Abstract

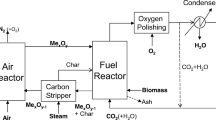

This paper analyzes the capabilities of a pilot-scale chemical looping combustion plant firing wood biomass in two stages to efficiently achieve negative carbon dioxide emissions. The utilized in situ gasification-chemical looping combustion (iG-CLC) process isolates the oxygen supply via air from the fuel conversion itself with the help of two separate fluidized bed reactors and an oxygen carrier to supply the necessary oxygen for the combustion. As a result, a relatively pure stream of carbon dioxide and steam is generated. Thus, the process makes capturing carbon emissions more feasible since it eliminates the need for the cost- and energy-intensive separation of the produced gases. A major issue when using biomass in a chemical looping plant is the high amount of the volatiles exiting unconverted. This problem was mitigated by using a two-stage fuel reactor system. Two bubbling fluidized beds were arranged one upon the other. The lower stage, where the fuel is introduced, is used to release the volatiles and partly convert them. The remaining volatiles rise up into the second stage and are further converted to a high degree. A series of experiments were carried out with a 25-kWth pilot plant located at the Hamburg University of Technology. Gas concentrations were continuously measured after both stages of the fuel reactor to see the gradual conversion of the fuel gases. Additionally, carbon slip at the exhaust was measured to show the effectiveness. The experiments with the reactor concept showed promising results since already at a reactor temperature of 850 °C, the total oxygen demand needed to oxidize the combustible component in the exhaust gas was well below 2%. The carbon dioxide (CO2) capture efficiency when using German hardwood slightly decreased to 93–96% compared to 97% for German lignite. In the future, the reactor design must prove that it scales and that the efficiency can be further increased. Nevertheless, firing biomass with a two-stage iG-CLC process might allow a cost-efficient negative carbon dioxide emission while generating heat with relatively high efficiency. Therefore, it might be a sustainable alternative to generate heat in the future.

Similar content being viewed by others

Abbreviations

- d 50 :

-

mm particle median diameter

- LHV:

-

kg/m3 lower heating value

- m OC :

-

kg/MWth specific solids inventory in the fuel reactor

- \( {\dot{n}}_i \) :

-

mol/s molar stream of component i

- P :

-

kWth thermal power output

- Q 3 :

-

– cumulative mass distribution

- R 0 :

-

wt.% oxygen carrying capacity

- X c :

-

– solid fuel conversion

- ηCC :

-

– CO2 capture efficiency, defined by Eq. (9)

- ηcomb, FR :

-

– combustion efficiency of the fuel reactor, defined by Eq. (11)

- ρ :

-

kg/m3 density

- ρ B :

-

kg/m3 bulk density

- Ω T :

-

– total oxygen demand, defined by Eq. (10)

- Ω’T :

-

– Total oxygen demand (first stage), analogous to ΩT defined by Eq. (10)

- AR:

-

air reactor

- C:

-

carbon

- CG:

-

carbonaceous gases

- FR:

-

fuel reactor

- inj:

-

injected

- Al2O3 :

-

aluminum oxide

- C:

-

carbon

- CaS:

-

calcium sulfide

- CaSO4 :

-

calcium sulfate

- CH4 :

-

methane

- CnH2m :

-

hydrocarbon (with n carbon atoms and 2 m hydrogen atoms)

- Co:

-

cobalt

- CO:

-

carbon monoxide

- CO2 :

-

carbon dioxide

- Cu:

-

copper

- Fe:

-

iron

- H2 :

-

hydrogen

- H2O:

-

water

- MexOy :

-

metal oxide (with x metal atoms and y oxygen atoms)

- Mn:

-

manganese

- N2 :

-

nitrogen

- Ni:

-

nickel

- NOx :

-

nitrogen oxides (with x oxygen atoms)

- O2 :

-

oxygen

References

Adánez J, Abad A, Mendiara T, Gayán P, de Diego LF, García-Labiano F (2018) Chemical looping combustion of solid fuels. Progress in Energy and Combustion Science 65:6–66. https://doi.org/10.1016/j.pecs.2017.07.005

de Diego LF, Gayán P, García-Labiano F, Celaya J, Abad A, Adánez J (2005) Impregnated CuO/Al2O3 oxygen carriers for chemical-looping combustion: avoiding fluidized bed agglomeration. Energy Fuels 19(5):1850–1856. https://doi.org/10.1021/ef050052f

Haus J, Lyu K, Hartge E-U, Heinrich S, Werther J (2016) Analysis of a two-stage fuel reactor system for the chemical-looping combustion of lignite and bituminous coal. Energy Technol. 4(10):1263–1273. https://doi.org/10.1002/ente.201600102

Ishida M, Jin H (1996) A novel chemical-looping combustor without NOx formation. Ind. Eng. Chem. Res. 35(7):2469–2472. https://doi.org/10.1021/ie950680s

Langorgen O, Saanum I (2018) Chemical looping combustion of wood pellets in a 150 kWth CLC reactor. International Conference on Negative CO2 Emissions. May 22–24, 2018. Göteborg, Sweden

Lyngfelt A (2013) Chemical looping combustion (CLC). In: Scala F (ed) Fluidized bed technologies for near-zero emission combustion and gasification. Elsevier, Cambridge, pp 895–930

Lyngfelt A (2015) Oxygen carriers for chemical-looping combustion. In Calcium and chemical looping technology for power generation and carbon dioxide (CO2) capture, P. Fennell and B. Anthony (ed). Elsevier, Amsterdam, pp. 221–254

Mendiara T, Gayán P, García-Labiano F, de Diego LF, Pérez-Astray A, Izquierdo MT, Abad A, Adánez J (2017) Chemical looping combustion of biomass: an approach to BECCS. Energy Procedia 114:6021–6029. https://doi.org/10.1016/j.egypro.2017.03.1737

Mendiara T, Pérez-Astray A, Izquierdo MT, Abad A, de Diego LF, García-Labiano F, Gayán P, Adánez J (2018) Chemical looping combustion of different types of biomass in a 0.5 kWth unit. Fuel 211:868–875. https://doi.org/10.1016/j.fuel.2017.09.113

Moldenhauer P, Linderholm C, Rydén M, Lyngfelt A (2019) Avoiding CO2 capture effort and cost for negative CO2 emissions using industrial waste in chemical-looping combustion/gasification of biomass. Mitig Adapt Strateg Glob Change 38(2):215. https://doi.org/10.1007/s11027-019-9843-2

Pérez-Astray A, Adánez-Rubio I, Mendiara T, Izquierdo MT, Abad A, Gayán P, de Diego LF, García-Labiano F, Adánez J (2019) Comparative study of fuel-N and tar evolution in chemical looping combustion of biomass under both iG-CLC and CLOU modes. Fuel 236:598–607. https://doi.org/10.1016/j.fuel.2018.09.003

Pikkarainen T, Teir S, Hiltunen I (2016) Piloting of bio-CLC for BECCS. 4th International Conference on Chemical Looping. September 26–28, 2016. Nanjing, China

Rydén M, Hanning M, Corcoran A, Lind F (2016) Oxygen carrier aided combustion (OCAC) of wood chips in a semi-commercial circulating fluidized bed boiler using manganese ore as bed material. Applied Sciences 6(11):347. https://doi.org/10.3390/app6110347

Schmitz M, Linderholm C, Hallberg P, Sundqvist S, Lyngfelt A (2016) Chemical-looping combustion of solid fuels using manganese ores as oxygen carriers. Energy Fuels 30(2):1204–1216

Shen L, Wu J, Xiao J, Song Q, Xiao R (2009) Chemical-looping combustion of biomass in a 10 kWth reactor with iron oxide as an oxygen carrier. Energy Fuels 23, 5, pp. 2498–2505. https://doi.org/10.1021/ef900033n

Thon A, Kramp M, Hartge E-U, Heinrich S, Werther J (2014) Operational experience with a system of coupled fluidized beds for chemical looping combustion of solid fuels using ilmenite as oxygen carrier. Applied Energy 118:309–317. https://doi.org/10.1016/j.apenergy.2013.11.023

United Nations (2015) Framework convention for climate change. http://unfccc.int/paris%20_agreement/items/9485.php.

Acknowledgments

This research was supported by a Marie Curie International Research Staff Exchange Scheme Fellowship within the 7th European Community Framework Programme.

Funding

The financial support of DFG (Deutsche Forschungsgemeinschaft) within the priority program SPP 1679: “Dynamic simulation of interconnected solids processes” is gratefully acknowledged; grant number HA 6935/2-2.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Ernst-Ulrich Hartge is deceased.

Rights and permissions

About this article

Cite this article

Haus, J., Lindmüller, L., Dymala, T. et al. Increasing the efficiency of chemical looping combustion of biomass by a dual-stage fuel reactor design to reduce carbon capture costs. Mitig Adapt Strateg Glob Change 25, 969–986 (2020). https://doi.org/10.1007/s11027-020-09917-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11027-020-09917-2