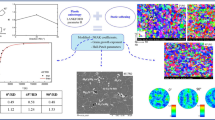

The microstructure and superplasticity indices are compared for specimens of alloy AA5083 prepared by two technologies: using intermediate heterogenization annealing and without it. As a result of heterogenization β -phase is separated that during recrystallization stimulates new grain growth, and therefore the grain size within specimens is smaller by almost a factor of two than for specimens not subjected to annealing. Use of heterogenization annealing provides a relative elongation up to 650% at 550°C and a constant strain rate of 1·10−3 sec−1, and lower residual porosity. Sheet prepared by this technology makes it possible to increase forming rate by several factors.

Similar content being viewed by others

References

H. H. Chen, J. Y. Wang, J. Lee, and S. Lee, “Superplasticity of AA5083 alloy as processed by equal channel angular extrusion,” J. Alloys and Compounds, 460, 305–308 (2008).

K. T. Park, D. Y. Hwang, Y. K. Lee, et al., “High strain rate superplasticity of submicrometer grained 5083 Al alloy containing scandium fabricated by severe plastic deformation,” Mater. Sci. and Eng. A, A341, 273–281 (2003).

N. E. Prasad and R. J. H. Wanhill, Aerospace Materials and Material Technologies, Vol. 1: Aerospace Materials (2017).

A. V. Mikhailovskaya, V. K. Portno, A. D. Kotov, et al., “Effect of adding chromium on internal friction and superplasticity of alloys of the Al–Mg system,” Metal Science and Heat Treatment, 54, No. 5-6, 276-280 (2012).

R. L. Hecht, K. Kannan in: A. K. Gosh and T. R. Bieler T.R. (editors), Superplasticity and Superplastic Forming, TMS, Warrendale, PA (1995).

Microstructure and Properties of Materials, Edited by: Li J.C.M. USA: University of Rochester (1996).

S. J. Hosseinipour, “An investigation into hot deformation of aluminum alloy 5083,” Materials and Design, 30, 319–322 (2009).

D. Y. Maeng, J. H. Lee, and S. I. Hong, “The effect of transition elements on the superplastic behavior of Al–Mg alloys,” Mat. Sci. Eng., A357, 188–195 (2003).

C. Xu, Z. Horita, M. Furukawa, and T. G. Langdon, “Using equal-channel angular pressing for the production of superplastic aluminum and magnesium alloys,” J. Mater. Eng. Perform, 13, 683–690 (2004).

A. V. Pozdnyakova and V. K. Portnoi, “Aspect of structural variations in superplastic strain of alloy AMg4,” Russian J. Non-Ferrous Metals, 45, No. 1, 31–36 (2004).

S. Y. Chang, B. D. Ahn, S. K. Hong, et al., “Tensile deformation characteristics of a nano-structured 5083 Al alloy,” J. Alloys Compd., 386, 197–201 (2005).

K. Kannan, J. S. Vetrano, and C. H. Hamilton, “Effects of alloy modification and thermomechanical processing on recrystallization of Al–Mg–Mn alloys,” Metal. Mater. Trans. A, 27A, 2947–2957 (1996).

O. Engler and S. Miller-Jupp, “Control of second-phase particles in the Al–Mg–Mn alloy AA 5083,” J. Alloys and Compounds, 689, 998–1010 (2016).

A. V. Mikhaylovskaya, V.K. Portnoy, A. G. Mochugovskiy, et al., “Effect of homogenisation treatment on precipitation, recrystallization and properties of Al – 3% Mg – TM alloys (TM = Mn, Cr, Zr),” Materials & Design, 109, 197–208 (2016).

V. K. Portnoy, D. S. Rylov, V. S. Levchenko, and A. V. Mikhaylovskaya, “The influence of chromium on the structure and superplasticity of Al–Mg–Mn alloys,” J. Alloys and Compounds, 581, 313–317 (2013).

D. H. Shin and W.-J. Kim, “Superplasticity of fine-grained 7475 Al alloy and a proposed new deformation mechanism,” Acta Mater., 45, No. 12, 5195–5202 (1997).

A. Smolej, M. Gnamuš, and E. Slaček, “The influence of the thermomechanical processing and forming parameters on superplastic behavior of the 7475 aluminum alloy,” J. Mater. Proc. Technology, 118, No. 1-3, 397–402 (2001).

M. S. Kishchik, A. V. Mikhailovskaya, V. S. Levchenko, et al., “Formation of fine-grained structure and superplasticity in commercial aluminum alloy 1565ch,” Metal Sci. and Heat Treatment., 58, No. 9, 543–547 (2017).

A. A. Kishchik, A. V. Mikhaylovskaya, V. S. Levchenko, and V. K. Portnoy, “Formation of microstructure and the superplasticity of Al–Mg-based alloys,” Physics Metals and Metallography, 118, 96–103 (2017).

E. N. Chumachenko, V. K. Portnoi, and I. V. Logashina, “Mechanical tests and construction of analytical models of the behavior of materials under superplastic conditions. Part II,” Metallurgist, 59, 69–75 (2015).

A. V. Mikhaylovskaya, O. A. Yakovtseva, I. S. Golovin, et al., “Superplastic deformation mechanisms in fine-grained Al–Mg based alloys,” Mater. Sci. & Eng. A, 627, 31–41 (2015).

Z. C. Wang, T. J. Davies, and N. Ridle, “Effect of porosity on the superplasticity of an alumina,” Scr. Metallurg. Mater., 30, No. 3, 355–359 (1994).

H. Xiang, Q. L. Pan, X. H. Yu, et al., “Superplasticity behavior of Al–Zn–Mg–Zr cold-rolled alloy sheet with minor Sc addition,” Mater. Sci. and Eng. A, 676, 128–137 (2016).

S. Sagat and D. M. R. Taplin, “Fracture of a superplastic ternary brass,” Acta Metall., 24, No. 4, 307–315 (1976).

C. W. Humphries and N. Ridley, “Cavitation during the superplastic deformation of an α/β brasses,” J. Mater. Sci., 13, No. 11, 2477–2482 (1978).

O. A. Yakovtseva, A. V. Mikhailovskaya, A. D. Kotov, and V. K. Portnoi, “Effect of alloying on superplasticity of two-phase brasses,” Phys. Metals and Metallography, 117, No. 7, 742–748 (2016).

O. A. Yakovtseva, A. V. Mikhailovskaya, A. V. Pozdniakov, et al., “Superplastic deformation behaviour of aluminium containing brasses,” Mater. Sci. & Eng. A, 674, 135–143 (2016).

Work was performed with financial support of the RF Ministry of Education and Science within the scope of the main part of a state2 assignment for higher education establishments for 2017-2019 No. 11.7172.2017/8.9.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 62, No. 5, pp. 45–49, May 2018. Original article submitted June 27, 2017.

Rights and permissions

About this article

Cite this article

Portnoi, V.K., Yakovtseva, O.A., Kishchik, A.A. et al. Use of Heterogenization for Improving Alloy AA5083 Superplasticity Indices. Metallurgist 62, 449–455 (2018). https://doi.org/10.1007/s11015-018-0680-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-018-0680-4