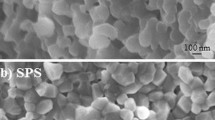

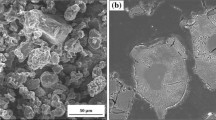

Initiation of self-expanding high-temperature synthesis (SHS) in the Al–Ti–C system in the process of spark plasma sintering (SPS) of specimens allows obtaining a material with high density, which contains MAX-phases. A simple rheological theory has been developed, which can describe SHS and SPS processes under certain conditions. Within the framework of this model, the processes of pressing and extrusion at uniaxial pressure are considered. The dependence of the relative density of the powder mixture on time is scaled by the factor of the ratio of pressure to the viscosity of the invariant base of the material. Analytical time dependences of the plunger speed and sample height, as well as the time required to achieve the specified value of the relative density of the Al–Ti–C material, which allows us to predict and analyze the compression of powder mixtures in the SPS process were obtained.

Similar content being viewed by others

References

V. E. Ovcharenko, and O. V. Lapshyn, “Evolution of the grain structure during the extrusion of an intermetallic compound Ni3Al in the process of high-temperature synthesis under pressure. I. Mathematical model,” Fizika i Khimiya Obrabotki Materialov [in Ukrainian], 3, 76–83 (2007).

V. V. Skorokhod, Rheological Foundations of the Theory of Sintering [in Russian], Naukova Dumka, Kyiv (1972).

V. M. Gorokhov, and M. S. Kovalchenko, “Modern ideas about the mechanism of behavior of Powder Materials during Hot Pressing,” in: Rheological Models and Deformation Processes of Porous and Powder Composite Materials [in Russian], Naukova Dumka, Kyiv (1985), pp. 126–135.

L. M. Buchatskii, A. M. Stolin, and S. I. Khudyaev, “Kinetics of the change of density distribution in hot one-sided pressing of a viscous porous body,” Poroshk. Metall., 25, No. 9, 733–737 (1986). https://doi.org/10.1007/BF00797303

J. Happel, Hydrodynamics at Small Reynolds Numbers [in Russian], Mir, Moscow (1976).

C.-C. Zhu, J. Zhu, H. Wu, and H. Lin, “Synthesis of Ti3AlC2 by SHS and thermodynamic calculation based on first principles,” Rare Metals, 34, Is. 2, 107–110 (2015). https://doi.org/10.1007/s12598-013-0174-2

Yu. E. Sheludiak, Thermophysical Properties of Components of Combustible System [in Russian], Publ. House of Technical and Economic Information, Moscow (1992).

L. S. Stelmakh, and A. M. Stolin, “Thermal regimes of compaction during combustion of powder material,” Doklady RAN [in Russian], 373, No. 2, 206–209 (2000).

L. S. Stelmakh, N. N. Zhyliayeva, and A. M. Stolin, “Rheodynamics and heat exchange of hot compaction of powder materials,” Inzhynerno Tekhnicheskii Zhurnal [in Russian], 63, Is. 5, 612–622 (1992).

L. P. Shvedov, “Rheodynamic Model of SBS Processes in the Ti–Al–C System,” in: Abstracts of All-Union Sci. Conf. “Modern Technologies of Material Processing” (Mykolaiv, Nov. 1–2, 2018), Publ. House “Mykolaiv Oblasna Drukarnia”, Mykolaiv (2018), p. 32.

A. D. Rud, A. M. Lakhnik, I. M. Kirian, O. N. Sizonenko, A. D. Zaychenko, N. S. Pristash, and N. D. Rud, “Mechanochemical synthesis and structure of metal-carbon composites based on the MAX phases,” Materials Today: Proc., 5, Is. 12, 26084–26088 (2018). https://doi.org/10.1016/j.matpr.2018.08.034

D. I. Chelpanov, A. N. Yushchishina, and N. I. Kuskova, “Self-propagating high-temperature synthesis in a Ti−Al−C powder system using different carbon precursors,” Surf. Eng. and Appl. Electrochem., 55, Is. 3, 349–356 (2019). https://doi.org/10.3103/S1068375519030049

A. N. Yushchishina, D. I. Chelpanov, and N. I. Kuskova, “Thermodynamic description of chemical reactions in a titanium–aluminum–hexamethylenetetramine system under conditions of self-propagating, high temperature synthesis,” Surf. Eng. and Appl. Electrochem., 56, Is. 4, 469–473 (2020). https://doi.org/10.3103/S1068375520040171

O. M. Syzonenko, A. I. Ivliyev, and Ye. H. Grigoriyev, The Device for Obtaining Consolidated Powder Materials [in Ukrainian], Patent of Ukraine for Invention No. 107729, Publ. on 02.10.2015, Bull. No. 3.

M. X. Zhang, and Y. A. Chang, “Phase diagrams of Ti–Al–C, Ti–Y–O, Nb–Y–O, and Nb–Al–O at 1100°C,” J. of Phase Equilibria, 15, Is. 5, 470–472 (1994). https://doi.org/10.1007/BF02649396

N. A. Svidonovuch, G. P. Okatova, and D. V. Kuis, Materials Science and Construction Materials Technology: Laboratory Practice Using a Metallographic Complex [in Russian], Publ. House of Bielorus. Gos. Tekhn. Univ., Minsk (2007).

A. K. Valeeva, and I. S. Valeev, “On the microhardness and microstructure of copper Cu99,99% at radial-shear rolling,” Lett. Mater., 3, Is. 1, 38–40 (2013). https://doi.org/10.22226/2410-3535-2013-1-38-40

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 59, No. 4, 75–81, July–August, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kuskova, N.I., Syzonenko, O.M., Prystash, M.S. et al. Compacting of Material by Combining Spark Plasma Sintering and Self-Propagating High-Temperature Synthesis in Ti–Al–C System. Mater Sci 59, 459–466 (2023). https://doi.org/10.1007/s11003-024-00798-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11003-024-00798-3