Abstract

This article deals with the mathematical derivation and the validation over benchmark examples of a numerical method for the solution of a finite-strain holonomic (rate-independent) Cosserat plasticity problem for materials, possibly with microstructure. Two improvements are made in contrast to earlier approaches: First, the micro-rotations are parameterized with the help of an Euler–Rodrigues formula related to quaternions. Secondly, as main result, a novel two-pass preconditioning scheme for searching the energy-minimizing solutions based on the limited memory Broyden–Fletcher–Goldstein–Shanno quasi-Newton method is proposed that consists of a predictor step and a corrector-iteration. After outlining the necessary adaptations to the model, numerical simulations compare the performance and efficiency of the new and the old algorithm. The proposed numerical model can be effectively employed for studying the mechanical response of complicated materials featuring large size effects.

Similar content being viewed by others

References

Lakes RS (1991) Experimental micro mechanics methods for conventional and negative Poisson’s ratio cellular solids as Cosserat continua. J Eng Mater Technol 113:148–155

Bardella L, Paggi M, Vena P (2018) Special issue on ‘Recent advances on the mechanics of materials’. Meccanica 53(3):509–510

Rueger Z, Lakes RS (2017) Strong Cosserat elastic effects in a unidirectional composite. Zeitschrift für Angewandte Mathematik und Physik (ZAMP) 68:54

Trovalusci P, Pau A (2014) Derivation of microstructured continua from lattice systems via principle of virtual works: the case of masonry-like materials as micropolar, second gradient and classical continua. Acta Mechanica 225(1):157–177

Leonetti L, Greco F, Trovalusci P, Luciano R, Masiani R (2018) A multiscale damage analysis of periodic composites using a couple-stress/Cauchy multidomain model: application to masonry structures. Compos Part B: Eng 141:50–59

Trovalusci P, Varano V, Rega G (2010) A generalized continuum formulation for composite microcracked materials and wave propagation in a bar. J Appl Mech Trans ASME 77(6):061002

Trovalusci P, Augusti G (1998) A continuum model with microstructure for materials with flaws and inclusions. Journal De Physique. IV: JP 8(8):383–390

Minga E, Macorini L, Izzuddin BA (2018) A 3D mesoscale damage-plasticity approach for masonry structures under cyclic loading. Meccanica 53(7):1591–1611

Lakes RS (1995) Experimental methods for study of Cosserat elastic solids and other generalized continua. In: Mühlhaus H, Wiley J (eds) Continuum models for materials with micro-structure. New York 1:1–22

Mindlin RD (1964) Micro-structure in linear elasticity. Arch Ration Mech Anal 16:51–78

Eringen AC (1999) Microcontinuum field theories. Springer, New York

Cosserat E, Cosserat F (1909) Théorie des corps déformables, Librairie Scientifique A. Hermann et Fils, Paris [English version: Theory of deformable bodies, NASA TT F-11 561 (1968)]

Maugin GA (2010) Mechanics of generalized continua—One hundred years after the cosserats. Springer, Berlin

Neff P (2006) A finite-strain elastic-plastic Cosserat theory for polycrystals with grain rotations. Int J Eng Sci 44:574–594

Ask A, Forest S, Appolaire B, Ammar K, Salmand OU (2018) A Cosserat crystal plasticity and phase field theory for grain boundary migration. J Mech Phys Solids 115:167–194

Corradi L, Genna F (1990) Kinematic extremum theorems for holonomic plasticity. Int J Plast 6(1):63–82

Corradi L, Genna F, Annovazzi L (1991) Holonomic Versus Rate Relations in Plasticity. In: Del Piero G, Maceri F, (eds) Unilateral problems in structural analysis IV. International Series of Numerical Mathematics/Internationale Schriftenreihe zur Numerischen Mathematik—Série Internationale d’Analyse Numérique, vol 101, Birkhäuser Basel

Gidoni P, DeSimone A (2017) Stasis domains and slip surfaces in the locomotion of a bio-inspired two-segment crawler. Meccanica 52(3):587–601

Amendola A, Smith CJ, Goodall R, Auricchio F, Feo L, Benzoni G, Fraternali F (2016) Experimental response of additively manufactured metallic pentamode materials confined between stiffening plates. Compos Struct 142:254–262

Fraternali F, Carpentieri G, Montuori R, Amendola A, Benzoni G (2015) On the use of mechanical metamaterials for innovative seismic isolations systems. In: Proceedings of the 5th ECCOMAS thematic conference on computational methods in structural dynamics and earthquake engineering (COMPDYN 2015), pp 349–358

Fabbrocino F, Farina I, Amendola A, Feo L, Fraternali F (2016) Optimal design and additive manufacturing of novel reinforcing elements for composite materials. In: Proceedings of the 7th European congress on computational methods in applied sciences and engineering (ECCOMAS 2016) 1:1893–1908

Amendola A, Fabbrocino F, Feo L, Auricchio F, Fraternali F (2016) Dependence of the mechanical properties of pentamode materials on the lattice microstructure. Proceedings of the 7th European Congress on Computational Methods in Applied Sciences and Engineering (ECCOMAS 2016), 1, 2134–2150

Trovalusci P (2014) Molecular approaches for multifield continua: origins and current developments. CISM international centre for mechanical sciences, courses and lectures 556:211–278

Fantuzzi N, Trovalusci P, Dharasura S (2019) Mechanical behaviour of anisotropic composite materials as micropolar continua. Frontiers 59(6):1–11

Nocedal J (1980) Updating quasi-Newton matrices with limited storage. Math Comput 35:773–782

Nocedal J (1989) On the limited memory method for large scale optimization. Math Program B 45:503–528

Blesgen T (2015) On rotation deformation zones for finite-strain Cosserat plasticity. Acta Mechanica 226:2421–2434

Pusztai T, Bortel G, Granasy L (2005) Phase field theory of polycrystalline solidification in three dimensions. Europhys Lett 71(1):131–137

Alaimo A, Artale V, Milazzo C, Ricciardello A (2013) Comparison between Euler and Quaternion parametrization in UAV dynamics. AIP Conf Proc 1558:1228

Dargham R, Sayouti A, Medromi H (2015) Euler and Quaternion parameterization in VTOL UAV dynamics with test model efficiency. Int J Appl Inf Syst (IJAIS) 9(8):25–28

Euler L (1755) Nova methodus motum corporum rigidorum determinandi, novi commentari. Acad Imp Petrop 20:208–238

Rodrigues O (1840) Des lois géométriques qui régissent les déplacements d’un systéme solide dans l’espace, et de la variation des coordonnées provenant de ces déplacements considéres indépendamment des causes qui peuvent les produire. J Math 5:380–440

Hamilton WR (1844) On quaternions; or on a new system of imaginaries in algebra. Philos Mag 3:489–495

Andrei N (2007) A scaled BFGS preconditioned conjugate gradient algorithm for unconstrained optimization. Appl Math Lett 20:645–650

Erway J, Marcia RF (2012) Solving limited-memory BFGS systems with generalized diagonal updates. In: Proceedings world congress on engineering

De Sterck H, Howse AJM (2018) Nonlinearly preconditioned L-BFGS as an acceleration mechanism for alternating least squares, with application to tensor decomposition. Numer Linear Algebra Appl 25:1–31

Marjugi SM, Leong WJ (2013) Diagonal Hessian approximation for limited memory Quasi-Newton via variational principle. J Appl Math. https://doi.org/10.1155/2013/523476

Jiang L, Byrd R.H, Eskow E, Schnabel R.B (2004) A preconditioned L-BFGS algorithm with application to molecular energy minimization, Technical Report CU-CS-982-04, University of Colorado

Reddy BD, Martin JB, Griffin TB (1987) Extremal paths and holonomic constitutive laws in elastoplasticity. Quart Appl Math 45(3):487–502

Ortiz M, Stainier L (1999) The variational formulation of viscoplastic constitutive updates. Comput Methods Appl Mech Eng 171(3–4):419–444

Fonseca I, Francfort GA (1995) Relaxation in BV versus quasiconvexification in \(W^{1, p}\); a model for the interaction between fracture and damage. Calc Var 3(4):407–446

Gurtin ME (2002) A gradient theory of single-crystal viscoplasticity that accounts for geometrically necessary dislocations. J Mech Phys Solids 50:5–32

Carstensen C, Hackl K, Mielke A (2002) Non-convex potentials and microstructures in finite-strain plasticity. Proc R Soc Lond A 458:3275–3289

Panteghini A, Bardella L (2018) On the role of higher-order conditions in distortion gradient plasticity. J Mech Phys Solids 118:293–321

Schatz F, Silveira JL (2018) Variational principles for shakedown analysis of materials with internal rotation. Meccanica 53(4–5):1093–1104

Borokinni AS, Fadodun O, Akinola AP (2018) Distortion-gradient plasticity theory for an isotropic body in finite deformation. Meccanica 53(11–12):3145–3155

Kessel S (1964) Lineare Elastizitätstheorie des anisotropen Cosserat–Kontinuums, Abhandlung Braunschweigische Wiss. Gesell 16:1–22

Blesgen T (2013) Deformation patterning in Cosserat plasticity. Model Simul Mater Sci Eng 21:035001

Han W, Reddy D (1999) Plasticity. Mathematical theory and numerical analysis. Springer, Berlin

Lubliner J (2008) Plasticity Theory. Dover Publications, Mineola

Ortiz M, Repetto E (1999) Nonconvex energy minimization and dislocation structures in ductile single crystals. J Mech Phys Solids 47:397–462

Weber G, Anand L (1990) Finite deformation constitutive equations and a time integration procedure for isotropic, hyperelastic-viscoplastic solids. Comput Methods Appl Mech Eng 79:173–202

Crumbach M, Goerdeler M, Gottstein G (2006) Modelling of recrystallisation textures in aluminium alloys: I. Model set-up and integration. Acta Materialia 54:3275–3289

Blesgen T, Luckhaus S (2006) The dynamics of transition layers in solids with discontinuous chemical potentials. Math Methods Appl Sci 29:525–536

Blesgen T (2014) Deformation patterning in three-dimensional large-strain Cosserat plasticity. Mech Res Commun 62(C):37–43

Hamilton WR (1844) On quaternions, The London, Edinburgh and Dublin Philosophical Magazine and Journal of Science 25:10–13

Ebbinghaus H-D, Hermes H, Hirzebruch F, Koecher M, Mainzer K, Neukirch J, Prestel A, Remmert R (1991) Numbers. Springer, Berlin

Dam E.B, Koch M, Lillholm M (1998) Quaternions, interpolation and animation, Technical Report DIKU-TR-98/5, University of Copenhagen

Blesgen T (2017) A variational model for dynamic recrystallization based on Cosserat plasticity. Compos Part B 115:236–243

Kuipers JB (1999) Quaternions and Rotation Sequences: a primer with Applications to Orbits, Aerospace, and Virtual Reality. Princeton University Press, Princeton

Lang H, Linn J (2009) Lagrangian field theory in space and time for geometrically exact Cosserat rods. Reports of Fraunhofer ITWM 150

Liu DC, Nocedal J (1989) On the limited memory BFGS method for large scale optimization methods. Math Prog 45:503–528

Byrd RH, Nocedal J, Schnabel RB (1994) Representations of quasi-Newton matrices and their use in limited-memory methods. Math Program 63:129–156

Oren SS, Luenberger DG (1974) Self-scaling variable metric (SSVM) algorithms I: criteria and sufficient conditions for scaling a class of algorithms. Manag Sci 20:845–862

Dongarra JJ, Bunch JR, Moler CB, Stewart GW (1979) LINPACK users’ guide. SIAM, Philadelphia

Shoemake K (1985) Animating Rotations with Quaternion Curves. In B.A. Barsky: Computer Graphics (SIGGRAPH 85 Proceedings) 19:245–254

Francfort GA, Giacomini A, Marigo J-J (2016) The elasto-plastic exquisite corpse: a suquet legacy. J Mech Phys Solids 97:125–139

Acknowledgements

Part of this article was written while TB visited the Hausdorff Research Institute for Mathematics (HIM), University of Bonn, in 2019. This visit was supported by the HIM. TB gratefully acknowledges both this support and the hospitality of HIM. AA gratefully acknowledges financial support from the Italian Ministry of Education, University and Research (MIUR) under the ‘Departments of Excellence’ Grant L.232/2016.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1: List of symbols

- \(A\!:\!B\) :

-

Tensor product of A, B, below (6)

- \({{\varvec{u}}}\!\cdot \!{{\varvec{v}}}\) :

-

Inner product of \({{\varvec{u}}}\), \({{\varvec{v}}}\in {\mathbb {R}}^3\)

- \({\text {sym}}(\sigma )\) :

-

Symmetric part of a tensor \(\sigma\) (4)

- \({\text {skw}}(\sigma )\) :

-

Skew-symmetric part of \(\sigma\) (4)

- \(\mathrm {tr}(\sigma )\) :

-

Trace of tensor \(\sigma\)

- \(\sigma ^{ T}\) :

-

Transpose of \(\sigma\); \(R^{ T}\!=\!R^{-1}\) for \(R\!\in \!{\mathrm {SO}}(3)\)

- \(\Vert \cdot \Vert\) :

-

Frobenius matrix norm (4)

- \(|\cdot |\) :

-

Euclidean vector norm in \({\mathbb {R}}^4\) (33)

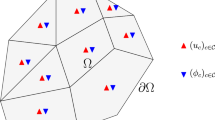

- \(\varOmega \subset {\mathbb {R}}^3\) :

-

Reference domain, undeformed solid

- (x, t):

-

Space and time coordinates

- \(\varphi\) :

-

Deformation vector of the solid (3)

- \(F\!=\!D\varphi\) :

-

Deformation tensor (3)

- \(F_{{\mathrm {e}}}\) :

-

Elasticity tensor (3)

- \(F_{{\mathrm {p}}}\) :

-

Plasticity tensor (3)

- \(R_{{\mathrm {\!e}}}\) :

- \(U_{{\mathrm {\!e}}}\) :

-

(right) stretching tensor (3)

- \(K_{{\mathrm {\!e}}}\) :

-

(right) curvature tensor (39)

- \({\mathbb {I}}\) :

-

Identity tensor, \(({\mathbb {I}})_{kl}=(\delta _{kl})_{kl}\) (10)

- \(\alpha\) :

-

Euler angle parameterization of \(R_{{\mathrm {\!e}}}\) (1)

- \(\gamma\) :

-

Single-slip parametrization of \(F_{{\mathrm {p}}}\) (10)

- q :

-

Quaternion parameterization of \(R_{{\mathrm {\!e}}}\) (2)

- \(q_D\) :

-

Dirichlet boundary values of q (8)

- \({\overline{q}}\) :

-

Conjugate of q (33)

- \({\mathscr {E}}\) :

-

Mechanical energy (13)

- \(h>0\) :

-

Discrete (fixed) time step (13)

- \(\gamma ^0\) :

-

Values of \(\gamma\) at old time t (12)

- \(\kappa ^0\) :

-

Values of \(\kappa\) at old time t (12)

- \(\kappa\) :

-

Dislocation density (12)

- \(V(\kappa )\) :

-

Dislocation energy (6)

- \(W_{{\mathrm {st}}}\) :

-

Stretching energy (4)

- \(W_{{\mathrm {c}}}\) :

-

Curvature energy (5)

- X :

-

Back stress (dual variable to \(F_{{\mathrm {p}}}\)) (9),

- \(\xi\) :

-

Hardening (dual variable to \(\kappa\)) (9)

- \(f_{{\mathrm {ext}}}\) :

-

External volume forces (13)

- \(M_{{\mathrm {ext}}}\) :

-

External volume couples (13)

- \(\sigma _Y\) :

-

Yield stress (13)

- \(Q^*\) :

-

Dissipated energy (11)

- \({{\varvec{m}}}\) :

-

Slip vector (10)

- \({{\varvec{n}}}\) :

-

Slip normal (10)

- \(\rho >0\) :

-

Dislocation energy constant (13)

- \(g_{_D}\) :

-

Dirichlet boundary values of \(\varphi\) (8)

- \(\varepsilon >0\) :

-

Regularization of \(|\cdot |\), Remark 1

- \(\varLambda >0\) :

-

Lagrange parameter to \(|q|^2=1\) (13)

- \(\lambda\), \(\mu\):

-

Lamé parameters (4)

- \(\mu _c\) :

-

Cosserat couple modulus (4)

- \(L_c\) :

-

Internal length scale (5)

- \(\mu _2\) :

-

Parameter \(\mu\) scaled by \(L_c^2\) (5)

- \(\varepsilon _0\) :

-

Stop/precision parameter (19)

- \(d_1,d_2,d_3\) :

- \(\eta _1,\eta _2,\eta _3\) :

-

Points on the numerical mesh (14)

- \(N_{IJK}\) :

- \(\beta (t)\) :

Appendix2: Use of quaternions in the Euler–Rodrigues formula

Following the classical notation in [56, 57], let

denote the space of quaternions, where the quaternion imaginary units satisfy \({{\varvec{i}}}^2={{\varvec{j}}}^2={{\varvec{k}}}^2={{\varvec{i}}}{{\varvec{j}}}{{\varvec{k}}}=-1\). Let

be the space of pure quaternions and

The set \({\mathbb {H}}\) is equipped with the multiplication (for \(p,q\in {\mathbb {H}}\))

where \({\widehat{p}}\cdot {\widehat{q}}:=p_1q_1+p_2q_2+p_3q_3\) specifies as above the inner product and \({\widehat{p}}\times {\widehat{q}}\) the vector product of \({\mathbb {R}}^3\), respectively. In general, \(pq\not =qp\), so \({\mathbb {H}}\) is an associative, non-commutative algebra. Let \({\overline{q}}:=q_0-{\widehat{q}}\) be the conjugate of q and

be the modulus of q. By Formula (32), \(q\in {\mathbb {H}}^*:={\mathbb {H}}{\setminus }\{0\}\) possesses the multiplicative inverse \(q^{-1}=\frac{{\overline{q}}}{|q|^2}\). Let

be the Lie algebra of \({\mathrm {SO}}(3)\). The alternating skew tensor\(\varepsilon :{\mathbb {H}}_{{\mathrm {p}}}\rightarrow {\mathrm {so}}(3)\) is defined by

Evidently,

By direct inspection, it is straightforward to verify that for every \(q\in S^3\)

defines a rotation in \({\mathrm {SO}}(3)\). Using (32), this leads to

Plugging in the above definitions, this coincides with Formula (2).

The mapping \(R_{{\mathrm {\!e}}}\) thus introduced has the properties

and is therefore an algebra-homomorphism. It is a double cover of \({\mathrm {SO}}(3)\), especially it is non-unique, since

In comparison, the parameterization (1) breaks down for \(\alpha _2=\frac{\pi }{2}\), in which case \(\alpha _1\) and \(\alpha _3\) denote a rotation around the same axis. In summary, both (2) and (1) set up rivaling charts on the manifold \({\mathrm {SO}}(3)\) which have certain disadvantages when used globally.

Eular angles may be more direct to interpret and require one parameter less than quaternions. Nevertheless, the quaternion description is preferable here, as is discussed in Sect. 4.

Formula (2) can be used to interpolate between rotations and allows to introduce a distance in \({\mathrm {SO}}(3)\), see, e.g. [58]. This is a prerequisite to studying surface energies between grains or particles of different orientations [59].

For \(x\in {\mathbb {R}}^3\) and a quaternion field \(q=q(x)\), the m-th material curvature vector or Darboux vector is given by

The following lemma computes the derivatives of \(R_{{\mathrm {\!e}}}(q)\) and \(K_{{\mathrm {\!e}}}(q)\) in \({\mathbb {H}}\) with \(|q|=1\).

Lemma 1

(Lie Derivatives of \(R_{{\mathrm {\!e}}}\) and \(K_{{\mathrm {\!e}}}^m\)) Let\(q=q(x):{\mathbb {R}}^3\rightarrow S^3\)and\(1\le l,m\le 3\). Then

Proof

An elementary proof of (40) can be found in [60], Chapter 11. The following proof is a modification of an argument in [61]. Let \(v\in {\mathbb {R}}^3\simeq {\mathbb {H}}_{{\mathrm {p}}}\) and let \(w\in {\mathbb {R}}^3\) denote various changing vectors. Then it holds

As this is true for every \(v\in {\mathbb {R}}^3\simeq {\mathbb {H}}_{{\mathrm {p}}}\), this shows

Multiplication with \(R_{{\mathrm {\!e}}}(q)\) from the left yields (40).

In order to show (41), multiplying (39) with q from the left yields

Consequently,

or equivalently

Multiplication of this identity with \({\overline{q}}\) from the left leads to

With (39), this shows (41). \(\square\)

Applying the results of Lemma 1 to \(W_{{\mathrm {c}}}\), it holds by Eqns. (40) and (34),

For the first derivative, using (39) and (41), this results in

Rights and permissions

About this article

Cite this article

Blesgen, T., Amendola, A. Mathematical analysis of a solution method for finite-strain holonomic plasticity of Cosserat materials. Meccanica 55, 621–636 (2020). https://doi.org/10.1007/s11012-019-01006-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11012-019-01006-2