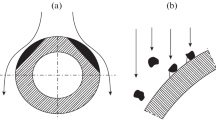

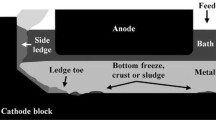

The growth of the modern aluminum industry is characterized by a search for methods of increasing the capacity of electrolyzers, reducing emissions into the environment, and reducing energy consumption. In the production of aluminum, the specific electricity consumption can be reduced and current efficiency increased by decreasing the distance between the anode and cathode and at the same time reducing the horizontal currents in the molten aluminum. The horizontal component of the current density can be reduced by placing electrical insulation between the cathode carbon block and the bloom on the section ‘crust boundary – projection of the anode periphery on the bottom block’. Heatproof materials with the following properties are technologically most effective and economical for use as electrical insulation: good adhesion to steel, chemical resistance to cryolite-alumina melt, and quite low ultimate strength in compression. Low strength and stiffness are needed because during thermal expansion of the materials in the bottom block during the period of heating the tank to the working temperature with high resistance to compression there is a risk of the load increasing on the carbon cathode block and cracks forming in it. Moreover, such properties of the material will make it possible to decrease the risk of fracture of the cathode carbon block if the volume of the electric-insulation insert increases as a result of the electrolyte penetrating into it. The results of the investigations of the mechanical properties of some heatproof materials for use as electrical insulation of blooms in aluminum electrolyzers at high temperatures are presented in order to optimize the composition.

Similar content being viewed by others

References

P. Thibeault, S. Becasse, A. Blais, et al., “Rio Tinto Alcan AP4X low energy cell development,” Light Metals, 543–547 (2013).

Feng Naixiang, Peng Jianping, Wang Yaowu, et al., “Research and application of energy saving technology for aluminum reduction in China,” Light Metals, 563–568 (2012).

Liang Xuemin, Chen Xiping, Guo Long, et al., “Industrial running of the 530 kA pot line in North-Western China,” Light Metals, 803–807 (2014).

V. Bojarevics, “MHD of aluminum cells with the effect of channels and cathode perturbation elements,” Light Metals, 609–614 (2013).

V. Yu. Bazhin, V. M. Sizyakov, V. N. Brichkin, et al., Patent 2010154740 RF, IPC C25C03/08, “Cathode setup of an aluminum electrolyzer,” subm. 12.30.2012, publ. 07.10.2012.

Li Jie and Lu Xiao-jun, “Industrial test of low-voltage energy-saving aluminum reduction technology,” Light Metals, 399–404 (2010).

Wang Ziqian and Feng Naixiang, “Study of surface oscillation of liquid aluminum in 168kA aluminum reduction cells with a new type of cathode design,” Light Metals, 485–488 (2010).

R. Kaenel and J. Antille, “Modeling of energy saving by using cathode design and inserts,” Light Metals, 569–574 (2011).

H. Nestle (ed.), Builder’s Handbook: Construction Engineering, Design, and Technology [Russian translation], Tekhnosfera, Moscow (2007), Vol. 1.

A. A. Shaimukhametov and A. I. Gabitov, “Adhesion of cement composition to steel,” Baskir. Khim. Zh., 14, 83–85 (2007).

P. V. Polyakov (work head), Report on R&D Work on Methods for Decreasing Heat Losses and Electric Resistance and Increasing MHD Stability of Electrolyzers for Production of Aluminum, Siberia Federal University, Krasnoyarsk (2014), No. GR. 114121750014, Inv. No. 315041670003.

V. M. Sizyakov, V. Yu. Bazhin, R. K. Patrin, et al., “Increasing the resistance of the carbon bottom of high-amperage electrolyzer,” Novye Ogneupory, No. 5, 5–8 (2013).

G. V. Arkhipov and A. G. Arkhipov, Patent 2178884 RF, IPC7 G01N25/00, “Setup for investigation of the physical-mechanical properties of carbon products,” subm. 01.23.2001, publ. 01.27.2002.

A. G. Gorshkov, V. N. Troshin, and V. I. Shalashilin, Resistance of Materials, Fizmatlit, Moscow (2005).

www.markmet.ru/ogneupornie-materialy/ogneupornye-betony-na-zhidkomstekle, acces. Dec. 23, 2015.

This article was prepared using the results of work performed as part of the Federal Targeted Program on Research and Development in High-Priority Directions of Development of the Scientific and Technical Complex of Russia in 2014– 2020, under agreement No. 14.579.21.0032 on the theme “Development of a technology for the production of aluminum with reduction of electricity consumption in operating electrolyzers by 300–1000 kW·h/ton aluminum.” The unique identifier is RFMEFI57914X0032.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 6, pp. 73–77, June, 2016.

Rights and permissions

About this article

Cite this article

Shakhrai, S.G., Mikhalev, Y.G., Kalinovskaya, T.G. et al. Investigation and Choice of Materials for the Electrical Insulation of the Steel Bloom of an Aluminum Electrolyzer. Metallurgist 60, 622–628 (2016). https://doi.org/10.1007/s11015-016-0341-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-016-0341-4