Abstract

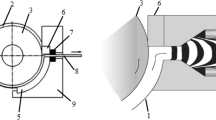

With continuous pressing by Conform method, the required pressing pressure is created in split container (shoe or die holder) by the contact friction stresses between surface of annular groove of impeller and workpiece fed into it. These stresses, as in rolling, play a positive role and are active. The size of contact area between workpiece and impeller is determined by the shoe length, which also affects the energy-force parameters of continuous pressing process, such as pressing pressure, torque on wheel shaft, and electric driving power. Based on analytical dependences obtained in the study of energy-force conditions, a method has been developed for calculating the minimum shoe length, which is necessary for implementation of a stable metal extrusion process, taking into account metal rheology and parameters of deformation zone. In this case, parameters of complete contact zone and incomplete contact zone between workpiece and surface of the deforming tool are calculated. The use of the obtained engineering solution in analysis of influence of the main design and technological parameters on efficiency of the profile production process by Conform method allows not to use special software systems (such as Deform 3D) but to solve the problem by using publicly available programs (e.g., Microsoft Excel). The results of comparing calculations with experimental data obtained under industrial conditions showed that the deviation was no more than 10%, which confirms reliability of the formulated solutions and the developed mathematical models.

Similar content being viewed by others

Data availability

Not applicable.

References

Extrusion technology. BWE Ltd. https://bwe.co.uk/about/ Accessed 19 April 2021

Dalian Konform Developed New 300H Machine. Dalian Konform Technical Company Ltd. http://en.konform.cn/news/124.html Accessed 19 April 2021

The Continuous Rotary Extrusion Process. Holton Crest Limited. https://holtoncrest.com/continuous-rotary-extrusion-process/ Accessed 19 April 2021

Belyaev SV, Gorokhov YV, Gubanov IY et al (2015) Device for continuous casting and pressing of non-ferrous metals and alloys by conformal method. Patent RU 156614:U1

Belyaev SV, Frolov VF, Deev VB et al (2019) Device for horizontal continuous casting and pressing of metal by Conform method. Patent RU 2709309:C1

Skuratov AP, Gorokhov YV, Popiyakova NP et al (2020) Continuous casting and pressing device. Patent RU 2711276:C1

Thomas B, Derguti F, Jackson M (2016) Continuous extrusion of a commercially pure titanium powder via the Conform process. Mater Sci Technol 33(7):899–903. https://doi.org/10.1080/02670836.2016.1245256

Gorokhov YV, Belyaev SV, Uskov IV, Konstantinov IL, Gubanov IY, Gorokhova TY, Hramtsov PA (2017) Application of combined casting–pressing for the fabrication of aluminum wire for soldering waveguides. Russ J Non-Ferrous Met 58:75–79. https://doi.org/10.3103/S1067821217010059

Gorokhov YV, Belyaev SV, Gubanov IY, Konstantinov IL (2016) Line of continuous casting-pressing of non-ferrous metals. Tsvetnye Metally 3:69–74. https://doi.org/10.17580/tsm.2016.03.11

Bhatta L, Pesin A, Zhilyaev A, Tandon P, Kong C, Yu H (2020) Recent development of superplasticity in aluminum alloys: a review. Metals 10(1):77. https://doi.org/10.3390/met10010077

Lesniak D, Wassermann A, Dziki M et al (2019) Susceptibility for extrusion welding of Al-Mg alloys. Arch Civ Mech Eng 19(1):20–31. https://doi.org/10.1016/j.acme.2018.08.005

Mitka M, Gawlik M, Bigaj M, Szymanski W (2015) Continuous rotary extrusion (CRE) of flat sections from 6063 alloy. Key Eng Mater 641:183–189. https://doi.org/10.4028/www.scientific.net/KEM.641.183

Cho JR, Jeong HS (2011) Parametric investigation on the curling phenomenon in CONFORM process by three-dimensional finite element analysis. J Mater Process Technol 110(1):53–63. https://doi.org/10.1016/S0924-0136(00)00658-0

Bozzi S, Vedani M, Lotti D, Passoni G (2013) Extrusion of aluminium hollow pipes: seam weld quality assessment via numerical simulation. Metall Sci and Tech 27(2):20–29

Manninen T, Ramsay P, Korhonen AS (2010) Three-dimensional numerical modeling of continuous extrusion. J Mater Process Technol 177:600–603

Kumar Sinha D, Kumar S, Kumar A (2012) Virtual design and fabrication of a continuous extrusion setup with process analysis. Int J Eng Res and Tech l(8):1–6

Yu J, Zhao G, Cui W, Chen L, Chen X (2019) Evaluating the welding quality of longitudinal welds in a hollow profile manufactured by porthole die extrusion: experiments and simulation. J Manuf Process 38:502–515. https://doi.org/10.1016/j.jmapro.2019.01.044

Perlin IL, Reitbarg LKh (1975) Metal pressing theory. Metallurgija, Moscow.

Ermanok MZ, Feigin VI, Sukhorukov NA (1977) Extrusion of profiles from aluminum alloys. Metallurgija, Moscow

Shcherba VN, Raitbarg LK (1995) Metal pressing technology. Metallurgija, Moscow

Kornilov VN (1993) Continuous pressing and welding of aluminum alloys. Pedagogical Institute, Krasnoyarsk

Kim YH, Cho JR, Kim KS, Jeong HS, Yoon SS (200) A study of the application of upper bound method to the conform process. J Mater Process Tech 97:153-157.

Cao F, Wen J, Ding H, Wang Z, Li Y, Guan R, Hou H (2013) Force analysis and experimental study of pure aluminum and Al–5%Ti–1%B alloy continuous expansion extrusion forming process. Trans Nonferrous Metals Soc China 23(1):201–207. https://doi.org/10.1016/S1003-6326(13)62447-4

Gorokhov YuV, Sherkunov VG, Dovzhenko NN et al (2013) Fundamentals of designing processes for continuous pressing of metals: monograph. Siberian Federal University, Krasnoyarsk.

Gorokhov YV, Timofeev VN, Belyaev SV et al (2017) Conform installation structural elements design methods. ARPN J Eng Appl Sci 12(9):4742–4746

Gorokhov YV, Belyaev SV, Gubanov IY (2016) Combined casting and pressing of aluminum wire: monograph. Palmarium Academic Publishing, Saarbrucken

Tretyakov AV, Zyuzin VI (1973) Mechanical properties of metals and alloys during pressure treatment. Metallurgija, Moscow.

Okhrimenko YaM, Shcherba VN, Nedugov AV et al (1983) Derivation of the equation of the relationship between the properties of aluminum alloys with the parameters of hot deformation.

Aluminum tubes. Alutube Ltd. http://alutube.ru/index Accessed 08 August 2021

Author information

Authors and Affiliations

Contributions

The authors declare that they are all participants in the work and none of them performed only administrative functions.

Corresponding author

Ethics declarations

Ethics approval

The work contains no libelous or unlawful statements, does not infringe on the rights of others, or does not contain material or instructions that might cause harm or injury.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Belyaev, S.V., Gubanov, I.Y., Gorokhov, Y.V. et al. Analysis of the shoe length for continuous pressing equipment with a horizontal rotation axis of impeller. Int J Adv Manuf Technol 118, 1295–1303 (2022). https://doi.org/10.1007/s00170-021-08009-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08009-y