Abstract

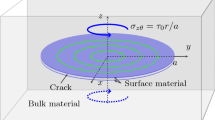

The bending fracture problem of two thickness-through collinear cracks of equal length in a flexible nanoplate with surface stress is analyzed. Using the Kirchhoff thin plate theory together with surface elasticity theory, a mixed boundary value problem is given for applied bending moment, twisting moment and shear force, and solved by use of the Fourier integral transform. Singular integral equations are obtained for each case and analytic solutions are determined in closed form for the case of constant loading. Exact singular elastic fields including the moments, effective shear force, and bulk stress components along the crack line for each case are presented in terms of the complete elliptical integrals. The stress intensity factors for in-plane stresses exhibit a usual inverse square-root singularity and depend on both surface and bulk material properties, while the intensity factors of the anti-plane shear stress and of the effective shear force admit an \(r^{-3/2}\) singularity, r being the distance from the closest crack tip. The influences of the material properties and the space between two cracks on fracture parameters are illustrated graphically. Surface phase with positive material properties has a shielding effect and that with negative material properties has an anti-shielding effect on crack growth.

Similar content being viewed by others

References

Choi S, Lee H, Ghaffari R, Hyeon T, Kim D-H (2016) Recent advances in flexible and stretchable bio-electronic devices integrated with nanomaterials. Adv Mater 28(22, SI):4203–4218

Wang C, Xia K, Wang H, Liang X, Yin Z, Zhang Y (2018) Advanced carbon for flexible and wearable electronics. Adv Mater 31(9):1801072

Wang M, Zhang R, Ilic R, Aksyuk V, Liu Y (2020) Frequency stabilization of nanomechanical resonators using thermally invariant strain engineering. Nano Lett 20(5):3050–3057

Makowski JD, Talghader JJ (2007) Surface heterostructure nanomechanical actuators with atomic resolution. Appl Phys Lett 90(18):183111

Cohen-Tanugi D, Grossman JC (2014) Mechanical strength of nanoporous graphene as a desalination membrane. Nano Lett 14(11):6171–6178

Tsuchiya T, Tabata O, Sakata J, Taga Y (1998) Specimen size effect on tensile strength of surface-micromachined polycrystalline silicon thin films. J Microelectromech Syst 7(1):106–113

Lachut MJ, Sader JE (2007) Effect of surface stress on the stiffness of cantilever plates. Phys Rev Lett 99(20):206102

Pan AF, Wang WJ, Mei XS, Zheng BX, Yanstate ZX (2016) Cracks growth behaviors of commercial pure titanium under nanosecond laser irradiation for formation of nanostructure-covered microstructures (with sub-5-mu m). Appl Surf Sci 387(30):1046–1053

Benzaid R, Chevalier J, Saddaoui M, Fantozzi G, Nawa M, Diaz LA, Torrecillas R (2008) Fracture toughness, strength and slow crack growth in a ceria stabilized zirconia-alumina nanocomposite for medical applications. Biomaterials 29(27):3636–3641

Yang F, Taggart DK, Penner RM (2009) Fast, sensitive hydrogen gas detection using single palladium nanowires that resist fracture. Nano Lett 9(5):2177–2182

Kim D-H, Kim Y-S, Wu J, Liu Z, Song J, Kim H-S, Huang YY, Hwang K-C, Rogers JA (2009) Ultrathin silicon circuits with strain-isolation layers and mesh layouts for high-performance electronics on fabric, vinyl, leather, and paper. Adv Mater 21(36):3703–3707

Zhuo XR, Kim JH, Beom HG (2016) Atomistic investigation of crack growth resistance in a single-crystal Al-nanoplate. J Mater Res 31(9):1185–1192

Baetens T, Pallecchi E, Thomy V, Arscott S (2018) Cracking effects in squashable and stretchable thin metal films on PDMS for flexible microsystems and electronics. Sci Rep 8:9492

Rogers JA, Someya T, Huang Y (2010) Materials and mechanics for stretchable electronics. Science 327(5973):1603–1607

Hu Z-L, Lee KY, Li X-F (2018) Crack in an elastic thin-film with surface effect. Int J Eng Sci 123:158–173

Hu Z-L, Yang Y, Li X-F (2021) Bending fracture of ultra-thin plates with surface elasticity containing a thickness-through crack. Int J Solids Struct 226–227:111093

Hu Z-L, Yang Y, Li X-F (2021) Singular elastic field induced by a rigid line inclusion in a thin nanoplate with surface elasticity. Int J Mech Sci 198:106386

Hu Z-L, Yang Y, Li X-F (2022) Singular elastic field induced by a rigid line adhering to a micro/nanoscale plate during bending. Appl Math Modell 108:567–584

Knowles JK, Wang N-M (1960) On the bending of an elastic plate containing a crack. J Math Phys 39(1–4):223–236

Sih GC, Paris PC, Erdogan F (1962) Crack-tip, stress-intensity factors for plane extension and plate bending problems. J Appl Mech 29(2):306–312

Zehnder AT, Hui C-Y (1994) Stress intensity factors for plate bending and shearing problems. J Appl Mech 61(3):719–722

Young MJ, Sun CT (1993) Cracked plates subjected to out-of-plane tearing loads. Int J Fract 60(1):1–18

Zucchini A, Hui CY, Zehnder AT (2000) Crack tip stress fields for thin, cracked plates in bending, shear and twisting: a comparison of plate theory and three-dimensional elasticity theory solutions. Int J Fract 104(4):387–407

Liu CT, Jiang CP (2014) Fracture mechanics for plates and shells. National Military Industry Press, Arlington

Nanthakumar SS, Lahmer T, Zhuang XY, Zi G, Rabczuk T (2016) Detection of material interfaces using a regularized level set method in piezoelectric structures. Inv Prob Sci Eng 24(1):153–176

Anitescu C, Atroshchenko E, Alajlan N, Rabczuk T (2019) Artificial neural network methods for the solution of second order boundary value problems. Comput Mater Cont 59(1):345–359

Shiue S-T, Zhang T-Y, Lee S (1995) Elastic analysis of an edge dislocation and two collinear cracks of different length. Int J Fract 68(4):333–350

Li XF (2002) Closed-form solution for a piezoelectric strip with two collinear, cracks normal to the strip boundaries. Eur J Mech A Solids 21(6):981–989

Zhou Z-G, Wu L-Z, Du S-Y (2007) Non-local theory solution of two mode-i collinear cracks in the piezoelectric materials. Mech Adv Mater Struct 14(3):191–201

Chang D, Kotousov A (2012) A strip yield model for two collinear cracks in plates of arbitrary thickness. Int J Fract 176(1):39–47

Bhargava RR, Jangid K, Verma PR (2015) Two semi-permeable equal collinear cracks weakening a piezoelectric plate: a study using complex variable technique. Z Angew Math Mech 95(1):66–76

Gurtin ME, Murdoch AI (1975) A continuum theory of elastic material surfaces. Arch Ration Mech Anal 57(4):291–323

Wang X, Schiavone P (2015) Interaction between an edge dislocation and a crack with surface elasticity. J Appl Mech 82(2):021006

Muskhelishvili I, Nikola, Radok JRM (2008) Singular integral equations: boundary problems of function theory and their application to mathematical physics. Courier Corporation

Pishkenari HN, Yousefi FS, Taghibakhshi A (2018) Determination of surface properties and elastic constants of FCC metals: a comparison among different EAM potentials in thin film and bulk scale. Mater Res Express 6(1):015020

Miller RE, Shenoy VB (2000) Size-dependent elastic properties of nanosized structural elements. Nanotechnology 11(3):139–147

Shenoy VB (2005) Atomistic calculations of elastic properties of metallic fcc crystal surfaces. Phys Rev B 71(9):094104

Mi C, Jun S, Kouris DA, Kim SY (2008) Atomistic calculations of interface elastic properties in noncoherent metallic bilayers. Phys Rev B 77(7):075425

Ho DT, Park S-D, Kwon S-Y, Park K, Kim SY (2014) Negative Poisson’s ratios in metal nanoplates. Nat Commun 5:3255

Ayatollahi MR, Shadlou S, Shokrieh MM (2011) Fracture toughness of epoxy/multi-walled carbon nanotube nano-composites under bending and shear loading conditions. Mater Des 32(4):2115–2124

Castellanosgomez A, Poot M, Steele GA, Der Zant HSJV, Agrait N, Rubiobollinger G (2012) Elastic properties of freely suspended MoS2 nanosheets. Adv Mater 24(6):772–775

Srivastava AK, Gupta V, Yerramalli CS, Singh A (2019) Flexural strength enhancement in carbon-fiber epoxy composites through graphene nano-platelets coating on fibers. Compos Part B 179:107539

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Nos. 11672336 and 12072374), the Natural Science Foundation of Hunan Province (No. 2020JJ4106), and the Fundamental Research Funds for Graduate Student Innovation Project of Hunan Province (No. CX20200217).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix A

Appendix A

It is helpful to express the surface strain components in terms of surface stress components. For the present study, in the case of \(\sigma _{0}=0\), we have

After some calculations, the expressions for the surface strains \(\varepsilon _{xx}^{s}\) and \(\varepsilon _{yy}^{s}\) are expressed as

Therefore, the relationships between a pair of the surface Lame constants \(\lambda ^{s}\) and \(\mu ^{s}\) and a pair of surface Young’s modulus \(E_{s}\) and surface Poisson’s ratio \(\nu _{s}\) are written as follows

It is easily found that the above relationships are different from their classical counterparts. Furthermore, the surface strain can be given by

Obviously, if requiring the surface Lame constants to be positive, we find that surface Poisson’s ratio ranges between \(-1\) and 1. If permitting negative surface Lame constants (see e.g., [37, 38]), surface Poisson’s ratio exceeds the above-stated range. In fact, such values of surface Poisson’s ratio have been reported for nanoplates in [39].

Rights and permissions

About this article

Cite this article

Hu, ZL., Yang, Y., Zhang, XY. et al. Bending of a nanoplate with strain-dependent surface stress containing two collinear through cracks. Meccanica 57, 1937–1954 (2022). https://doi.org/10.1007/s11012-022-01553-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11012-022-01553-1