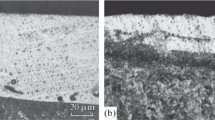

A method is proposed for applying titanium carbide composite coatings by means of combined technology of self-propagating high-temperature synthesis (SHS) and electric-spark alloying (ESA). It is established that use of a Ti + C + Ni powder mixture as SHS reagents, applied to a component surface before ESA, makes it possible to obtain hard ultrafine coatings 0.1 – 0.3 mm thick with a titanium carbide particle size from 0.1 to 5.0 μm.

Similar content being viewed by others

References

A. V. Belyakov , A. N. Gorbachev, and A. O. Fedotov, “Spark against erosion,” Énergonadzor, No. 6(15) (2010).

A. V. Belyakov, V. I. Shapin, and A. N. Gorbachev, “Practice of forming electric-spark coatings for strengthening blade equipment of the flow-through part of thermal and atomic power station steam turbines,” Vestnik IGÉU, No. 4 (2008).

A. G. Merzhanov, “Self-propagating high-temperature synthesis: past, present, and future,” Izv. Vuzov Tsvet. Met., No. 5 (2006).

S. S. Kiparisov, Yu. V. Levinskii, and A. P. Petrov, Titanium Carbide: Preparation, Properties, Application [in Russian], Metallurgiya, Moscow (1987).

A. V. Belyakov, A. N. Gorbachev, and V. I. Shapin, “Development and analysis of device characteristics for forming electric-spark coatings for main and subsidiary thermal and atomic power station equipment,” in: Abstrs. of the 5th Int. Conf. on Materials Science and Condensed Matter Physics and Symposium “Electrical Methods of Materials Treatment” in Memory of Acad. Boris Lazarenko (1910 – 1979 ), Chisinau, Moldova: Elan INC, 2010.

RF Useful Model Pat. 38661, A. V. Belyakov, A. N. Gorbachev, V. I. Shapin, and S. A. Vikhrev, “Device for electric-spark alloying with a drive from a rotating rotor.”

O. P. Reut, B. B. Khina, L. V. Markova, É. N. Tolstyak, and V. V. Sarantsev, “Technology for applying coatings based on titanium carbide by ESA of a component with SHS-reagents,” Lit’e Metall., No. 1 (2007).

O. P. Reut, B. B. Khina, V. V. Sarantsev, and L. V. Markova, “Use of self-propagating high-temperature synthesis and electric-spark treatment for applying composite coatings,” Uprochn. Tekhnol. Pokryt., No. 12 (2007).

A. S. Rogachev, V. M. Shkiro, I. D. Chausskaya, and M. V. Shvetsov, “Gasless combustion in a titanium carbon-nickel system,” Fiz. Gor. Vzryva, No. 6 (1988).

B. B. Khina, “Interaction kinetics in SHS: is the quasi-equilibrium solid-state diffusion model valid?” Int. J. Self-Propagating High-Temp. Synthesis, 14(1) (2005).

M. Kondzumi (ed.), Combustion Synthesis Chemistry [Russian translation], Mir, Moscow (1998).

P. A. Vityaz’, A. F. Il’yushchenko, M. A. Andreev, and L. V. Markova, Solid Lubricant Coatings in Engineering [in Russian], Belorusskaya Nauka, Minsk (2007).

Author information

Authors and Affiliations

Additional information

Translated from Élektricheskie Stantsii, No. 2, February, 2014, pp. 36 – 42.

1 The work was carried out with financial support of the RF Ministry of Education and Science in accordance with state contract No. 14.516.11.0034 “Study of the electric-spark alloying method and improvement of engineering solutions for forming abrasion-, erosion-, and corrosion-resistant coatings on elements of the flow-through part of a new generation of gas turbine installations,” of 03.22.2013.

Rights and permissions

About this article

Cite this article

Belyakov, A.V., Kalugin, R.N., Panteleenko, F.I. et al. Wear Resistance of Coatings Using SHS-Technology Under Electric-Spark Alloying Conditions1 . Power Technol Eng 48, 147–152 (2014). https://doi.org/10.1007/s10749-014-0499-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10749-014-0499-5