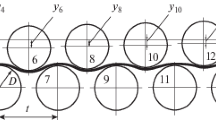

This article presents the results of a study on steel strip plasticization during straightening on roller straightening machines. The studies were conducted using the SIMULIA Abaqus finite element analysis system and with the implementation of an industrial experiment on straightening and plasma cutting of hot-rolled profile rolled stock. A significant effect of strip plasticization during straightening under conditions of alternating deformation on the deviation from the flatness of the profile rolled stock at high-tech processing is presented. The results confirmed that the minimum deviations of the strips from the flatness after cutting, not exceeding 2 mm, correspond to the straightening modes with a high plasticization of the strip at the beginning of straightening and the smallest at the end with the reduction of residual longitudinal stresses in thickness. The regression dependence of the strip plasticization on the main parameters of the straightening process based on the processing of a computational experiment was obtained, and its adequacy was established. Moreover, the parameters affecting the plasticization of the steel strip during straightening to a great extent are the number of rollers and difference in the vertical movements of the first and last rollers of the upper cassette.

The model developed for predicting the plasticization of a hot-rolled steel strip enables to develop recommendations for setting up roller machines to increase the impact on the shape of rolled products and evaluate the straightening process when designing and modernizing existing metal cross-cutting lines.

Similar content being viewed by others

References

A. I. Tselikov, P. I. Polukhin, V. M. Grebenik and et al., Machines and Units of Metallurgical Plants, 3, Machines and Units for the Production and Finishing of Rolled Products, Metallurgiya, Moscow (1988).

V. N. Shinkin, “Calculation of technological parameters of steel sheet straightening on an eleven-roller straightening machine of the Fagor Arrasate transverse cutting line,” Proizvod. Prokata, No. 8, 26–34 (2014).

V. N. Shinkin, “Calculation of the technological parameters of straightening a thin steel strip on a fifteen-roll Fagor Arrasate sheet-straightening machine,” Molod. Uchen., No. 10, 361–366 (2015).

B. Dratz, V. Nalewajk, J. Bikard, and Y. Chastel, “Testing and modeling the behavior of steel sheets for roll leveling applications,” Int. J. Mater. Form., No. 2, 519–522 (2009).

Z. Liu, “A new curvature analytical method in plate leveling process,” ISIJ Int., 58, No. 6, 1094–1101 (2018).

E. A. Maksimov and R. L. Shatalov, “A study of the parameters for hot straightening of thick steel plates on a roller straightening machine,” Metallurgist, 62, No. 1-2, 132–137 (2018).

E. A. Maksimov, R. L. Shatalov, and Yu. S. Vasiliev, “Refinement of the methodology for calculating the parameters of straightening thick sheets on a roller straightening machine,” Stal’, No. 1, 35–38 (2017).

A. E. Shelest, V. S. Yusupov, M. M. Perkas, E. N. Sheftel, V. V. Prosvirnin, and K. E. Akopyan, “Development of a method for determining the geometric and deformation parameters of straightening metal sheets on roller straightening machines,” Proizvod. Prokata, No. 7, 2–8 (2016).

I. V. Nedorezov, Simulation of the Processes of Straightening Rolled Products on Roller Machines [in Russian], AQUA-Press, Yekaterinburg (2003).

V. M. Salganik and D. A. Zaitsev, “Mathematical description of the process of cold straightening of thick sheets,” Aktual. Problemy Sovr. Nauki Tekhn. Obrazov., 1, No. 1, 56–59 (2016).

E. P. Gribkov, A. V. Zavgorodniy, E. Yu. Gavrilchenko, and A. S. Gorbenko, “Software for designing technological parameters for setting up multi-roller straightening machines,” Nauch. Vestn. Donbasskoy Gos. Mashinostr. Akad., No. 2, 33–38 (2015).

L. Madej, K. Muszka, K. Perzynski, J. Majta, and M. Pietrzyk, “Computer aided development of the leveling technology for flat products,” CIRP Annals — Manuf. Technol., 60, 291–294 (2011).

E. Silvestre, E. Saenz de Argandona, L. Galdos, and J. Mendiguren, “Testing and modeling of roll leveling process,” Key Eng. Mater., 611–612, 1753–1762 (2014).

B.-A. Behrens, T. El. Nadi, and R. Krimm, “Development of an analytical 3D-simulation model of the leveling process,” J. Mater. Proc. Technol., 211, No. 6, 1060–1068 (2011).

M. Gruber and G. Hirt, “A strategy for the controlled setting of flatness and residual stress distribution in sheet metals via roller leveling,” Procedia Eng., 207, 1332–1337 (2017).

K. A. Kotov, N. L. Bolobanova, and D. V. Nushtaev, “Modeling the stress state of a steel strip with a roller leveling machine under cyclic alternating deformations,” Steel Transl., 50, No 11, 750–755 (2019).

K. A. Kotov, N. L. Bolobanova, and D. V. Nushtaev, “Development of straightening regimes for hot-rolled strips in order to obtain rolled products for high-tech processing,” Chern. Metal., No. 2, 16–21 (2021).

N. L. Bolobanova, K. A. Kotov, and D. V. Nushtaev, “Investigation of the plasticization coefficient when straightening hot-rolled steel strips on roller straightening machines,” Stal’, No. 3, 32–36 (2020).

A. A. Korolev, Mechanical Equipment of Rolling and Pipe Shops [in Russian], Metallurgiya, Moscow (1987).

E. A. Garber, N. L. Bolobanova, and K. A. Trusov, “Application of the finite element method to reveal the causes of loss of planeness of hot-rolled steel sheets during laser cutting,” Russ. Metallurgy (Metally), No. 1, 103–108 (2018).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 66, No. 10, pp. 93–98, October, 2022. Russian DOI: https://doi.org/10.52351/00260827_2022_10_93.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bolobanova, N.L., Kotov, K.A. & Yusupov, V.S. Study and Prediction of Plasticization of Hot-Rolled Steel Strip During Straightening Under Conditions of Alternating Deformation. Metallurgist 66, 1290–1298 (2023). https://doi.org/10.1007/s11015-023-01443-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-023-01443-1