Abstract

The seeds of berry fruits which are considered as a by-product may be valorized by recovering the oil they content. Nevertheless, the conventional extraction methods are time, energy and organic solvents consuming. In order to make extraction more environmental-friendly, alternative methods, like ultrasound-assisted and pulsed electric field-assisted processes, are being developed. The procedure of extraction may however influence the quality of obtained oil. The following study aims to define the effects of ultrasound and pulsed electric field application in the extraction process on the thermal properties, i.e., oxidative stability, melting and cyclic heating/cooling profiles, thermal decomposition characteristics. Additionally, fatty acid profile assessment was included in the study. Seeds of blackberries, blackcurrants, chokeberries, raspberries and redcurrants were used to extract oil. Based on the results, it can be summarized that extraction method influenced the resistance of oils to oxidation. Ultrasound-assisted process resulted in oils with the highest oxidation induction times. Melting profile was slightly influenced by extraction method, with peak temperatures indicating the presence of low-melting and middle-melting triacylglycerol fractions. Differential scanning calorimetry with heat/cool/heat procedure let determine crystallization peak temperatures around − 60 °C, which could be associated with the specific triacylglycerol profile of berry seed oils. The courses of thermogravimetric analysis curves were comparable for all the tested samples. The fatty acid profile study revealed that all the studied thermal properties were affected by the unique fatty acid percentage share, with a great predominance of polyunsaturated fatty acids. Obtained results allowed to conclude that extraction method influenced oxidative stability, thermal properties and fatty acid profile only to some extent. The most promising extraction method among analyzed seems to be ultrasound-assisted extraction as it provided oil with high oxidative stability, typical thermal properties and unchanged fatty acid profile, without being harmful to natural environment due to possible reduction in solvent and time consumption.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Fruit-derived seeds which are considered as a by-product in fruit industry can be reused in order to fulfill circular economy principles. The berry fruit seeds are rich in fat with unique composition and thermal behavior [1,2,3]. The possible methods of obtaining oil include conventional practices, such as cold-pressing or classical solid/liquid extraction. Nevertheless, the conditions of aforementioned processes may influence oil properties and natural environment negatively.

Alternative extraction methods are considered as beneficial for the natural environment due to limited energy consumption and decreased organic solvent usage comparing to conventional extraction methods. The extraction methods classified as alternative are those assisted by ultrasound (US), microwave, pulsed electric field (PEF), enzymes and also supercritical fluid or pressurized liquid extraction techniques. Despite the economic and environmental advantages, the extracts obtained in the alternative processes may present unique properties. Oil obtained throughout non-conventional extraction can be characterized by higher content of bioactive compounds, i.e., sterols, fat soluble vitamins [4,5,6].

To assess the detailed characteristics of oil obtained in different extraction procedures, thermal properties studies appear to be applicable. Thilakarathna et al. [7] described melting and crystallization behavior assessed in differential scanning calorimetry study of mahua seed oil extracted applying US-assisted process, cold-pressing and Soxhlet apparatus. The differences between thermal characteristics of oils were slight however noticeable. Additional studies revealed that eventual changes may occur due to differences in chemical composition of extracted oils, such as waxes presence or triacylglycerol (TAG) structure. Capar et al. [6] studied thermal behavior of cranberry seed oil extracted using different methods (applying US, microwave and Soxhlet apparatus). The differences in obtained results were explained by slightly different saturation level of oils and TAG composition. Based on those studies, it may be concluded that DSC study which recorded the behavior of oil subjected to heating or cooling may be a useful tool to present the extraction effect on the events occurring in oils subjected to temperature changes. Another study—pressure differential scanning calorimetry (PDSC)—is an accelerated oxidative stability test and was also used to evaluate extraction method impact on oil properties. For example, Bryś et al. [8] used PDSC to compare extraction method influence on pomegranate seed oil oxidative stability. It was concluded that extraction method significantly affected oxidation induction time (OIT) of pomegranate seed oil. Thermogravimetric analysis (TG) which demonstrates mass loss in the sample during gradual temperature increase in the controlled atmosphere can be also used to monitor changes in the material depending on extraction method. Santos et al. [9] compared supercritical CO2 and solid–liquid extraction of sapucaia oil considering TG results. The visible differences were obtained in terms of stability of oil in air atmosphere and gradually increasing temperature.

There is limited data available about novel techniques like PEF or ultrasound influence on the thermal properties of oils obtained from berry seeds. The results obtained in the present study could help explain the consequences of alternative extraction method application on the quality of product. With that knowledge it could be possible to apply more sustainable extraction methods on the larger scale and specify the usage of such oils. The main objective of the following study was to assess the influence of the extraction methods, such as ultrasound-assisted, PEF-assisted and solid–liquid processes on the thermal properties and fatty acid profile of blackberry, blackcurrant, chokeberry, raspberry and redcurrant seed oils. Accordingly, differential scanning calorimetry (DSC) study was carried out to visualize melting characteristics and behavior in the heat–cool–heat cycle. Also, PDSC analysis was conducted in order to determine oxidation induction time, and therefore, the resistance of oils to oxidation in controlled conditions. TG analysis was performed to specify stability of oil and mass losses pattern in progressive heating conditions. Additionally, gas chromatography (GC) study was conducted to combine the results with fatty acid profile of berry seed oils.

Experimental

Material

Fresh fruit of berries: blackcurrant (Ribes nigrum var. Ruben) and redcurrant (Ribes rubrum var. Jonkheer van Tets) were purchased from PPH Fructodor Sp. z o. o., Bolimow, Poland. Raspberry (Rubus idaeus var. Polana) and chokeberry (Aronia melanocarpa var. Nero) were kindly given by local farmers from Pulawy, Poland. Blackberry (Rubus fruticosus var. Brzezina) was kindly supplied by Institute of Horticulture-National Research Institute in Skierniewice, Poland and fruit came from Rubus collection conducted as part of the targeted task of the Polish Ministry of Agriculture and Rural Development—ex situ conservation of genetic resources of horticultural plants. The fruits were kept frozen and then defrosted in the room temperature right before the juice pressing. Approximately 10 kg of fruits were used to press juice in the hydraulic press (HPL 14, Bucher Unipektin, Niederweningen, Switzerland), applying maximum 3 Bar pressure. Pomace left after juice pressing was then dried in the laboratory convective dryer at the temperature of 45 °C and with the air flow of 1.5 m s−1. Dried material was subjected to water activity measurement at 25 ± 0.3 °C using Rotronic Hygrolab C1 (Rotronic AG, Bassersdorf, Switzerland) hygrometer. The water activity of all samples was under 0.4. The seeds were separated from the pomace using sieves.

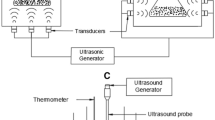

Ultrasound-assisted extraction

Ultrasound-assisted extraction (UAE) process was carried out according to the previously described methodology [10] in the UP400S ultrasound processor (Hielscher Ultrasonics GmbH, Tetlow, Germany) with the output power of 400 W. Seeds (2 g) milled using tube mill (IKA-Werke GmbH & Co. KG, Staufen im Breisgau, Germany) in 20,000 rpm in 30 s time were placed in the falcon tube and filled with extracting medium-n-hexane (99%, Chempur, Piekary Śląskie, Poland) used in solid/liquid ratio at level of 1:15 right before the extraction. To maintain the temperature under 45 °C falcon tube was placed in an ice bath and immersive thermometer was used to control the temperature of the solid-solvent mixture. The two condition options of the extraction were chosen based on the previous studies [11,12,13] and they were: 50% US amplitude in 10 min time and 75% amplitude in 5 min time of treatment (Table 1). After that, extracts were filtered, dried with anhydrous magnesium sulfate and the solvent was evaporated under pressure at minimum level of 70 mbar (vacuum rotary evaporator BR-215, Büchi Labortechnik AG, Flawil, Switzerland). Residual n-hexane was removed from oil samples under nitrogen atmosphere.

Pulsed electric field-assisted extraction

PEF pretreatment was carried out in PEFPilot™ Dual System (Elea Technology GmbH, Quakenbrück, Germany). Whole seeds (2 g) with tap water were treated with PEF applying 8 or 10 kV electrode voltage, 7 µs pulse width, 20 Hz frequency and an adequate number of pulses to achieve energy intake of 50 kV kg−1 (Table 1). Then, filtered and dried in the desiccator seeds were milled in the tube mill and used in extraction conducted in Soxhlet apparatus, with 150 mL of n-hexane during 30 min. Obtained extracts were cooled down, dried with anhydrous magnesium sulfate and subjected to the evaporation and n-hexane removal as described for UAE procedure.

Solid–liquid extraction

Control samples (C) were prepared using solid–liquid extraction. The milled seeds were placed in falcon tubes and mixed with n-hexane in a solid–liquid ratio 1/15 (m/v) and stirred in a water bath for 2 h at temperature of 40 °C. Then samples were filtered, dried and evaporated following the UAE and PEF procedures.

Pressure differential scanning calorimetry

Oxidative stability of oils was determined in PDSC study conducted using a DSC Q20 TA Instrument (TA Instruments, New Castle, DE, USA). Conditions were as follows: oxygen atmosphere with an initial pressure of 1400 kPa and with the 100 mL min−1 oxygen flow rate, temperature − 120 °C. Oxidation induction time was calculated based on the maximum heat flow rate as the point of maximum deviation from the linear baseline on plots interpreted using TA Universal Analysis 2000 software. For each sample, the output was automatically recalculated and presented as the amount of energy per 1 g [14].

Differential scanning calorimetry

DSC studies were carried out with a Q200 DSC equipment (TA Instruments, New Castle, DE, USA) calibrated with high-purity indium. Melting characteristics was determined by the following procedure: samples of 3–4 mg of oil were heated to 80 °C and held for 10 min, in order to melt all the crystals and to erase any thermal memory. After that the samples were cooled to − 80 °C at 10 °C min−1 cooling rate and maintained at − 80 °C for 30 min. Then, the melting profiles were obtained by heating the samples to 80 °C at a heating rate of 15 °C min−1. Additionally, the heat/cool/heat procedure was employed to determine thermal behavior of oils in moderate temperature. Samples (3–4 mg) were heated from ambient temperature to 60 °C, cooled to − 60 °C and heated again to 60 °C. The heating/cooling rate was 10 °C min−1.

Thermogravimetric analysis

The thermogravimetric analysis of oils was performed using Discovery TGA thermogravimetric analyzer (TA Instruments, New Castle, DE, USA) according to the previously published methodology [15] with slight modification. Oil samples (7–8 mg) were placed in the platinum pans. The oxygen atmosphere at a flow rate equal to 10 mL min−1 at atmospheric pressure and in a temperature range of 50–1000 °C with a constant rate of heating set as 10 °C min−1 were used. TG curves illustrating temperature influence on mass loss were used to calculate first derivative (DTG) of a function in the Discovery software (TA Instruments, New Castle, DE, USA). Besides thermal decomposition characteristics, onset temperature (Ton) of oxidation in the heating rate of 10 °C min−1 was determined according to the Li et al. [16] method.

Gas chromatography

The fatty acid profile was assessed in a gas chromatography study. The oil samples were derivatized to methyl esters by mixing with hexane and methanolic potassium hydroxide [17]. Then, using the YL6100 GC apparatus (Young Lin Instrument Co., Ltd., Anyang, Republic of Korea) fitted with a flame ionization detector and a 60-m-long BPX 70 capillary column (SGE Analytical Science, Milton Keynes, UK), the obtained fatty acid methyl esters (FAME) were examined. The nitrogen was used as a carrier gas and split injection mode at a ratio equal to 1:50 was applied. The injector’s temperature was 225 °C, while the detector’s temperature was 250 °C. Temperature program of the oven was as follows: 70 °C for 0.5 min, then heated up to 160 °C with a 15 °C min−1 rate and increased to 200 °C with a heating rate of 1.1 °C min−1 and kept in those conditions for 6 min, after that the sample was heated again to 225 °C with heating rate of 30 °C min−1. The fatty acids were identified based on retention times on the chromatogram compared to the FAME mixture standard (Supelco 37 Component FAME Mix, Sigma-Aldrich, Bellefonte, USA). The results were calculated as a percentage share of every detected fatty acid in the sample [18].

Statistical analysis

Extractions were carried out in three repetitions; all analyses were conducted in triplicate and the results were expressed as a mean ± standard deviation. ANOVA analysis of variance was conducted in the Statistica software (v. 13.3, Statsoft, Kraków, Poland) to determine the effect of extraction method on the results of experiments. Post hoc Tukey’s multiple range test was carried out in order to indicate significant differences between results at a p-value of 0.05. Additionally, hierarchical cluster analysis was carried out and presented in a graphical form.

Results and discussion

Oxidation induction time

The results of pressure differential scanning calorimetry conducted at 120 °C are summarized on the diagram in Fig. 1 (detailed data available in Supplementary material), and the curves obtained in the PDSC study are shown in Fig. 2. It can be observed that OIT of oil depends strictly on the origin of oil. The influence of the extraction method was also noted; however, the tendency and significance differed among the studied oils. In the case of blackberry seed oil, US was more effective extraction method considering OIT of oil than PEF or control. Particularly, US with amplitude 75% applied in 5 min time resulted in blackberry seed oil with the longest OIT. Blackcurrant seed oil extracted in the control conditions was characterized by higher OIT than US or PEF-extracted oils. Chokeberry seed oil extracted by applying US with 75% amplitude during 5 min presented significantly higher OIT comparing to other methods. PEF-assisted extraction resulted in raspberry seed oil with more than 1.5-fold higher OIT than control sample and also higher than US-extracted samples. Considering redcurrant seed oil, 50% amplitude of US applied in 10 min time was the most beneficial in terms of OIT. Taking into account the differences between OIT results for oils extracted in different conditions, the increased OIT may be attributed with accelerated antioxidant compounds extraction subsequently with US or PEF-assisted extraction of oil [19, 20]. The presence of natural antioxidants, like tocopherols, polyphenols, sterols and carotenoids, may prevent oil from oxidation and thus, prolong its stability or shelf life. However, the compounds with antioxidative capacity were described as thermolabile [21] and unstable in the extreme conditions of extensive sonication [22]. Moreover, ultrasound treatment may cause formation of hydroperoxides and degradation of oil [23]. It may be the reason why in some cases, oil extracted using alternative methods was characterized by lower values of OIT. Also, particular conditions of alternative extraction should be determined in the optimization study for each material, as it was noted that, generally, applying US with higher amplitude during shorter time in sonication process and, higher voltage of electrode in PEF-assisted extraction resulted in oil with higher OIT.

Oxidation induction times of berry seed oils obtained in different extraction methods (BB blackberry, BC blackcurrant, CH chokeberry, RB raspberry, RC redcurrant). The results are given as means, results with different letters in the superscript are significantly different (p < 0.05) among samples originating from one type of seeds

Comparing oxidative stability of obtained oils to the other plant-derived oils using PDSC method at 120 °C, all of the studied berry seed oils presented longer OIT than hexane-extracted hempseed oil (13.6–28.9 min) [24], cold-pressed or hexane-extracted strawberry seed oil (9.0–12.8 min) [25, 26]. The OIT of camelina cold-pressed seed oil ranged from 61.4 to 76.2 min [27], of olive oil—from 134.2 to 180.1 min and of rapeseed oil—from 82.4 to 98.5 min [28].

Melting profile of obtained oils

The peak melting temperatures (Tm) coupled with enthalpy changes (ΔHm) values of the transitions observed on the DSC melting curves of oils are shown in Table 2, and the visual presentation of curves is shown in Fig. 3. In the case of all tested samples of blackberry and raspberry seed oils, two events on the curve were observed, first—around − 40 °C and second—around − 20 °C in both cases. The first transition was described by greater enthalpy change; however, higher enthalpy change in the second event was observed in control samples of blackberry and raspberry oils. Chokeberry seed oils were characterized by similar, single events with peak temperature around − 35 °C visible in all tested samples. In the case of blackcurrant seed oil, as well as redcurrant seed oil, single or double transitions were observed, depending on the sample. As regards the PEF-treated samples, one event was noted around − 40 °C, for blackcurrant seed oil, the same course of curve was also recorded for the control sample. The second event, with lower enthalpy change, was observed around − 30 °C for US-extracted blackberry oils and at around − 25 °C for US-extracted and control redcurrant oils. Based on the statistical analysis, it can be observed that considering one source of oil, there were some slight differences among samples extracted in different procedures. However, the differences among samples extracted in the same procedure but applying various conditions of the process were not detected. The melting characteristics of oils is predominantly affected by composition, content and structure of TAG. The detected events on the melting profiles of studied oils correspond mainly with the presence of low-melting TAG (around − 40 °C) and middle-melting TAG (around − 20 °C) [29]. All the TAG present in tested oils were melted completely at temperatures below 0 °C which is typical for TAG with high unsaturation level [30]. That is accordant with the GC study results, which showed high percentage share of polyunsaturated fatty acids in all studied oils. While analyzing DSC melting curves, exothermic peaks before the melting onset might be observed in the case of chokeberry and control samples of raspberry and blackberry seed oils. Their presence was probably connected to the polymorphism phenomenon, particularly solid-to-solid transformation [31].

Although the DSC study may be used as a tool to identify oils or detect their adulteration [32], applying different conditions in the extraction process may influence the content of TAG or their structure [33, 34] and thus, impact the melting behavior recorded in DSC study. However, obtained in the following study DSC curves presented similar courses to the previously published results of berry seed oils with comparable fatty acid profile: raspberry seed oil [35,36,37], blackcurrant, cranberry and strawberry seed oils [26]. In all of the studies, melting curves of oils were characterized by the presence of the main, largest peak with the maximum temperature at around − 40 °C, sometimes accompanied with additional peaks at higher temperature.

Thermal behavior in heat/cool/heat DSC procedure

The specific temperatures of crystallization (Tc) and melting (T′m) events coupled with enthalpy changes (ΔHc, ΔH′m) obtained in the heat/cool/heat procedure are summarized in Supplementary Table 2. The heat/cool/heat procedure was applied to reveal thermal behavior in the cycle of cooling and heating the oil samples, without the initial heating applied in order to erase the crystal memory of oils in the classic DSC melting characteristics assay. Also, different heating/cooling rate was employed. Similarly, as for the aforementioned results of melting curve, the extraction method impact on the heat/cool/heat curve course was recognizable, although slight. Zhang et al. [38] described changes in thermal behavior of papaya seed oil extracted in UAE process comparing to the Soxhlet extraction. Soxhlet extraction yielded in oil with higher Tm and lower Tc than oil obtained in UAE. The temperatures of crystallization recorded in the following procedure were around − 60 °C for all tested oil samples, which is typical for the highly unsaturated TAG presence in the berry seed oils. Also, the enthalpy change is quite low, which is due to low saturation level of berry seed oils. Similar results were previously observed for mango seed oils [39]. Not all the oils presented in the following study were previously assessed for the thermal behavior; however, comparable crystallization temperatures were observed for cold-pressed raspberry seed oils by Rajagukguk et al. [36]. Also, T′m of raspberry seed oil was similar to one of the three detected melting points by Rajagukguk et al. [36]. However, in the aforementioned study, the rate of heating/cooling equal to 1 °C was applied and that might have influenced the results significantly.

The chokeberry seed oil revealed different course of curve, with the exothermic peak around 20 °C regardless of the extraction method. The peak temperature in that area indicates crystallization of highly saturated TAG; however, in that case, it may be contributed to the crystallization of one of polymorphic form phenomenon [31] as the chokeberry seed oil was not characterized by high saturated fatty acids percentage share in the GC study. Indeed, crystallization occurrence in the 20 °C temperature was visible.

Thermogravimetric analysis

The courses of TG/DTG curves were similar for all tested oils and were not influenced by the extraction method. The behavior of oils was typical for the plant-derived fats. The results of TG study showed that oils decomposition in oxygen atmosphere proceeded in three main stages occurring in the temperature range of 180–550 °C (Table 3) with only a trace amount of residue left at 1000 °C. The decomposition progressed with increasing temperature and was associated with the presence of polyunsaturated fatty acids (PUFA), monounsaturated fatty acids (MUFA) and saturated fatty acids (SFA), respectively. The first degradation stage indicated thermal stability of edible oils. All the studied berry seed oils were stable during heating up to around 180 °C, where the decomposition started. In the initial step, decomposition involved liberation of volatile compounds which were formed during TAGs degradation as well as oxygen uptake and peroxides forming which was observed as a small mass increase in the TG curve right before the start of the decomposition. Second decomposition step at temperature range 370–420 °C corresponded with MUFA decomposition and third, in the range of 420–550 °C was associated with SFA degradation [40, 41] (Figs. 4, 5).

Fatty acid profile

The results of fatty acid percentage share of obtained oils is shown in Supplementary Table 3. All of the samples were characterized by high (over 70%) percentage share of polyunsaturated fatty acids, what is a distinctive feature of berry seed derived oils. The most abundant fatty acid was linoleic acid (LA) in case of every tested oil. The proportion of LA varied from 40% in the case of redcurrant seed oil to 70% as regards the chokeberry seed oil. Taking into consideration the extraction influence on the fatty acid profile, there were noted some significant differences in the percentage values; however, noted changes were not sufficient to impact the overall chemical characteristics of oils. The noticeable observation was that the sum of SFA percentage share in the oils extracted using higher temperature (PEF-assisted) was slightly higher comparing to other extraction methods—US-assisted and solid–liquid extraction carried out at 40 °C temperature. That is in agreement with the previous findings for microalgae oil extracted in US-assisted process at different temperatures [42]. Also, Teng et al. [43] proved US-assisted extraction to provide raspberry seed oil with lower SFA than Soxhlet extraction. Wei et al. [44] suggested that higher saturation level in oils extracted using Soxhlet method may be caused by unsaturated lipids oxidation initiated by evaluated temperature and time of extraction. On the other hand, extraction method did not affect fatty acid profile of apple seed oil obtained using US, supercritical fluid or conventional extraction as reported by Gasparini et al. [45]. Applying US-enzyme assisted extraction did not influence the fatty acid composition of lipophilic fraction of raspberry, strawberry and blackberry pomace as well [46]. Taking PEF pretreatment into consideration, previous findings focused mostly on PEF influence on the fatty acid profile of cold-pressed oils. In the case of olive oil [47], rapeseed oil [48] and Niger seed oil [32], content of fatty acids was not affected by PEF pretreatment. In the study in which sunflower seeds underwent PEF pretreatment before hexane solid–liquid extraction, fatty acid profile also remained unaffected comparing to the ultrasound or conventional solid–liquid extraction [49].

Fatty acid profile assessment seems to be useful combined together with the thermal analysis as the fatty acid composition of TAG in oils is inseparably associated with the thermal behavior of oils. The high unsaturation level of TAG corresponds with the low temperature of melting. The characteristic temperature of melting in the case of TAG with only unsaturated fatty acids occurring in their structure is around − 40 °C, so-called moderate unsaturated TAG with unsaturated fatty acids melt at temperature around − 20 °C, saturated TAG melt at temperatures above 0. Similarly, crystallization peaks of highly unsaturated TAG occur in very low temperatures (− 60 °C to − 40 °C) [29]. Also, decomposition monitored in the TGA study depends on the fatty acid profile of fat, as it is closely related to the oxidative stability, assessed in the PDSC study as well [16, 50]. The further analysis of TAG content and structure appears to be necessary to obtain full image of the fatty acid profile influence on the thermal behavior of studied oils.

Statistical approach

Results from PDSC (OIT), DSC (Tm1, ΔHm1, Tc1, ΔHc1), TG (3 mass losses) and GC (sum of SFA, MUFA and PUFA) were used to carry out cluster analysis. The heatmap and dendrogram were the result of statistical analysis and showed similarities among all studied oils. What can be noted is that, generally, among oils obtained from the same source, there were observed only slight differences. Method of extraction usually did not influence studied thermal properties and fatty acid composition. However, differences between oils derived from different seeds were visible. Thus, it can be concluded that thermal properties and fatty acid composition of extracted oils mostly depended on the used material (Figs. 6, 7).

Conclusions

The results of the study allow the following conclusions to be drawn. Extraction method influenced significantly oxidation induction time with ultrasound-assisted extraction to be the most favorable in the case of blackberry, chokeberry (amplitude 75%, 5 min time) and redcurrant (amplitude 50%, 10 min time) seed oils. PEF treatment was the most efficient in the case of raspberry seed oil and no positive impact of alternative extraction methods application was observed in the case of blackcurrant seed oil. Melting and crystallization characteristics courses were not influenced by extraction method; however, some significant differences were observed mostly in the enthalpy change results. Thermogravimetric analysis showed that extraction method may cause minor deviations in the mass losses noted in the same temperature ranges. Also, fatty acid composition was only slightly affected by the extraction method. The studied alternative extraction methods should be considered as accurate substitute for conventional extractions in the case of berry seed oils, as the ultrasound and PEF applications improve oxidative stability still do not deteriorate other thermal properties or fatty acid profile of oils. However, to choose the most efficient conditions detailed optimization should be carried out for each seed oil separately, as the characteristics of oil is mostly affected by its source. Choosing proper conditions may contribute to obtain oil with high resistance to oxidation and may be applied in preparation of oil-based formulas in food industry or cosmetics production. Also, reusing berry fruit seeds considered as a by-product in alternative extraction procedure may bring financial profits as it does not require much energy to maintain yet results in valuable product.

Data availability

Data presented in the following study are available on the reasonable request from the corresponding author.

References

da Silva AC, Jorge N. Bioactive compounds of oils extracted from fruits seeds obtained from agroindustrial waste. Eur J Lipid Sci Technol. 2017. https://doi.org/10.1002/ejlt.201600024.

Piasecka I, Wiktor A, Górska A. Alternative methods of bioactive compounds and oils extraction from berry fruit by-products—a review. Appl Sci. 2022. https://doi.org/10.3390/app12031734.

Zorzi M, Gai F, Medana C, Aigotti R, Morello S, Peiretti PG. Bioactive compounds and antioxidant capacity of small berries. 2020. Foods. https://doi.org/10.3390/foods9050623.

Krumreich FD, Borges CD, Mendonça CRB, Jansen-Alves C, Zambiazi RC. Bioactive compounds and quality parameters of avocado oil obtained by different processes. Food Chem. 2018. https://doi.org/10.1016/j.foodchem.2018.03.048.

Pereira P, Cebola MJ, Oliveira MC, Bernardo-Gil MG. Supercritical fluid extraction vs conventional extraction of myrtle leaves and berries: comparison of antioxidant activity and identification of bioactive compounds. J Supercrit Fluids. 2016. https://doi.org/10.1016/j.supflu.2015.09.006.

Capar T, Dedebas T, Yalcin H, Ekici L. Extraction method affects seed oil yield, composition, and antioxidant properties of European cranberrybush (Viburnum opulus). Ind Crops Prod. 2021. https://doi.org/10.1016/j.indcrop.2021.113632.

Thilakarathna RCN, Siow LF, Tang TK, Chan ES, Lee YY. Physicochemical and antioxidative properties of ultrasound-assisted extraction of mahua (Madhuca longifolia) seed oil in comparison with conventional Soxhlet and mechanical extractions. Ultrason Sonochem. 2023. https://doi.org/10.1016/j.ultrasonch.2022.106280.

Bryś J, Obranović M, Repajić M, Kraljić K, Škevin D, Bryś A, Górska A, Ostrowska-Ligęza E, Wirkowska-Wojdyła M. Comparison of different methods of extraction for pomegranate seeds. Proceedings. 2020. https://doi.org/10.3390/foods_2020-07657.

dos Santos OV, Carvalho RN, da Costa CEF, da Lannes S SC. Chemical, chromatographic-functional, thermogravimetric-differential and spectroscopic parameters of the sapucaia oil obtained by different extraction methods. Ind Crops Prod. 2019. https://doi.org/10.1016/j.indcrop.2019.02.043.

Piasecka I, Brzezińska R, Ostrowska-Ligęza E, Wiktor A, Górska A. Ultrasound-assisted extraction of cranberry seed oil: food waste valorization approach. Eur Food Res Technol. 2023. https://doi.org/10.1007/s00217-023-04326-6.

Hernández-Santos B, Rodríguez-Miranda J, Herman-Lara E, Torruco-Uco JG, Carmona-García R, Juárez-Barrientos JM, et al. Effect of oil extraction assisted by ultrasound on the physicochemical properties and fatty acid profile of pumpkin seed oil (Cucurbita pepo). Ultrason Sonochem. 2016;31:429–36. https://doi.org/10.1016/J.ULTSONCH.2016.01.029.

Rojo-Gutiérrez E, Carrasco-Molinar O, Tirado-Gallegos JM, Levario-Gómez A, Chávez-González ML, Baeza-Jiménez R, Chávez-Zamudio R, Martínez-Sánchez CE. Evaluation of green extraction processes, lipid composition and antioxidant activity of pomegranate seed oil. J Food Meas Charact. 2021. https://doi.org/10.1007/s11694-020-00804-7.

Senrayan J, Venkatachalam S. A short extraction time of vegetable oil from Carica papaya L. seeds using continuous ultrasound acoustic cavitation: analysis of fatty acid profile and thermal behavior. J Food Process Eng. 2019. https://doi.org/10.1111/jfpe.12950.

Wirkowska-Wojdyła M, Bryś J, Górska A, Ostrowska-Ligęza E. Effect of enzymatic interesterification on physiochemical and thermal properties of fat used in cookies. LWT. 2016. https://doi.org/10.1016/j.lwt.2016.07.040.

Dolatowska-Żebrowska K, Ostrowska-Ligęza E, Wirkowska-Wojdyła M, Bryś J, Górska A. Characterization of thermal properties of goat milk fat and goat milk chocolate by using DSC, PDSC and TGA methods. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08181-0.

Li J, Liu J, Sun X, Liu Y. The mathematical prediction model for the oxidative stability of vegetable oils by the main fatty acids composition and thermogravimetric analysis. LWT. 2018. https://doi.org/10.1016/j.lwt.2018.05.003.

Polish Norm: PN-EN ISO: 5509:2001. Oil and vegetable and animal fats. Preparation of methyl ester of fatty acids. Warsaw Poland: Polish Committee for Standardization; 2001.

Bryś J, Flores lns FV, Grska A, Wirkowska-Wojdyła M, Ostrowska-Ligęza E, Bry A. Use of GC and PDSC methods to characterize human milk fat substitutes obtained from lard and milk thistle oil mixtures. J Therm Anal Calorim. 2017. https://doi.org/10.1007/s10973-017-6452-8.

Bimakr M, Rahman RA, Taip FS, Adzahan NM, Islam Sarker MZ, Ganjloo A. Optimization of ultrasound-assisted extraction of crude oil from winter melon (Benincasa hispida) seed using response surface methodology and evaluation of its antioxidant activity, total phenolic content and fatty acid composition. Molecules. 2012. https://doi.org/10.3390/molecules171011748.

Guderjan M, Elez-Martínez P, Knorr D. Application of pulsed electric fields at oil yield and content of functional food ingredients at the production of rapeseed oil. Innov Food Sci Emerg Technol. 2007. https://doi.org/10.1016/j.ifset.2006.07.001.

Kaseke T, Opara UL, Fawole OA. Fatty acid composition, bioactive phytochemicals, antioxidant properties and oxidative stability of edible fruit seed oil: effect of preharvest and processing factors. Heliyon. 2020. https://doi.org/10.1016/j.heliyon.2020.e04962.

Pingret D, Fabiano-Tixier AS, Chemat F. Degradation during application of ultrasound in food processing: a review. Food Control. 2013. https://doi.org/10.1016/j.foodcont.2012.11.039.

Chemat F, Grondin I, Sing ASC, Smadja J. Deterioration of edible oils during food processing by ultrasound. Ultrason Sonochem. 2004. https://doi.org/10.1016/S1350-4177(03)00127-5.

Bryś A, Bryś J, Mellado ÁF, Głowacki S, Tulej W, Ostrowska-Ligęza E, Koczoń P. Characterization of oil from roasted hemp seeds using the PDSC and FTIR techniques. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08640-8.

Raczyk M, Bryś J, Brzezińska R, Ostrowska-Ligęza E, Wirkowska-Wojdyła M, Górska A. Raspberry and blackberry seed oils intended for cosmetic purposes. Acta Sci Pol Technol Aliment. 2021. https://doi.org/10.17306/J.AFS.2021.0884.

Górska A, Piasecka I, Wirkowska-Wojdyła M, Bryś J, Kienc K, Brzezińska R, et al. Berry seeds—a by-product of the fruit industry as a source of oils with beneficial nutritional characteristics. Appl Sci. 2023. https://doi.org/10.3390/app13085114.

Islam M, Muzolf-Panek M, Fornal E, Tomaszewska-Gras J. DSC isothermal and non-isothermal assessment of thermo-oxidative stability of different cultivars of Camelina sativa L. seed oils. J Therm Anal Calorim. 2022. https://doi.org/10.1007/s10973-022-11367-8.

Ciemniewska-Żytkiewicz H, Ratusz K, Bryś J, Reder M, Koczoń P. Determination of the oxidative stability of hazelnut oils by PDSC and Rancimat methods. J Therm Anal Calorim. 2014. https://doi.org/10.1007/s10973-014-3861-9.

Embaby HE, Miyakawa T, Hachimura S, Muramatsu T, Nara M, Tanokura M. Crystallization and melting properties studied by DSC and FTIR spectroscopy of goldenberry (Physalis peruviana) oil. Food Chem. 2022. https://doi.org/10.1016/j.foodchem.2021.130645.

Gutiérrez LF, Ratti C, Belkacemi K. Effects of drying method on the extraction yields and quality of oils from quebec sea buckthorn (Hippophaë rhamnoides L.) seeds and pulp. Food Chem. 2008. https://doi.org/10.1016/j.foodchem.2007.06.058.

Jafari M, Kadivar M, Keramat J. Detection of adulteration in Iranian olive oils using instrumental (GC, NMR, DSC) methods. J Am Oil Chem Soc. 2009. https://doi.org/10.1007/S11746-008-1333-8.

Mohseni NM, Mirzaei H, Moghimi M. Optimized extraction and quality evaluation of Niger seed oil via microwave-pulsed electric field pretreatments. Food Sci Nutr. 2020. https://doi.org/10.1002/FSN3.1396.

Samaram S, Mirhosseini H, Tan CP, Ghazali HM. Ultrasound-assisted extraction (UAE) and solvent extraction of papaya seed oil: yield, fatty acid composition and triacylglycerol profile. Molecules. 2013. https://doi.org/10.3390/molecules181012474.

Rezvankhah A, Emam-Djomeh Z, Safari M, Askari G, Salami M. Microwave-assisted extraction of hempseed oil: studying and comparing of fatty acid composition, antioxidant activity, physiochemical and thermal properties with Soxhlet extraction. J Food Sci Technol. 2019. https://doi.org/10.1007/s13197-019-03890-8.

Oomah BD, Ladet S, Godfrey DV, Liang J, Girard B. Characteristics of raspberry (Rubus idaeus L.) seed oil. Food Chem. 2000. https://doi.org/10.1016/S0308-8146(99)00260-5.

Rajagukguk YV, Islam M, Tomaszewska-Gras J. Influence of seeds’ age and clarification of cold-pressed raspberry (Rubus idaeus L.) oil on the DSC oxidative stability and phase transition profiles. 2023. Foods. https://doi.org/10.3390/foods12020358.

Rajagukguk YV, Islam M, Grygier A, Tomaszewska-Gras J. Thermal and spectroscopic profiles variation of cold-pressed raspberry seed oil studied by DSC, UV/VIS, and FTIR techniques. J Food Compos Anal. 2023. https://doi.org/10.1016/J.JFCA.2023.105723.

Zhang W, Pan YG, Huang W, Chen H, Yang H. Optimized ultrasonic-assisted extraction of papaya seed oil from Hainan/Eksotika variety. Food Sci Nutr. 2019. https://doi.org/10.1002/FSN3.1125.

Lieb VM, Schuster LK, Kronmüller A, Schmarr HG, Carle R, Steingass CB. Fatty acids, triacylglycerols, and thermal behaviour of various mango (Mangifera indica L.) kernel fats. Food Res Int. 2019. https://doi.org/10.1016/j.foodres.2018.08.070.

Gouveia de Souza A, Oliveira Santos JC, Conceição MM, Dantas Silva MC, Prasad S. A thermoanalytic and kinetic study of sunflower oil. Braz J Chem Eng. 2004;21:265–73.

Dodoo D, Adjei F, Tulashie SK, Adukpoh KE, Agbolegbe RK, Gawou K, Manu GK. Quality evaluation of different repeatedly heated vegetable oils for deep-frying of yam fries. Meas Food. 2022. https://doi.org/10.1016/j.meafoo.2022.100035.

Zarrinmehr MJ, Daneshvar E, Nigam S, Gopinath KP, Biswas JK, Kwon EE, Wang H, Farhadian O, Bhatnagar A. The effect of solvents polarity and extraction conditions on the microalgal lipids yield, fatty acids profile, and biodiesel properties. Bioresour Technol. 2022. https://doi.org/10.1016/j.biortech.2021.126303.

Teng H, Chen L, Huang Q, Wang J, Lin Q, Liu M, Lee WY, Song H. Ultrasonic-assisted extraction of raspberry seed oil and evaluation of its physicochemical properties, fatty acid compositions and antioxidant activities. PLoS ONE. 2016. https://doi.org/10.1371/journal.pone.0153457.

Wei C, Xiao K, Li H, Qi Y, Zou Z, Liu Z. Optimization of ultrasound assisted aqueous enzymatic extraction of oil from Cinnamomum camphora seeds. LWT. 2022. https://doi.org/10.1016/j.lwt.2022.113689.

Gasparini A, Ferrentino G, Angeli L, Morozova K, Zatelli D, Scampicchio M. Ultrasound assisted extraction of oils from apple seeds: a comparative study with supercritical fluid and conventional solvent extraction. Innov Food Sci Emerg Technol. 2023. https://doi.org/10.1016/j.ifset.2023.103370.

Davidson M, Louvet F, Meudec E, Landolt C, Grenier K, Périno S, Ouk TS, Saad N. Optimized single-step recovery of lipophilic and hydrophilic compounds from raspberry, strawberry and blackberry pomaces using a simultaneous Ultrasound-Enzyme-Assisted Extraction (UEAE). Antioxidants. 2023. https://doi.org/10.3390/antiox12101793.

Leone A, Tamborrino A, Esposto S, Berardi A, Servili M. Investigation on the effects of a pulsed electric field (PEF) continuous system implemented in an industrial olive oil plant. 2022. Foods. https://doi.org/10.3390/foods11182758.

Mazroei Seydani L, Gharachorloo M, Asadi G. Use of pulsed electric field to extract rapeseed oil and investigation of the qualitative properties of oils. J Food Process Eng. 2022. https://doi.org/10.1111/JFPE.14149.

Moradi N, Rahimi M. Effect of simultaneous ultrasound/pulsed electric field pretreatments on the oil extraction from sunflower seeds. Sep Sci Technol. 2018. https://doi.org/10.1080/01496395.2018.1443131.

Kerrihard AL, Nagy K, Craft BD, Beggio M, Pegg RB. Oxidative stability of commodity fats and oils: modeling based on fatty acid composition. J Am Oil Chem Soc. 2015. https://doi.org/10.1007/S11746-015-2686-4.

Acknowledgements

Authors would like to acknowledge MSc Justyna Wójcik-Seliga from Cultivar Testing, Nursery and Gene Bank Resources Department, Institute of Horticulture-National Research Institute in Skierniewice, Poland for providing Rubus var. Brzezina fruits cultivated from the gene bank collection in Dabrowice, Poland.

Funding

Some research equipment was purchased as part of the “Food and Nutrition Centre—modernisation of the WULS campus to create a Food and Nutrition Research and Development Centre (CŻiŻ)” co-financed by the European Union from the European Regional Development Fund under the Regional Operational Programme of the Mazowieckie Voivodeship for 2014–2020 (Project No. RPMA.01.01.00-14-8276/17).

Author information

Authors and Affiliations

Contributions

Iga Piasecka involved in conceptualization, methodology, data curation, formal analysis, investigation, visualization, software, validation, and writing—original draft. Ewa Ostrowska-Ligęza involved in methodology, formal analysis, and visualization. Artur Wiktor involved in methodology, formal analysis, and supervision. Agata Górska involved in conceptualization, writing—review and editing, supervision, administration of study, and funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

Authors declare no conflicts of interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Piasecka, I., Ostrowska-Ligęza, E., Wiktor, A. et al. Ultrasound and pulsed electric field treatment effect on the thermal properties, oxidative stability and fatty acid profile of oils extracted from berry seeds. J Therm Anal Calorim (2024). https://doi.org/10.1007/s10973-024-13230-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10973-024-13230-4