Abstract

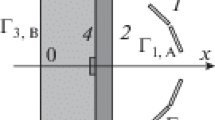

This article discusses the aspects of controlling technological parameters for the isothermal forging of cross-ribbed panels, associated with strict adherence to temperature and rate conditions of deformation. However, to produce defect-free panels, because of errors and external disturbances, the control of technological parameters based only on the measurement results of temperature field sensors is often insufficient. The metal temperature at the deformation site can only be estimated indirectly. By analogy with the Kalman filter, a method is proposed for monitoring the technological parameters of the process of isothermal forging of ribbed panels based on a set of results obtained from sensors and calculated by the finite element method. The accuracy and speed of calculating a finite element forging model in four widely used specialized software products, DeForm, QForm, Forge NxT, and Simufact Forming, were studied. Comparing the data obtained during the analysis confirmed the high degree of reliability of the modeling results and demonstrated the potential possibility of controlling the technological parameters for the production of defect-free products using the proposed method. The finite element method in a two-dimensional formulation of the problem provided an acceptable velocity for numerical simulation while monitoring the progress of operations in real time. The results obtained are relevant for metallurgical enterprises producing critical parts for the aircraft and space industries. Therefore, there are increased requirements for production processes to comply with the range of permissible changes in technological parameters.

Similar content being viewed by others

Notes

GOST 4784–97. Deformable aluminum and aluminum alloys. Grades.

OST 1.90048–90. Deformable Aluminum Alloys. Grades.

GOST R 8.585–2001. State System for Ensuring Uniform Measurement. Thermocouples. Nominal Static Conversion Characteristics.

References

Ai, Z.Y., Jiang, Y.H., Zhao, Y.Z., Mu, J.J.: Eng. Anal. Bound. Elem. 137, 1–15 (2022). https://doi.org/10.1016/j.enganabound.2022.01.006

Galkin, V.I., Vasil’ev, V.A., Paltievich, A.R., Borunova, T.I., Shelest, A.E.: The possibility of managing the process of isothermal forging free-defect ribbed panels of 01420 alloy. Technol. Light Alloy. (1), 84–90 (2017)

Peng, L.X., Tao, Y.-P., Li, H.-Q., Mo, G.-K.: Math. Probl. Eng. (2014). https://doi.org/10.1155/2014/548708

Kablov, E.N., Antipov, V.V., Oglodkova, J.S.: Metallurgist 65, 72–81 (2021). https://doi.org/10.1007/s11015-021-01134-9

Rioja, R.J., Liu, J.: Met. Mater. Trans. A 43, 3325–3337 (2012). https://doi.org/10.1007/s11661-012-1155-z

Hajjioui, E.A., Bouchaala, K., Faqir, M., Essadiqi, E.: Heliyon 9(3), e12565 (2023). https://doi.org/10.1016/j.heliyon.2022.e12565

Lukin, V.I., Zhegina, I.P., Lavrenchuk, V.P., Bazeskin, A.V., Kotel’nikova, L.V.: Weld. Int., 23. No 3, 219–222 (2009). https://doi.org/10.1080/09507110902784095

Raffeis, I., Adjei-Kyeremeh, F., Vroomen, U., Richter, S., Bührig-Polaczek, A.: materials 13(22), 5188 (2020). https://doi.org/10.3390/ma13225188

Rezaeifar, H., Elbestawi, M.: Opt. Laser. Technol. 147, 107611 (2022). https://doi.org/10.1016/j.optlastec.2021.107611

Zharov, M.V.: Meas. Techn. 65, 917–922 (2023). https://doi.org/10.1007/s11018-023-02176-y

Kulak, M.M., Myshlyaev, M.M.: Russ. Metal. Metally, vol. 2022., pp. 13–18 (2022). https://doi.org/10.1134/S0036029522010098

Bazhenov, M.G., Galkin, V.I., Zharov, M.V., Zverlov, B.V., Lisov, A.A., Orlov, L.S.: Meas. Techn., 46. No 1, 56–58 (2003). https://doi.org/10.1023/A:1023465623044

Li, X., Qian, L., Sun, C.: Int. J. Adv. Manuf. Technol. 114, 2485–2497 (2021). https://doi.org/10.1007/s00170-021-06956-0

Boiko, S.V., Larichkin, A.U.: Inverse problem of ribbed panel shape formation. J. Appl. Mech. Tech. Phys. 64(3), 549–564 (2023). https://doi.org/10.1134/S0021894423030215

Petrov, P.A., Ngok, F.V., Burlakov, I.A., Matveev, A.G.: B. Yu. Saprykin, and M. A. Petrov, “Construction of yield curves for AMg5 aluminum alloy based on full-scale tests and computer simulation,” Technol. Light Alloys. No 2, 65–74 (2022). https://doi.org/10.24412/0321-4664-2022-2-65-74

Rihacek, J., Peterkova, E., Cisarova, M., Kubicek, J.: MM Sci. J. 2020(1), 3734–3739 (2020). https://doi.org/10.17973/MMSJ.2020_03_2019151

Cechura, M., Hlaváč, J., Volejnicek, M., Kubec, V.: Adv. Mech. Eng. (2020). https://doi.org/10.1177/1687814020970308

Li, X., Huang, Q., Luo, X., Wang, P.: Appl Therm Eng 213, 118673 (2022). https://doi.org/10.1016/j.applthermaleng.2022.118673

Plogmeyer, M., Kruse, J., Stonis, M.: Microsyst. Technol. 27, 3841–3850 (2021). https://doi.org/10.1007/s00542-020-05179-9

C. Durand, L. Freund, C. Baudouin, R. Bigot, and J.-D. Guerin, “Comparison of different sensor technologies to monitor a forging process,” Proceedings of the 24th International Conference on Material Forming (ESAFORM 2021), Liege, Belgium, April, 10 (2021). https://doi.org/10.25518/esaform21.1475.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest.

Additional information

Translated from Izmeritel’naya Tekhnika, No. 10, pp. 41–28, October, 2023. Russian https://doi.org/10.32446/0368-1025it.2023-10-41-48

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Original article submitted June 29, 2023. Original article reviewed August 3, 2023. Original article accepted September 10, 2023

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zharov, M.V., Preobrazhenskii, E.V. Control of technological parameters in the process of ribbed panel forging: use of measuring equipment and mathematical modeling methods. Meas Tech 66, 776–784 (2024). https://doi.org/10.1007/s11018-024-02291-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11018-024-02291-4