The mechanical and viscoelastic properties of hybrid glass/epoxy nanocomposites whose matrix was doped with 0.25, 0.5, and 1 vol.% of TiO2 nanoparticles were investigated in tension and bending. The nanoparticles were found to increase the strength of the composites by 20-30% and their stiffness by 10-20%. In addition, their creep resistance also grew. A SEM analysis of microstructure of the composites revealed that these improvements were caused by an increased adhesion between fibers and the matrix and enhanced properties of the matrix itself.

Similar content being viewed by others

References

B. Wetzela, F. Hauperta, and M. Q. Zhang, “Epoxy nanocomposites with high mechanical and tribological performance,” Compos. Sci. Technol., 63, 2055-2067 (2003).

R. Walter, K. Friedrich, V. Privalko, and A. Savadori, “On modulus and fracture toughness of rigid particulate filled high density polyethylene,” J. Adhes., 64, 87-109 (1997).

L. Nicolais, G. Guerra, C. Migliaresi, L. Nicodemo, and A. T. Di-Benedetto “Viscoelastic behavior of glass-reinforced epoxy resin,” Polym. Compos., 2, No. 3, 116-120 (1981).

W. N. Nkeuwa, B. Riedl, and V. Landry, “UV-cured clay/based nanocomposite topcoats for wood furniture. Part II: Dynamic viscoelastic behavior and effect of relative humidity on the mechanical properties,” Prog. Org. Coat., 77, No. 1, 12-23 (2014).

B. Qi, Z. Yuan, S. Lu, K. Liu, S. Li, L. Yang, and J. Yu, “Mechanical and thermal properties of epoxy composites containing graphene oxide and liquid crystalline epoxy,” Fibers Polym., 15, No. 2, 326-333 (2014).

C. E. S. Ueng, Creep modeling for composite structures, Contemporary Research in Engineering Science, Berlin, springer verlag, 563-575 (1995).

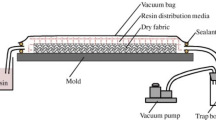

L. Y. Lin, J. H. Lee, C. E. Hong, G. H. Yoo, and S. G. Advani, “Preparation and characterization of layered silicate/glass fiber/epoxy hybrid nanocomposites via vacuum-assisted resin transfer molding (VARTM),” Compos. Sci. Technol., 66, No. 13, 2116-2125 (2006).

C. M. Manjunatha, R. Bojja, N. Jagannathan, A. J. Kinloch, and A. C. Taylor, “Enhanced fatigue behavior of a glass fiber reinforced hybrid particles-modified epoxy nanocomposite under WISPERX spectrum load sequence,” Int. J. Fatigue, 54, 25-31 (2013).

N. H. MohdZulfli, A. AbuBakar, and W. S. Chow, “Mechanical and thermal properties improvement of nano calcium carbonate-filled epoxy/glass fiber composite laminates,” High Perform. Polym., 26, 223-229 (2014).

S. Markkul, H. C. Malecki, and M. Zupan, “Uniaxial tension and compression characterization of hybrid CNS–glass fiber–epoxy composites,” Compos. Struct., 95, 337-345 (2013).

P. Karapappas, P. Tsotra, and K. Scobbie, “Effect of nanofillers on the properties of a state of the art epoxy gelcoat,” EXPRESS Polym. Lett., 5, No. 3, 218-227 (2011).

M. Atarian, H. R. Salehi, M. Atarian, and A. Shoukohfar, “Effect of oxide and carbide nanoparticles on tribological properties of phenolic-based nanocomposites,” Iran. Polym. J., 21, No. 5, 297-305 (2012).

A. Plaseied and A. Fatemi, “Tensile creep and deformation modeling of vinyl ester polymer and its nanocomposite,” J. Reinf. Plast. Compos., 28, No. 14, 1775-1788 (2009).

F. Cortes and M. J. Elejabarrieta, “Modelling viscoelastic materials whose storage modulus is constant with frequency,” Int. J. Solids Struct., 43, 7721-7726 (2006).

R. S. Lakes, Viscoelastic Solids, CRC Press, Boca Raton, Florida, (1998).

H. R. Salehi and M. Salehi, “Synthesis and mechanical properties investigation of nano TiO2/glass/epoxy hybrid nanocomposite,” Iran. J. Polym. Sci. Technol., 28, No. 4, 263-276 (2015).

Yu. J. Huan, W. J. Wei, and Yu. Jin, “Experimental study on FRP-reinforced PP ECC beams under reverse cyclic loading,” Mech. Compos. Mater., 50, No. 4, 447-456 (2014).

R. D. Maksimov and E. Plume, “Long-term creep of hybrid aramid/glass-fiber-reinforced plastics,” Mech. Compos. Mater., 37, No. 4, 271-280 (2001).

I. Viktorova, B. Dandurand, S. Alekseeva, and M. Fronya, “Modeling the creep of polymer-based nanocomposites by using an alternative nonlinear optimization approach,” Mech. Compos. Mater., 48, No. 6, 693-704 (2013).

Y. F. Zhang, S. L. Bai, X. K. Li, and Z. Zhang, “Viscoelastic properties of nanosilica-filled epoxy composites investigated by dynamic nanoindentation,” J. Polym. Sci. Part B: Polym. Phys., 47, 1030-1038 (2009).

Author information

Authors and Affiliations

Corresponding author

Additional information

Russian translation published in Mekhanika Kompozitnykh Materialov, Vol. 52, No. 5, pp. 887-904 , September-October, 2016.

Rights and permissions

About this article

Cite this article

Salehi, H.R., Salehi, M. Experimental Study on the Mechanical, Creep, and Viscoelastic Behavior of TiO2/Glass/Epoxy Hybrid Nanocomposites. Mech Compos Mater 52, 623–636 (2016). https://doi.org/10.1007/s11029-016-9612-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11029-016-9612-1