Abstract

The paper proposes a model for a cold rolling mill process in the full-film regime that uses lubricant emulsion sprayed on at the entrance of the strip. The aim of the model is to forecast the reduction of strip thickness versus the flow rate of lubricant given the other operation parameters. The model includes strip plastic deformation, lubricant flow and lubricant viscosity depending on pressure. The mathematical problem is a free boundary one and a numerical procedure, applied to an industrial plant, is presented with some results.

Similar content being viewed by others

Abbreviations

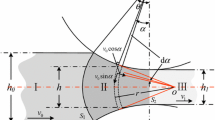

- h(x):

-

Lubricant film thickness

- h 0 :

-

Inlet lubricant film thickness

- p(x):

-

Normal pressure of lubricant film acting on the strip surface

- R :

-

Roll radius

- S 1 :

-

Inlet strip thickness

- S 2 :

-

Outlet strip thickness

- u 1 :

-

Horizontal component of the strip speed

- u 1,0 :

-

Horizontal component of the strip speed in the inlet zone

- u 1,f :

-

Horizontal component of the strip speed in the outlet zone

- u 2 :

-

Horizontal component of the roll speed

- v 1 :

-

Vertical component of the strip speed

- v 2 :

-

Vertical component of the roll speed

- x :

-

Generic abscissa

- x 1 :

-

Abscissa of the point in which the plastic deformation takes place

- y :

-

Generic ordinate

- y 1,0 :

-

Strip ordinate in the inlet zone

- y 1,f :

-

Strip ordinate in the outlet zone

- y 1(x):

-

Strip profile ordinate

- y 2(x):

-

Roll profile ordinate

- γ :

-

Viscosity coefficient in Barus law

- μ :

-

Lubricant viscosity

- μ 0 :

-

Lubricant viscosity corresponding to a pressure p=0

- σ s :

-

Material yield stress

- σ x :

-

Normal horizontal stress

- σ Y :

-

Normal vertical stress

- τ :

-

Tangential stress acting on the strip surface

- ω :

-

Angular roll speed

- Q :

-

Lubricant flow rate

- P * :

-

Pressure relative to material yield stress

- X * :

-

Dimensionless abscissa X *=x/x 1

References

Orowan E (1943) The calculation of roll pressure in hot and cold flat rolling. Proc Inst Mech Eng 150:140–167

Cheng HS (1966) Plasto-hydrodynamic lubrication. In: Friction and lubrication in metal processing. ASME, New York, pp 69–89

Wilson WRD, Walowit JA (1971) An isothermal hydrodynamic lubrication theory for slip rolling with front and back tension. In: Tribology convention. Institution of Mechanical Engineers, London, pp 164–172

Bedi DS, Hillier MJ (1968) Hydrodynamic model for strip cold rolling. Proc Inst Mech Eng 182(1):158–162

Avitzur B, Grossman G (1972) Hydrodynamic lubrication in the rolling of thin strips. ASME J Eng Ind Ser B 94(1):317–328

Wilson WRD, Murch LE (1976) A refined model for the hydrodynamic lubrication of strip rolling. ASME J Lubr Technol 98:426–432

Dow TA, Kannel JW, Bupara SS (1975) A hydrodynamic lubrication theory for strip rolling including thermal effects. ASME J Lubr Technol 97:4–12

Sa C-Y, Wilson WRD (1993) Full film lubrication of strip rolling. ASME J Tribol 13:1–8

Szeri AZ, Wang SH (2004) An elasto-pasto-hydrodynamic model of strip rolling with oil/water emulsion lubricant. Elsevier Tribol Int 37:169–176

Hamrock BJ (1994) Fundamentals of fluid film lubrication. McGraw–Hill, New York

Dowson D (1998) Modelling of elastohydrodynamic lubrication of real solids by real lubricants. Meccanica 33:47–58

Szeri S, Snyder V (2006) Convective inertia effects in wall-bounded thin film flows. Meccanica 41:473–482

Mulone G, Salemi F (1983) On the existence of hydrodynamic motion in a domain with free boundary type conditions. Meccanica 18:136–144

Roberts WL (1980) Flat processing of steel. Dekker, New York

Shampine LF, Gordon MK (1975) Computer solution of ordinary differential equations: the initial value problem. Freeman, San Francisco

Booser ER (1997) Tribology data handbook. CRC Press, Boca Raton

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Valigi, M.C., Malvezzi, M. Cold rolling mill process: a numerical procedure for industrial applications. Meccanica 43, 1–9 (2008). https://doi.org/10.1007/s11012-007-9085-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11012-007-9085-3