem and J. Degrieck, “A new coupled approach of residual stiffness and strength for fatigue of fibrereinforced composites,” Int. J. Fatigue, 24, 747-762 (July, 2002).

N. L. Post, S. W. Case, and J. J. Lesko, “Modeling the variable amplitude fatigue of composite materials: A review and evaluation of the state of the art for spectrum loading,” Int. J. Fatigue, 30, 2064-2086 (December, 2008).

Y. Yamada, K. Iwata, T. Kadowaki, and T.Sumiya, “Method of reduced variables for stiffness degradation process of unidirectional CFRP composites subjected to alternating bending,” Compos. Sci. Technol., 138, 117-123 (November, 2016).

V. E. Vil’deman, Yu.V. Sokolkin, and A. A. Tashkinov, Mechanics of Onelastic Deformation and Destruction of Composite Materials 9in Russian], ed. Yu Sokolkin, M., Nauka, Fizmatlit (1997).

N. L. Post, J. Cain, K. J. McDonald, S. W. Case, and J. J. Lesko, “Residual strength prediction of composite materials: Random spectrum loading,” Eng. Fracture Mech., 75, 2707-2724 (June, 2008).

W. Van Paepegem, J. Degrieck, and P. De Baets, “Finite element approach for modelling fatigue damge in fibre-reinforced composite materials,” Composites: Part B, 32, 575-588 (October, 2001).

W. Van Paepegem and J.Degrieck, “Modelling damage and permanent strain in fibre-reinforced composites under inplane fatigue loading,” Compos. Sci. Technol., 63, 677-694 (April, 2003).

C. Qian, T. Westphal, C. Kassapoglou, and R. P. L. Nijssen, “Development of a multi-fibre unit cell for use in modeling of fatigue of unidirectional composites,” Compos. Struct. 99, 288-295 (May, 2013).

D. S. Lobanov., V. E. Wildemann, E. M. Spaskova, and A. I. Chikhachev, “Experimental investigation of defects influence on composites sandwich panels strength using digital image correlation and infrared thermography methods, PNRPU Mech. Bull., 4, 159-170 (2015).

G. La Rosa and A. Risitano, “Thermographic methodology for rapid determination of the fatigue limit of materials and mechanical components,” Int. J. Fatigue, 22, 65-73 (2000).

G. Fargione, A. Geraci, G. La Rosa, and A. Risitano, “Rapid determination of the fatigue curve by the thermographic method,” Int. J. Fatigue, 24, 11-19 (2002).

F. Libonati and L. Vergani, “Damage assessment of composite materials by means of thermographic analyses, Composites: Part B, 50, 82-90 (2013).

J. Montesano, Z. Fawaz, and H. Bougherara, “Use of infrared thermography to investigate the fatigue behavior of a carbon fiber reinforced polymer composite,” Compos. Struct., 97. 76-83 (2013).

V. Dattoma and S. Giancane, “Evaluation of energy of fatigue damage into GFRC through digital image correlation and thermography,” Composites: Part B, 47, 283-289 (2013).

D. S. Lobanov and S. V. Slovikov, “Mechanical properties of a unidirectional basalt-fiber-reinforced plastic under a loading simulating operation conditions,” Mech. Compos. Mater. 52, No. 6, 767-772 (2017).

A. V. Babushkin, D. S. Lobanov, A. V. Kozlova, and I. D. Morev, “Research of the effectiveness of mechanical testing methods with analysis of features of destructions and temperature effects,” Frattura ed Integrita Strutturale, 24, 89-95 (2013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Mekhanika Kompozitnykh Materialov, Vol. 54, No. 3, pp. 463-472 , May-June, 2018.

Rights and permissions

About this article

Cite this article

Wil’deman, V.E., Staroverov, O.A. & Lobanov, D.S. Diagram and Parameters of Fatigue Sensitivity for Evaluating the Residual Strength of Layered GFRP Composites After Preliminary Cyclic Loadings. Mech Compos Mater 54, 313–320 (2018). https://doi.org/10.1007/s11029-018-9741-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11029-018-9741-9