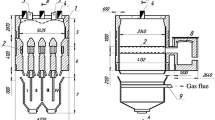

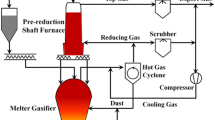

It is shown based on studies of the changes in the composition of the gases and temperature in the preliminary charge that the performance indices of coke-fired shaft furnaces are determined by the conditions under which the oxidizing zone is formed so as to produce the greatest possible amount of heat. It is shown that the size of this zone increases with an increase in the rate of filtration of the air blast, enrichment of the blast with oxygen, and the use of low-activity coke in the form of lumps of limited size. To maximize the reheating of the melt, it is necessary to increase the average size of the lumps and the flow rate of the air blast in order to increase the height of the preliminary charge.

Similar content being viewed by others

References

L. M. Marienbach, Metallurgical Principles of the Cupola Process [Russian translation], Mashgiz, Moscow (1960).

N. V. Lavrov, Physicochemical Principles of the Combustion and Gasification of Fuel [in Russian], Metallurgizdat, Moscow (1957).

V. G. Lisienko,Ya. M. Shchelokov, and M. G. Ladygichev, Fuel: Efficient Combustion, Management, and Industrial Use: Handbook [in Russian], Teplotekhnik, Moscow (2002).

D. M. Khzmalyan, Theory of Heating Processes [in Russian], Energoatomizdat, Moscow (1990).

Ya. M. Gordon, B. A. Bokovikov,V. S. Shvydkii, et al., Thermal Performance of Shaft Furnaces and Units Operated with a Packed Bed [in Russian], Metallurgiya, Moscow (1989).

V. I. Matyukhin,V. V. Madison,V. B. Pol’, et al., The Cupola Process for Melting Cast Iron [in Russian], UGTU-UPI, Ekaterinburg (2003).

O. N. Bryukhanov and B. S. Mastryukov, Aerodynamics, Combustion, and Heat Transfer [in Russian], Nedra, St. Petersburg (1994).

Z. F. Chukhanov, Selected Problems on Fuel and Power Engineering [in Russian], Akad. Nauk SSSR, Moscow (1961).

V. V. Struminskii, “Toward a theory of multicomponent gases and disperse media,” in: Hydrodynamic Problems in Industrial Processes: Symposium, edited by V. V. Struminskii, Nauka, Moscow (1988), pp. 5–19.

N. A. Barinov, Water-Cooled Cupolas and Their Possible Metallurgical Uses [in Russian], Mashinostroenie, Moscow (1964).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 5, pp. 38–43, May, 2013.

Rights and permissions

About this article

Cite this article

Matyukhin, V.I., Konovalov, I.S. & Matyukhina, A.V. Selecting efficient parameters for the coke charge of shaft-type melting furnaces. Metallurgist 57, 389–396 (2013). https://doi.org/10.1007/s11015-013-9743-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-013-9743-8