Abstract

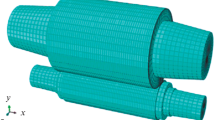

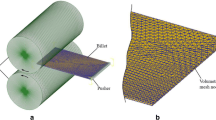

On the basis of SIMULIA Abaqus finite-element software, the stress and strain in the rollers of a four-high rolling mill may be mathematically described. The convex–concave (CVC) profiling of the rollers and the axial shift of the working rollers are taken into account here. The transverse profile of the cold-rolled strip obtained by simulation is verified experimentally. The influence of the axial shift and hydraulic flexure of the working rollers on the stress–strain state of the working rollers in cold rolling is studied. It is established that the control procedures employed for the 2100 four-stand broad-strip cold-rolling mill at PAO Severstal permit broad regulation of the transverse strip-thickness variation in rolling without significant increase in stress in the working rollers. The proposed model of the roller system is recommended for use in improving the CVC profiling of rollers and assessing roller life in sheet production.

Similar content being viewed by others

REFERENCES

Tret’yakov, A.V., Garber, E.A., and Davletbaev, G.G., Raschet i issledovanie prokatnykh valkov (Calculation and Analysis of Mill Rolls), Moscow: Metallurgiya, 1976.

Salganik, V.M., Mathematical modeling of deformations and loads of the quarto roller system to increase its durability and the quality of rolled strips, in Puti razvitiya mashinostroitel’nogo kompleksa Magnitogorskogo metallurgicheskogo kombinata. Vyp. 2. Prokatnye valki (Prospective Development of Machine Engineering Complex of Magnitogorsk Metallurgical Plant, No. 2: Rolling Rolls), Magnitogorsk: MiniTip, 1996, pp. 120–128.

Polukhin, V.P., Matematicheskoe modelirovanie i raschet na EVM listovykh prokatnykh stanov (Mathematical Modeling and Automatic Calculation of Sheet Rolling Mills), Moscow: Metallurgiya, 1972.

Grigoryan, G.G., Zheleznov, Yu.D., Chernyi, V.A., et al., Nastroika, stabilizatsiya i kontrol’ protsessa tonkolistovoi prokatki (Adjustment, Stabilization, and Control of Thin-Sheet Rolling), Moscow: Metallurgiya, 1975.

Budakva, A.A., Konovalov, Yu.V., Tkalich, K.N., et al., Profilirovanie valkov listovykh stanov (Contouring of Rolls for Sheet Mills), Kiev: Tekhnika, 1986.

Bolobanova, N.L., The development of the finite element method to improve the accuracy of modeling of elastic deformations, roll counturing, and cross-section strip on broadband mills, Materialy I mezhdunarodnoi nauchno-tekhnicheskoi konferentsii “Nauchno-tekhnicheskii progress v chernoi metallurgii–2013” (Proc. I Int. Sci.-Tech. Conf. “Scientific and Technical Progress in Ferrous Metallurgy–2013”), Cherepovets: Cherepovetsk. Gos. Univ., 2013, pp. 37–43.

Voskan’yants, A.A., Calculation of the stress-strain state of the roller system of the quarto 2500 stand, Proizvod. Prokata, 2001, no. 5, pp. 35–38.

Bochektueva, E.B., Numerical determination of the stress-strain state in the rolls and the anti-bending forces in the four-roll stand of the rolling mill, Vestn. Mosk. Gos. Tekh. Univ. im. N.E. Baumana, Ser. Mashinostr., 2010, no. 1, pp. 45–53.

Garber, E.A., Bolobanova, N.L., and Traino, A.I., Use of a finite element method to calculate roll profiles for broad-strip mills, Russ. Metall. (Engl. Transl.), 2012, vol. 2012, no. 5, pp. 370–374.

Garber, E.A. and Bolobanova, N.L., Modeling accuracy of the transverse heterogeneity of wide of strips using the finite element method, Chern. Metall., Byull. Nauchno-Tekh. Ekon. Inf., 2012, no. 12, pp. 50–53.

Kozhevnikova, I.A. and Garber, E.A., Razvitie teorii tonkolistovoi prokatki dlya povysheniya effektivnosti raboty shirokopolosnykh stanov (Development of the Theory of Thin-Sheet Rolling to Improve Performance of Broadband Mills), Cherepovets: Cherepovetsk. Gos. Univ., 2010.

Polukhin, V.P., Nikolaev, V.A., Tylkin, M.A., et al., Nadezhnost’ i dolgovechnost’ valkov kholodnoi prokatki (Reliability and Durability of Rolls for Cold Rolling), Moscow: Metallurgiya, 1976.

Konovalov, Yu.V., Ostapoenko, A.L., and Ponomarev, V.I., Raschet parametrov listovoi prokatki: spravochnik (Calculation of Parameters of Sheet Rolling: Handbook), Moscow: Metallurgiya, 1986.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by Bernard Gilbert

About this article

Cite this article

Antonov, P.V., Bolobanova, N.L. & Kozhevnikova, I.A. Roller Stress and Strain in a Broad-Strip Cold-Rolling Mill. Steel Transl. 49, 339–344 (2019). https://doi.org/10.3103/S0967091219050024

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091219050024