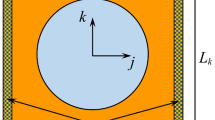

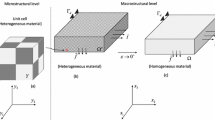

Based on the energy method and the principle of minimum total complementary potential energy, a new three-dimensional analytical model is developed. A three-dimensional analysis is performed for a unit-cell representative volume element (RVE) consisting of a monofiber, a matrix, and an interphase region. The model is evaluated using the finite-element technique. In order to study the effects of neighboring fibers on the residual stresses, several microstructural finite-element models are considered. It is proved that the RVE used in the analytical model is suitable for predicting the thermal microresidual stresses in polymer composites. In comparison with the analytical model, the finite-element analysis presents a little higher residual stresses. According to the results of the analytical model, the interfacial shear stress reaches a maximum in the vicinity of fiber ends, while the finite-element analysis gives a maximum shear stress at composite ends. This is due to the edge singularity, which is not considered in the finite-element model. Although the interphase region affects the distribution of interfacial radial stresses only slightly, it has a significant effect on the maximum interfacial radial stresses at fiber ends.

Similar content being viewed by others

References

W. D. J. Callister, Materials Science and Engineering — an Introduction, John Wiley & Sons, Inc., 1994.

J. A, Nairn and P. Zoller, “Matrix solidification and the resulting residual thermal stresses in composites,” J. Mater. Sci.;20, No. 1, 355-367 (1985).

J. K. Kim, Y. W. Mai, Engineered Interfaces in Fiber-Reinforced Composites, 1st edition, 1998.

R. D. Kurtz and N. J. Pagano, “Analysis of the deformation of a symmetrically loaded fiber embedded in a matrix material,” Compos. Eng., 1, No. 1, 13-127 (1991).

Z. M. Huang, “Strength formulae of unidirectional composites including thermal residual stresses,” Mater. Lett. 40, No. 4, 164–169 (1999).

G. C. Papanicolaou, M. V. Michalopoulou, and N. K. Anifantis, “Thermal stresses in fibrous composites incorporating hybrid interphase regions,” Composites Science and Technology, 62, 1881-1894 (2002).

Z. Hashin and W. B. Rosen, “The elastic moduli of fiber-reinforced materials,” J. Appl. Mech., 31, 223-232 (1964).

R. A. Naik “Simplified micromechanical equations for a thermal residual stress analysis of coated-fiber composites,” J. Compos. Techn. Res., 14, No. 3, 182–186 (1992).

K. Jayaraman and K. L. Reifsnider, “Residual stresses in a composite with a continuously varying Young’s modulus in the fiber/matrix interphase,” J. Compos. Mater., 26 No. 6, 770-791 (1992).

K. Jayaraman and K. L. Reifsnider, “The interphase in unidirectional fiber-reinforced epoxies: effect of residual thermal stresses,” Compos. Sci. Techn., 47, 119-129 (1993).

V. Bianchi, P. Goursat, and E. Menessier, “Carbon-fiber-reinforced YMAS glass ceramic matrix –IV Thermal residual stresses and fiber/matrix interfaces,” Compos. Sci. Techn., 58, 409-418 (1998).

C. H. Shueh and P. F. Becher, “Thermal expansion coefficient of unidirectional fiber reinforced ceramics,” J. Am. Ceram. Soc., 71, C438-C441 (1988).

M. Epstein, “The Eshelby tensor and the theory of continuous distributions of inhomogeneities,” Mech. Res. Communication, 29, No. 6, 501-506 (2002).

M. Y. Quek, “Analysis of residual stresses in a single fiber-matrix composite,” Int. J. Adhesion & Adhesives, 24, 379388 (2004).

Y. Chen, Z. Xia, F. Ellyin, “Evolution of residual stresses induced during curing processing using a viscoelastic micro-mechanical model,” J. Compos. Mater., 35, 522 (2001).

G. Karami and M. Garnich, “Micromechanical study of thermoelastic behavior of composites with periodic fiber waviness,” Composites, Pt. B, 36, 241-248 (2005).

M. M. Aghdam, A. Khojeh, “More on the effects of thermal residual and hydrostatic stresses on the yielding behavior of unidirectional composites,” Composite Structures, 62, 285-290 (2003).

T. Hobbiebrunken, B. Fiedler, M. Hojo, S. Ochiai, and K. Schulte, “Microscopic yielding of CF/epoxy composites and the effect on the formation of thermal residual stresses,” Compos. Sci. Techn., 65, 1626-1635 (2005).

L. G. Zhao, N. A. Warrior, and A. C. Long, “A thermo-viscoelastic analysis of process-induced residual stress in fibre-reinforced polymer–matrix composites,” Mater. Sci. Eng., A, 452–453, 483–498 (2007).

Kyo-Kook Jin, Y. Huang, Young-Hwan Lee, and Sung Kyu Ha., “Distribution of micro-stresses and interfacial tractions in unidirectional composites,” J. Compos. Mater., 42, 2008; 1825 originally published online Jul 17, (2008).

Y. Huang, Kyo Kook Jin, and Sung Kyu Ha, “Effects of fiber arrangement on mechanical behavior of unidirectional composites,” J. Compos. Mater., 42, 2008; 1851 originally published online Jul 17, (2008).

L. Hassel, and M. L. Dunn, “Equivalence of Eshelby inclusion theory and Wechsler–Lieberman–Read, Bowles–Mackenzie martensite-crystallography theories,” Mater. Sci. Eng., A., 285, Iss. 1-2, 180-185 (2000).

M. Y. Quek and C. Y. Yue, “Axisymmetric stress distribution in the single filament pull-out test,” Mater. Sci. Eng., A189, 105–116 (1994).

Y. Zhang, Z. Xia, and F. Ellyin, “Evolution and influence of residual stresses/strains of fiber reinforced laminates,” Compos. Sci. and Techn., 64, 1613-1621 (2004).

D. Y. Song, Takeda, N. Shinji Ogihara, “A method of stress analysis for interfacial property evaluation in thermoplastic composites,” Mater. Sci. Eng., A278, 242-246 (2000).

Maple 12, Copyright 1981-2008 by Waterloo Maple Inc.

Abaqus software, version 6.7-1, copyright 1998-2008 by ABAQUS Inc.

L. H. You and X. Y. You, “A unified numerical approach for thermal analysis of transversely isotropic fiber-reinforced composites containing inhomogeneous interphase,” J. Compos., Pt. A: Appl. Sci. and Manufacturing, 36, 728-73 (2005).

S. Nemat-Nasser and M. Hori, Micromechanics: Overall Properties of Heterogeneous Materials, Amsterdam: Elsevier Sci. Publ., 1993.

A. Matzenmiller, S. Gerlach, “Parameter identification of elastic interphase properties in fiber composites,” Composites, Pt. B, 37, 117–126 (2006).

Author information

Authors and Affiliations

Corresponding author

Additional information

Russian translation published in Mekhanika Kompozitnykh Materialov, Vol. 48, No. 3, pp. 401-418, May-June, 2012.

Rights and permissions

About this article

Cite this article

Shokrieh, M.M., Safarabadi, M. & Ghaanee, A.R. A new three-dimensional analytical model to simulate microresidual stresses in polymer matrix composites. Mech Compos Mater 48, 273–284 (2012). https://doi.org/10.1007/s11029-012-9274-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11029-012-9274-6