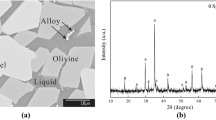

The distribution behavior of vanadium in factory steel slags with high basicity (CaO/SiO2) and enrichment of vanadium in slag modified by SiO2 and Al2O3 were investigated. The mineralogical phases and vanadium distribution were characterized by scanning electron microscopy (SEM), energy disperse x-ray spectrometry (EDS), and powder x-ray diffraction (XRD). The results indicate that vanadium is distributed in the major phase of calcium silicate and the phase of the matrix in steel slag with high basicity. The V2O5 contents in the dicalcium silicate phase increase with declining basicity of steel slag, whereas, in the slag modified by SiO2 and Al2O3, V is concentrated in the solid solution of Ca3[(V, P, Si)O4]2 (the V-enrichment phase), which is identified with the results based on synthetic steel slag containing vanadium. The relation between chemical composition and crystallization behavior and grain size of Ca3[(V, P, Si)O4]2 is also discussed. It is found that high MgO in the slag will form magnesium aluminate, and the V-enrichment phase grains grow larger than that obtained in synthetic slag.

Similar content being viewed by others

References

R. R. Moskalyk and A. M. Alfantazi, “Processing of vanadium: A review,” Miner. Eng., 16, No. 9, 793–805 (2003).

H. Preblinger, “Vanadium in converter slags,” Steel Res., 73, No. 12, 522–525 (2002).

G. Z. Ye, E. Burstrom, M. Kuhn, and J. Piret, “Reduction of steel-making slags for recovery of valuable metals and oxide materials,” Scand. J. Metall., 32, No. 1, 7–14 (2003).

X. R. Wu, L. S. Li, and Y. C. Dong, “Experimental crystallization of synthetic V-bearing steelmaking slag with Al2O3 doped,” J. Wuhan Univ. Technol.-Mater. Sci. Ed., 20, No. 2, 63–66 (2005).

Y. C. Dong, X. R. Wu, and L. S. Li, “Precipitation and growth of V-concentrating phase in synthetic V-bearing steelmaking slag,” ISIJ Int., 45, No. 9, 1238–1242 (2005).

L. S. Li, L. S. Wu, Y. L. Su, L. Yu, X. R. Wu, and Y. C Dong, “Influence of Al2O3 on vanadium concentration in V-bearing steelmaking slag,” Acta Metall. Sin., 44, No. 5, 603–608 (2008).

X. R. Wu, L. S. Li, and Y. C. Dong, “Influence of P2O5 on crystallization of V-concentrating phase in V-bearing steelmaking slag,” ISIJ Int., 47, No. 3, 402–407 (2007).

L. S. Li, X. R. Wu, L. Yu, and Y. C. Dong, “Effect of TiO2 on crystallization of V-concentrating phase in V-bearing steelmaking slag,” Ironmak. Steelmak., 35, No. 5, 367–370 (2008).

F. Chayes, “On the base of grain-size measurements made in thin section,” J.Geol., 58, 156–160 (1950).

D. D. Eberl, V. A. Drits, and J. Srodon, “Deducing growth mechanisms for minerals from the shapes of crystal size distributions,” Am. J. Sci., 298, No. 6, 499–533 (1998).

J. J. Moore, Chemical Metallurgy, Butterworths, London (1981), pp. 152–153.

B. D. Marsh, “Crystallization of silicate magmas deciphered using crystal size distributions,” J. Am. Ceram. Soc., 90, No. 3, 746–757 (2007).

E. D. Kile and D. D. Eberl, “Crystal growth mechanisms in miarolitic cavities in the Lake George ring complex and vicinity, Colorado,” Am. Miner., 84, No. 5–6, 718–724 (1999).

O. I. Funda and D. H. Warren, “Quartz crystal size distribution of the Ordovician Millbrig K-bentonite,” J. Volcanol. Geotherm. Res., 184, No. 3–4, 285–291 (2009).

Acknowledgments

We thank New Zealand Steel Limited, Auckland, New Zealand, for providing samples of vanadium-bearing steel slag. The authors would also like to acknowledge the financial support of the Anhui Provincial Natural Science Foundation (Project No. 090414150) and the Natural Science Foundation of Education Department of Anhui, China (KJ2009A69, KJ2008A038). The experimental support from the International Cooperation Project from Anhui Science & Technology Department of China (No. 09080703019) is also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in Metallurg, No. 6, June, 2011.

Rights and permissions

About this article

Cite this article

Wu, X., Li, L. & Dong, Y. Enrichment and crystallization of vanadium in factory steel slag. Metallurgist 55, 401 (2011). https://doi.org/10.1007/s11015-011-9444-0

Received:

Published:

DOI: https://doi.org/10.1007/s11015-011-9444-0