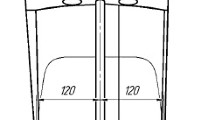

The operating conditions of piercing-mill shoes of “classical” configuration are discussed. The following main parameters of the shoe configuration affecting the sticking of metal of the hollow shell to the shoes are determined: the length of the cylindrical section of the shoes, its location relative to the axis of the piercing mill, the taper angle of the exit section, the radius of the groove of the shoes, the ovality in the deformation zone.

Computer modeling with increasing and decreasing the parameters of the shoes was carried out using QForm 2D/3D software. Of the results obtained, the following parameters of the piercing process that indicate the tendency to the sticking of the metal of the hollow shell to the shoes were selected: the forces acting on the working surface of the shoes during piercing, the time of contact between the shoes and the hollow shell, the contact area, the temperature of the working surface of the shoes during piercing.

Procedures for assessing the resistance of the shoes to the sticking of metal of the hollow shell during piercing are proposed. Three alternatives of shoes with reduced tendency to sticking of the metal of the hollow shell are developed by analyzing the modeling results using these procedures. The most promising shoe configuration was determined using computer modeling.

Similar content being viewed by others

Notes

License No. R2-U1531–250412U043.

References

F. M. Noskov, O. A. Masanskii, M. M. Manushkina, et al., History of the Science of Materials and Technologies [in Russian], Sib. Feder. Univ., Krasnoyarsk (2016).

D. V. Mikhalkin, A. A. Korsakov, O. A. Panasenko, and K. P. P’yankov, “Parameters of the deformation zone and boundary conditions of the piercing process,” Metallurgist, 65, No. 1-2, 137–146 (2021).

A. V. Korol’, A. A. Korsakov, and D. Yu. Zvonarev, “Determining the setup parameters for piercing mills with barrel-shaped rollers,” Steel in Transl., 41, No. 2, 147–150 (2011).

A. V. Korol’, Improvement of Two-Roll Screw Piercing by Modeling and Developing New Technical Solutions [in Russian], PhD Thesis, Yuzhno-Uralsky Gos. Univ., Chelyabinsk (2016).

Defects of Seamless Oil-and-Gas Pipes [in Russian]; https://extxe.com/1196/defekty-besshovnyh-neftegazoprovodnyh-trub/ (access data: 6/3/2021).

V. V. Shirokov, A. V. Korol’, A. A. Korsakov, A. O. Ashenbreiner, E. V. Khramkov, and D. V. Mikhalkin, “Experience of QForm 2D/3D modeling of tube making,” in: Proc. Int. Youth Sci.-Pract. Conf. on Innovative Technologies in Metallurgy and Mechanical Engineering [in Russian], Izd. Ural. Univ., Yekaterinburg (2014), pp. 208–211.

A. A. Korsakov, V. G. Sherkunov, E. V. Khramkov, A. V. Niklyaev, and A. G. Ulyanov, “Studying the effect of various factors on the quality of shells by computer modeling,” Byull. NTiEI: Chern. Metallurg., No. 6, 59–63 (2016).

A. A. Bogatov, D. S. Nukhov, and V. A. Toporov, “Simulation of rotary piercing process,” Metallurgist, 61, No. 1-2, 101–105 (2017).

E. Ceretti, C. Giardini, A. Attanasio, F. Brisotto, and G. Capoferri, “Rotary tube piercing study by FEM analysis: 3D simulations and experimental results,” Tube & Pipe Technology, March/April, 155–159 (2004).

M. M. Skripalenko, T. B. Huy, B. A. Romantsev, S. P. Galkin, and S. V. Samusev, “Studying features of the stress–strain state of workpieces in different helical rolling processes using computer modeling,” Stal’, No. 2, 35–39 (2019).

D. V. Mikhalkin, A. A. Korsakov, E. V. Alyutina, E. V. Khramkov, A. S. Aleshchenko, S. P. Galkin, Yu. V. Gamin, K. V. Bol’nykh, and I. N. Krivonogov, “Improvement of the precision of pipes with the use of profiled pipe billets,” Metallurgist, 64, No. 3-4, 315–321 (2020).

D. A. Akhmerov and A. V. Vydrin, “Studying the formation of the end sections of tubes during longitudinal rolling in grooves formed by a different number of rolls,” Chern. Metally, No. 1, 44–48 (2021).

E. V. Alyutina, A. A. Korsakov, D. V. Mikhalkin, A. V. Korol’, A. G. Ul’yanov, and A. V. Niklyaev, “Neural-network analysis of mandrel life in a piercing mill,” Steel in Transl., 49, No. 2, 134–136 (2019).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 66, No. 1, pp. 32–39, January, 2022. Russian DOI: https://doi.org/10.52351/00260827_2022_01_32.

Rights and permissions

About this article

Cite this article

Korsakov, A.A., Mikhalkin, D.V., Akhmerov, D.A. et al. Study of the Operating Conditions of Piercing Mill Shoes Using Computer Modeling. Metallurgist 66, 33–44 (2022). https://doi.org/10.1007/s11015-022-01297-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-022-01297-z