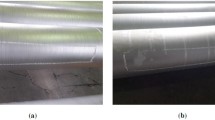

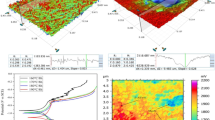

This work studies the oxide film structure on the surface of cylindrical ingots made of 6000 series aluminum alloy after homogenization annealing and tests with alternating immersion in an electrolyte based on sodium chloride using electron microscopy and energy dispersive analysis. Results reveal a 40–200% increase in weight loss in areas covered with white bloom when the active environment impacts the ingot surface due to the presence of defects in the oxide film structure. In addition, the corrosion rate increases by a factor of 2–3 compared to the clean zones, while passivation processes are not noted on both parts of the surface. Defects in the structure of the oxide film are associated with the partial reduction of aluminum oxide during diffusion annealing at the site of contact with organic contaminants.

Similar content being viewed by others

References

E. N. Smirnov et al., “Complete evaluation of extruded aluminum section and semiproduct mechanical properties under conditions of typical regional manufacturer Altek,” Metallurgist, 61, No. 9–10, 878–883 (2018).

F. Eckermann, T. Suter, P. J. Uggowitzer, A. Afseth, and P. Schmutz, “The influence of MgSi particle reactivity and dissolution processes on corrosion in Al-Mg-Si alloys,” Electrochim. Acta, 54, 844–855 (2008).

M. H. Larsen, J. C. Walmsley, O. Lunder, and K. Nisancioglua, “Effect of excess silicon and small copper content on intergranular corrosion of 6000-series aluminum alloys,” J. Electrochem. Soc., 157, 61–68 (2010).

K. El-Menshawy, A.-W.A. El-Sayed, M. E. El-Bedawy, H. A. Ahmed, and S. M. El-Raghy, “Effect of aging time at low aging temperatures on the corrosion of aluminum alloy 6061,” Corros. Sci., 54, 167–173 (2012).

G. Svenningsen, M. Hurlen Larsen, J. E. Lein, J. H. Nordlien, and K. Nisancioglu, “Intergranular corrosion of extruded AA6000-series model alloys,” in: Proc. of the 9th Intern. Conf. on Aluminum Alloys, Light Metal Surface Science (2004).

Y. N. Mansurov, D. S. Kadyrova, and J. Rakhmonov, “Dependence of corrosion resistance for aluminum alloys with composition increased impurity content,” Metallurgist, 62, No. 11–12, 1181–1186 (2019).

D. V. Pronichev, L. M. Gurevich, O. V. Slautin, and V. F. Parfenov, “Oxide film structure on aluminum alloy 6000 series cylindrical ingot surface,” Metallurgist, 64 (1–2), 176–184 (2020).

A. Guilhaudis, “Some aspects of the corrosion resistance of aluminum alloys in marine atmosphere,” Anti-Corrosion, No. 3, 12–16 (1975).

V. S. Sinyavsky, et al., Corrosion and Protection of Aluminum Alloys [in Russian], Metallurgiya, Moscow (1986).

E. H. Hollingsworth, H. Y. Hunsicker, J. R. Corrosion, Sr. Davis et al., “Corrosion of aluminum and aluminum alloy (9th ed.),” in: Metals Handbook. ASM Intern., Materials Park, , 13, OH (1987), pp. 583–609.

I. V. Dubova et al., “Electrochemical behavior of 6XXX series aluminum alloys in electrolytes containing chloride ions,” J. of Physics: Conf. Ser. IOP Publishing, 1679, No. 4, 042095 (2020).

I. J. Polmear, Light Alloys from Traditional Alloys to Nanocrystals, 4th ed. Oxford, UK: Elsevier (2006).

J. R. Davis, Corrosion of Aluminum and Aluminum Alloys, 1st ed. Materials Park, OH, ASM International (1999).

N. L. Sukiman, X. Zhou, N. Birbilis, A. E. Hughes, J. M. C. Mol, S. J. Garcia, X. Zhou, and G. E. Thompson, “Durability and corrosion of aluminum and its alloys: overview, property space, techniques and developments,” in: Aluminum Alloys – New Trends in Fabrication and Applications, Intech, Rijeka, Croatia (2012).

A. Shi, B. A. Shaw, and E. Sikora, “The role of grain boundary regions in the localized corrosion of a copper-free 6111-like aluminum alloy,” Corrosion, 61, No. 6, 534–547 (2005).

Y. N. Mansurov, A. R. Rikhsiboev, and S. Y. Mansurov, “Features of multicomponent secondary aluminum alloy structure formation,” Metallurgist, 63 (11–12), 1303–1312 (2020).

S. K. Kairy, et al., “On the intergranular corrosion and hardness evolution of 6xxx series Al alloys as a function of Si:Mg ratio, Cu content, and aging condition,” Corrosion, 73, No. 10, 1280–1295 (2017).

W. J. Liang, et al., “General aspects related to the corrosion of 6XXX series aluminum alloys: Exploring the influence of Mg/Si ratio and Cu,” Corros. Sci., 76, 119–128 (2013).

A. P. Sekhar, A. B. Mandal, and D. Das, “Mechanical properties and corrosion behavior of artificially aged Al–Mg–Si alloy,” J. Mater. Res. Tech., 9, No. 1, 1005–1024 (2020).

R. Braun, “Investigation on microstructure and corrosion behavior of 6XXX series aluminum alloys,” Mater. Sci. Forum. Trans. Tech. Publ. Ltd., 519, 735–740 (2006).

R. Braun, “On the stress corrosion cracking behavior of 6XXX series aluminum alloys”, Int. J. Mater. Res., 101, No. 5, 657–668 (2010).

K. El-Menshawy, et al., “Effect of aging time at low aging temperatures on the corrosion of aluminum alloy 6061,” Corros. Sci., 54, 167–173 (2012).

Yu. V. Borisoglebskiy, N. M. Galevskiy, N. M. Kulagin, et al, Aluminum Metallurgy [in Russian], Nauka, Novosibirsk (1999).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 65, No. 5, pp. 40–44, May, 2021. Russian DOI: 10.52351/00260827_2021_05_52.

Rights and permissions

About this article

Cite this article

Pronichev, D.V., Gurevich, L.M., Slautin, O.V. et al. Influence of the Surface Condition of Cylindrical Aluminum Alloy Ingots of Series 6000 on Corrosion Resistance. Metallurgist 65, 538–548 (2021). https://doi.org/10.1007/s11015-021-01188-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-021-01188-9