Abstract

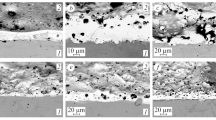

The electric-spark alloying of 45 steel with electrodes made of WC + Co + (2–4)% Cr3C2 hard alloys obtained by sintering on the “coating-substrate” boundary leads to the formation of an intermediate zone. This zone is formed as a result of cavitation mixing of the materials of the electrodes in the course of spark discharge and its composition corresponds to the composition of high-alloy high-speed steel. The intermediate zone increases the cohesion strength between the coating and the substrate, the depth of the obtained layer, and its wear resistance.

Similar content being viewed by others

REFERENCES

I. A. Podchernyaeva, A. D. Panasyuk, V. V. Shchepetov, et al. “Surface modification of AL9 alloy by electric-spark alloying with materials of the AlN-Ti(Zr)B2-Ti(Zr)Si2 system,” Poroshk. Metallurg., No. 3–4, 55 (2004).

I. A. Podchernyaeva, V. A. Lavrenko, A. D. Panasyuk, et al. “Modification of the surface of molybdenum by electric-spark alloying with the help of a composite electrode of Al-Ti(Zr)-N-B system,” Poroshk. Metallurg., No. 7–8, 70 (2003).

A. D. Verkhoturov, Investigation of the Electrode Materials Intended for Electric-Spark Alloying and the Principles of Their Creation [in Russian], Preprint No. 5, Frantsevych Institute for Problems in Materials Science, Ukrainian Academy of Sciences, Kyiv (1980).

A. D. Verkhoturov and I. M. Mukha, Technology of Electric-Spark Alloying of Metal Surfaces [in Russian], Tekhnika, Kyiv (1982).

A. D. Verkhoturov, I. A. Podchernyaeva, L.F. Pryadko, and F. F. Egorov, Electrode Materials for Electric-Spark Alloying [in Russian], Nauka, Moscow (1988).

G. P. Ivanov, Technology of Electric-Spark Hardening of Tools and Machine Parts [in Russian], Mashgiz, Moscow (1961).

G. A. Proshin, Electric-Spark Treatment of Reconditioned Machine Parts [in Russian], Mashgiz, Moscow-Kyiv (1956).

O. V. Paustovs'kyi, S. M. Kyrylenko, and M. P. Berezhnyts'ka, An Electrode Material Based on Tungsten Carbide [in Ukrainian], Declarative Patent for the Invention No. 64429, Bull. No. 2 (2004).

Yu. M. Lakhtin and V. P. Leont'eva, Materials Science [in Russian], Mashinostroenie, Moscow (1980).

Author information

Authors and Affiliations

Additional information

__________

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 41, No. 2, pp. 105–108, March–April, 2005.

Rights and permissions

About this article

Cite this article

Paustovs'kyi, O.V., Kyrylenko, S.N., Alfintseva, R.A. et al. Electric-Spark Alloying of Steels by Materials Based on WK Alloy with Admixtures of Chromium Carbide. Mater Sci 41, 259–264 (2005). https://doi.org/10.1007/s11003-005-0159-x

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11003-005-0159-x