Abstract

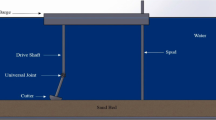

In the view of fluid-structure interactions and rotor dynamics, this paper models the lateral vibration of a vertical downward rotating elastic drill string conveying mud subjected to supporting stabilizers, bit torque and longitudinal thrust. The dynamic model involves the rotational inertia of the drill string tube cross section, the gyroscopic effect caused by rotation, the damping due to friction with the surrounding fluid, the gravity force and mud buoyancy. Damped natural frequency, stability and resonance of the drill string system are determined by quadratic eigenvalue problem and investigated at influences of the stabilizer, rotational angular speed, mud flowing velocity, bit torque and thrust. As a result, the drill string can lose stability both at simultaneous and separate influences of the mud conveying, bit torque and thrust, whereas the rotation, stabilizer and gravity of the drill string can improve system stability; the rotational angular speed causing system resonance decreases with the increase of the mud flowing velocity, bit torque and thrust.

Similar content being viewed by others

Abbreviations

- A m :

-

tube bore area of the drill string

- A t :

-

area of the tube wall cross section

- c :

-

visco-elastic damping coefficient

- \(c_{j}^{\mathrm{s}}\) :

-

damping coefficient

- E :

-

Young’s modulus of the drill string material

- g, G :

-

acceleration of gravity

- I m :

-

area moment of inertia of the tube bore

- I t :

-

area moment of inertia of the tube wall cross section

- j :

-

the j-th stabilizer

- J :

-

stabilizer number

- \(k_{j}^{\mathrm{s}}\) :

-

stiffness coefficient

- L :

-

total length of the drill string

- p m :

-

mud pressure in the tube

- P :

-

longitudinal thrust on bit

- r i, r o :

-

inner and outer diameter of the drill string tube

- t :

-

time

- T :

-

torque on bit

- v :

-

dimensionless mud flowing velocity

- v c :

-

dimensionless critical mud flowing velocity

- V :

-

mud flowing velocity in the tube

- w, w u , w v :

-

elastic displacement

- x :

-

longitudinal coordinate

- \(x_{j}^{\mathrm{s}}\) :

-

stabilizer location

- γ :

-

dimensionless thrust on bit

- γ c :

-

dimensionless critical bit longitudinal thrust

- ε :

-

dimensionless torque on bit

- ε c :

-

dimensionless critical bit torque

- ζ :

-

dimensionless rotating angular speed

- ζ r :

-

resonant rotational angular speed

- η :

-

coefficient of internal dissipation

- η k :

-

dimensionless coefficient of internal dissipation

- η m :

-

dimensionless visco-elastic damping coefficient

- \(\eta ^{\mathrm{s}} _{j},\ \eta _{\mathrm{s}}\) :

-

dimensionless damping coefficient

- \(\kappa ^{\mathrm{s}} _{j},\ \kappa _{\mathrm{s}}\) :

-

dimensionless stiffness coefficient

- λ :

-

eigenvalue

- ρ m :

-

mud density

- ρ t :

-

density of the drill string material

- τ :

-

dimensionless time

- ω 0 :

-

first damped natural frequency of load-free drill string system

- Ω :

-

drill string rotating angular speed

References

Gulyayev VI, Hudoliy SN, Glushakova OV (2011) Simulation of torsion relaxation auto-oscillations of drill string bit with viscous and Coulombic friction moment models. Proc Inst Mech Eng, Proc, Part K, J Multi-Body Dyn 225:139–152

Païdoussis MP, Luu TP, Prabhakar S (2008) Dynamics of a long tubular cantilever conveying fluid downwards, which then flows upwards around the cantilever as a confined annular flow. J Fluids Struct 24:111–128

Païdoussis MP (1998) Fluid-structure interactions: slender structures and axial flow, vol 1. Academic Press, London

Modarres-Sadeghi Y, Païdoussis MP (2009) Nonlinear dynamics of extensible fluid-conveying pipes, supported at both ends. J Fluids Struct 25:535–543

Qian Q, Wang L, Ni Q (2008) Vibration and stability of vertical upward-fluid-conveying pipe immersed in rigid cylindrical channel. Acta Mech Solida Sin 21:331–340

Vaz MA, Patel MH (1995) Analysis of drill strings in vertical and deviated holes using the Galerkin technique. Eng Struct 17:437–442

Gulyayev VI, Gaidaichuk VV, Solovjov IL, Gorbunovich IV (2009) The buckling of elongated rotating drill strings. J Pet Sci Eng 67:140–148

Gulyaev VI, Gaidaichuk VV, Solov’ev IL, Gorbunovich IV (2010) Quasistatic bifurcation states of super-deep vertical drill strings. J Min Sci 46:546–553

Spanos PD, Chevallier AM, Politis NP (2002) Nonlinear stochastic drill-string vibrations. Trans ASME J Vib Acoust 124:512–518

Genta G (2005) Dynamics of rotating systems. Springer, New York

Gulyayev VI, Tolbatov EY (2002) Forced and self-excited vibrations of pipes containing mobile boiling fluid clots. J Sound Vib 257:425–437

Pei YC, Lu H, Chatwin C (2010) Dynamics of a rotating shaft-disc under a periodic axial force. Proc Inst Mech Eng, Proc, Part K, J Multi-Body Dyn 224:211–219

Przybyłowicz PM (2003) Active stabilization of a rotating shaft transmitting static torque. Meccanica 38:763–770

Raffa FA, Vatta F (1999) Gyroscopic effects analysis in the Lagrangian formulation of rotating beams. Meccanica 34:357–366

Raffa FA, Vatta F (2007) Dynamic instability of axially loaded shafts in the Mathieu map. Meccanica 42:547–553

Shahgholi M, Khadem SE (2013) Resonances of an in-extensional asymmetrical spinning shaft with speed fluctuations. Meccanica 48:103–120

Cossalter V, Lot R, Massaro M (2011) An advanced multibody code for handling and stability analysis of motorcycles. Meccanica 46:943–958

Sorge F, Cammalleri M (2012) On the beneficial effect of rotor suspension anisotropy on viscous-dry hysteretic instability. Meccanica 47:1705–1722

Allahverdizadeh A, Mahjoob MJ, Eshraghi I, Asgharifard-S P (2012) Effects of electrorheological fluid core and functionally graded layers on the vibration behavior of a rotating composite beam. Meccanica 47:1945–1960

Gürgöze M, Zeren S (2011) The influences of both offset and mass moment of inertia of a tip mass on the dynamics of a centrifugally stiffened visco-elastic beam. Meccanica 46:1401–1412

Amer YA, Hegazy UH (2012) Chaotic vibration and resonance phenomena in a parametrically excited string-beam coupled system. Meccanica 47:969–984

Acknowledgements

This work was supported by the Chinese Government’s Executive Program for Exploring the Deep Interior Beneath the Chinese Continent—Instrumentation Development for Deep Continental Scientific Drilling (Sinoprobe-09-05).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pei, YC., Sun, YH. & Wang, JX. Dynamics of rotating conveying mud drill string subjected to torque and longitudinal thrust. Meccanica 48, 2189–2201 (2013). https://doi.org/10.1007/s11012-013-9733-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11012-013-9733-8