Abstract

When subjected to localized blast loading from shallow-buried explosives (e.g., mines buried under sand), how would a sandwich structure dynamically perform has been extensively investigated, both experimentally and numerically, but not analytically. This study aimed therefore to establish an analytical model for preliminary assessment of using sandwich panels with square honeycomb cores for protective applications against shallow-buried explosions, with the influence of boundary conditions (e.g., simply supported versus fully clamped) accounted for. The resulting maximum permanent deflection of the sandwich panel was expressed as an explicit function of explosive mass, sand density, sand moisture content, depth of burial, stand-off distance as well as key sandwich panel geometrical parameters. For validation, the model predictions were compared with existing experimental measurements as well as numerical results obtained with the method of finite elements, with good agreement achieved. The validated analytical model was subsequently employed to quantify the effects of various influencing factors. The maximum deflection was found to increase with increasing explosive mass, sand density, and sand moisture content, but with decreasing stand-off distance. As the height of core was increased, the maximum deflection decreased firstly and then increased, suggesting that selecting a proper core height was critical in the design of sandwich panel constructions for optimal blast resistance. Regardless of boundary conditions, an intersection point existed between the normalize deflection versus normalized impulse curves that correspond separately to the sandwich panel and its monolithic counterpart of equal mass. When the normalized impulse had a magnitude smaller than the intersection value, the sandwich panel exhibited a superior blast resistance to the monolithic one, while the opposite held when the normalized impulse was located to the right of intersection. The normalized impulse corresponding to the intersection was dependent upon face sheet thickness, core height, and core relative density. The proposed analytical model provides valuable guidance for designing high-performance protective structures against intensive impulsive loadings.

Similar content being viewed by others

References

Ansys Inc. Ansys Autodyn User’s Manual. (2018).

Chen, G.C., Zhang, P., Liu, J., Cheng, Y., Wang, H.: Experimental and numerical analyses on the dynamic response of aluminum foam core sandwich panels subjected to localized air blast loading. Mar. Struct. 65, 343–361 (2019)

Clarke, S.D., Fay, S.D., Warren, J.A., Tyas, A., Rigby, S.E., Reay, J.J., Livesey, R., Elgy, I.: Geotechnical causes for variations in output measured from shallow buried charges. Int. J. Impact Eng. 86, 274–283 (2015)

Clarke, S.D., Fay, S.D., Warren, J.A., Tyas, A., Rigby, S.E., Reay, J.J., Livesey, R., Elgy, I.: Predicting the role of geotechnical parameters on the output from shallow buried explosives. Int. J. Impact Eng. 102, 117–128 (2017)

Cleary, P.W.: Prediction of coupled particle and fluid flows using DEM and SPH. Miner. Eng. 73, 85–99 (2015)

De, A.: Numerical simulation of surface explosions over dry, cohesionless soil. Comput. Geotech. 43, 72–79 (2012)

Deshpande, V.S., Mcmeeking, R.M., Wadley, H.N.G., Evans, A.G.: Constitutive model for predicting dynamic interactions between soil ejecta and structural panels. J. Mech. Phys. Solids. 57(8), 1139–1164 (2009)

Dharmasena, K.P., Wadley, H.N.G., Liu, T., Deshpande, V.S.: The dynamic response of edge clamped plates loaded by spherically expanding sand shells. Int. J. Impact Eng. 62, 182–195 (2013)

Dharmasena, K.P., Wadley, H.N.G., Xue, Z.Y., Hutchinson, J.W.: Mechanical response of metallic honeycomb sandwich panel structures to high-intensity dynamic loading. Int. J. Impact Eng. 35(9), 1063–1074 (2008)

Gibson, L.J., Ashby, M.F.: Cellular Solids: Structure and Properties, 2nd edn. Cambridge University Press, New York (1998)

Grujicic, M., Pandurangan, B., Huang, Y., Cheeseman, B.A., Roy, W.N., Skaggs, R.R.: Impulse loading resulting from shallow buried explosives in water-saturated sand. Proc. Inst. Mech. Eng. Part L. 221(1), 21–35 (2007)

Grujicic, M., Pandurangan, B., Mocko, G.M., Hung, S.T., Cheeseman, B.A., Roy, W.N., Skaggs, R.R.: A combined multi-material euler/lagrange computational analysis of blast loading resulting from detonation of buried landmines. Multidiscip. Model Mater. Struct. 4(2), 105–124 (2008)

Holloman, R.L., Deshpande, V., Wadley, H.N.G.: Impulse transfer during sand impact with a cellular structure. Int. J. Impact Eng. 82, 36–58 (2015)

Jones, N.: A theoretical study of the dynamic plastic behavior of beams and plates with finite-deflections. Int. J. Solids Struct. 7(8), 1007–1028 (1971)

Jones, N.: Structural Impact. Cambridge University Press, New York (1989)

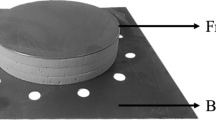

Kyner, A., Dharmasena, K., Williams, K., Deshpande, V., Wadley, H.: Response of square honeycomb core sandwich panels to granular matter impact. Int. J. Impact Eng. 117, 13–31 (2018)

Laine L., Sandvik A.: Derivation of mechanical properties for sand. In: 4th Asia-Pacific conference on shock and impact loads on structures, pp. 361–68. Singapore: CI-Premier. (2001)

Li, Y., Ren, X.B., Zhang, X.Q., Chen, Y.F., Zhao, T., Fang, D.N.: Deformation and failure modes of aluminum foam-cored sandwich plates under air-blast loading. Compos. Struct. 258, 113317 (2021)

Liang, Y.M., Spuskanyuk, A.V., Flores, S.E., Hayhurst, D.R., Evans, A.G.: The response of metallic sandwich panels to water blast. J. Appl. Mech. 74(1), 81–99 (2007)

Mehreganian, N., Fallah, A.S., Louca, L.A.: Plastic dynamic response of simply supported thick square plates subject to localised blast loading. Int. J. Impact Eng. 126, 85–100 (2019)

Pickering, E.G., Yuen, S.C.K., Nurick, G.N., Haw, P.: The response of quadrangular plates to buried charges. Int. J. Impact Eng. 49, 103–114 (2012)

Qiu X., Deshpande V.S., Fleck N.A.: Dynamic response of a clamped circular sandwich plate subject to shock loading. J. App.l Mech. 71(5), 637–45 (2004)

Ramasamy, A., Hill, A.M., Masouros, S.D., Gordon, F., Clasper, J.C., Bull, A.M.: Evaluating the effect of vehicle modification in reducing injuries from landmine blasts. An analysis of 2212 incidents and its application for humanitarian purposes. Proc. Inst. Mech. Eng. Part l. 43(5), 1878–1886 (2011)

Ramasamy, A., Masouros, S.D., Newell, N., Hill, A.M., Proud, W.G., Brown, K.A., Bull, A.M.J., Clasper, J.C.: In-vehicle extremity injuries from improvised explosive devices: current and future foci. Philos. Trans. r. Soc. B Biol. Sci. 366(1562), 160–170 (2011)

Rigby, S.E., Akintaro, O.I., Fuller, B.J., Tyas, A., Curry, R.J., Langdon, G.S., Pope, D.J.: Predicting the response of plates subjected to near-field explosions using an energy equivalent impulse. Int. J. Impact Eng. 128, 24–36 (2019)

Uth, T., Wadley, H.N.G., Deshpande, V.S.: The effect of inclination and stand-off on the dynamic response of beams impacted by slugs of a granular material. Int. J. Solids Struct. 56–57, 154–174 (2015)

Vaziri, A., Hutchinson, J.W.: Metal sandwich plates subject to intense air shocks. Int. J. Solids Struct. 44(6), 2021–2035 (2007)

Wadley, H.N.G., Børvik, T., Olovsson, L., Wetzel, J.J., Dharmasena, K.P., Hopperstad, O.S., Deshpande, V.S., Hutchinson, J.W.: Deformation and fracture of impulsively loaded sandwich panels. J. Mech. Phys. Solids. 61(2), 674–699 (2013)

Wadley, H.N.G., Dharmasena, K.P., Queheillalt, D.T., Chen, Y.C.: Dynamic compression of square honeycomb structures during underwater impulsive loading. J. Mech. Mater. Struct. 2(10), 2025–2048 (2007)

Westine P.S., Morris B.L., Cox P.A., Polch E.Z.: Development of computer program for floor plate response from land mine explosions. Contract Report. 13045 (1985)

Xue, Z.Y., Hutchinson, J.W.: A comparative study of impulse-resistant metal sandwich plates. Int. J. Impact Eng. 30(10), 1283–1305 (2004)

Zhang, D.J., Zhao, Z.Y., Du, S.F., Chen, W., Yang, F., Ni, C., Zhikun, Y., Lu, T.J.: Dynamic response of ultralight all-metallic sandwich panel with 3D tube cellular core to shallow-buried explosives. Sci. China: Technol. Sci. 64(7), 1371–1388 (2021)

Zhu, F., Wang, Z.H., Lu, G.X., Nurick, G.: Some theoretical considerations on the dynamic response of sandwich structures under impulsive loading. Int. J. Impact Eng. 37(6), 625–637 (2010)

Zhu, F., Zhao, L., Lu, G., Wang, Z.: Deformation and failure of blast-loaded metallic sandwich panels—experimental investigations. Int. J. Impact Eng. 35(8), 937–951 (2008)

Zok, F.W., Rathbun, H., He, M., Ferri, E., Mercer, C., McMeeking, R.M., Evans, A.G.: Structural performance of metallic sandwich panels with square honeycomb cores. Philos. Mag. 85(26–27), 3207–3234 (2005)

Zok, F.W., Waltner, S.A., Wei, Z., Rathbun, H.J., McMeeking, R.M., Evans, A.G.: A protocol for characterizing the structural performance of metallic sandwich panels: application to pyramidal truss cores. Int. J. Solids Struct. 41(22–23), 6249–6271 (2004)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Nos.11972185; 12002156); the China Postdoctoral Science Foundation (Grant No.2020M671473); and the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD).

Funding

The authors have no relevant financial or non-financial interests to disclose. All authors certify that they have no affiliations with or involvement in any organization or entity with any financial interest or non-financial interest in the subject matter or materials discussed in this manuscript. The authors have no financial or proprietary interests in any material discussed in this article.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix A

Appendix A

1.1 Validation of assumed equivalence between non-uniform and uniform blast loadings

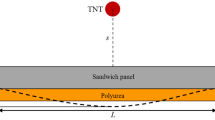

To validate the assumed equivalence between non-uniform and uniform blast loadings, numerical simulations with the method of finite elements were performed. Figure

11 plotted the predicted maximum permanent deflections \(\overline{W} = {W \mathord{\left/ {\vphantom {W {L_{{\text{h}}} }}} \right. \kern-\nulldelimiterspace} {L_{{\text{h}}} }}\) of a sandwich panel subjected to both non-uniform and uniform blast loadings, with the explosive mass me varied from 2 to 6 kg with de/he = 3, at intervals of 1 kg). Table

7 compared the corresponding relative errors. For the comparison, the sandwich panel had a normalized mass of \({{\overline{M}} \mathord{\left/ {\vphantom {{\overline{M}} {\left( {\rho_{{\text{f}}} L_{{\text{h}}} } \right)}}} \right. \kern-\nulldelimiterspace} {\left( {\rho_{{\text{f}}} L_{{\text{h}}} } \right)}} = 0.02\), a normalized core height of \(\overline{h}_{{\text{c}}} = {{h_{{\text{c}}} } \mathord{\left/ {\vphantom {{h_{{\text{c}}} } {L_{{\text{h}}} }}} \right. \kern-\nulldelimiterspace} {L_{{\text{h}}} }} = 0.10\), and a relative density of \(\overline{\rho }_{{\text{c}}} = 0.04\). In addition, the stand-off distance H was 400 mm, the depth of burial δb was 100 mm, the sand density ρs was 2200 kg/m3, and the sand moisture content ws was 0. It was seen from Fig. 3 and Table 7 that the maximum permanent deflections of sandwich panel subjected to non-uniform blast loading were slightly different from those under uniform blast loading, with a maximum relative error less than 6%. Figure

12 compares the deformation evolution of sandwich panel subjected to non-uniform blast loading with that under uniform blast loading, with the explosive mass fixed at me = 3 kg. The core in the middle of sandwich is considerably compressed under non-uniform blast loading as shown in Fig. 12(a), while it is not obviously compressed under uniform blast loading as shown in Fig. 12(b). However, although the deformation mode under non-uniform loading is different from that under uniform loading, the results of Fig. 11 and Table 7 demonstrate that the equivalent method is accurate in predicting the maximum permanent deflection of a sandwich panel. The assumed equivalence between non-uniform and uniform blast loadings in predicting the maximum permanent deflection is therefore validated.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhao, Z., Zhang, D., Chen, W. et al. An analytical model of blast resistance for all-metallic sandwich panels subjected to shallow-buried explosives. Int J Mech Mater Des 18, 873–892 (2022). https://doi.org/10.1007/s10999-022-09605-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10999-022-09605-w