Abstract

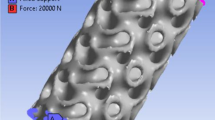

Since the introduction of 3D printing to biomedical fields, numerous advancements have been achieved in tissue engineering due to the advantages it offers. However, 3D-printed polymeric scaffolds may lack certain properties, impacting their functionality and success, such as bioactivity and cell affinity. In this study, the dip coating method was employed to enhance the biological and mechanical properties of 3D-printed polylactic acid (PLA) scaffolds using fused deposition modeling (FDM) technology. Specifically, the scaffolds were dip-coated with a polyvinyl alcohol (PVA)/nano-diopside solution. The thermal features of the 3D-printed scaffolds were analyzed using the differential scanning calorimetry method, revealing a calculated crystallinity of about 13%. To assess bioactivity, both coated and non-coated scaffolds were immersed in simulated body fluid (SBF) for 28 days, and their evaluation was conducted through scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopy (EDAX). At 40 °C, compared to the thermal conductivity of the nanofluid, the thermal conductivities of the non-coated 3D-printed sample and the coated 3D-printed sample were reduced by 9.91 and 22.52%, respectively. The results of this study guided the design and fabrication of improved tissue engineering scaffolds for bone regeneration applications.

Similar content being viewed by others

References

Yan Q, Dong H, Su J, Han J, Song B, Wei Q, Shi Y. A review of 3D printing technology for medical applications. Eng. 2018;4(5):729–42.

Lee JY, An J, Chua CK. Fundamentals and applications of 3D printing for novel materials. Appl Mater Today. 2017;7:120–33.

Bracaglia LG, Smith BT, Watson E, Arumugasaamy N, Mikos AG, Fisher JP. 3D printing for the design and fabrication of polymer-based gradient scaffolds. Acta Biomater. 2017;56:3–13.

Oliveira TT, Reis AC. Fabrication of dental implants by the additive manufacturing method: a systematic review. J Prosthet Dent. 2019;122(3):270–4.

Wang C, Huang W, Zhou Y, He L, He Z, Chen Z, He X, Tian S, Liao J, Lu B, Wei Y. 3D printing of bone tissue engineering scaffolds. Bioact Mater. 2020;5(1):82–91.

Madrid AP, Vrech SM, Sanchez MA, Rodriguez AP. Advances in additive manufacturing for bone tissue engineering scaffolds. Mater Sci Eng C. 2019;100:631–44.

Wang Y, Jie Yu, Qi C, Zhang W, Liang L. Secondary vortex drag reduction and heat transfer enhancement of nanofluids in hierarchical microchannels applied to thermal management of electronic components. Appl Therm Eng. 2024;236: 121588.

Chen T, Wang Y, Qi C, Chen L, Tang Z. Effects of metal foam filling heights and tilt angles on the cooling performance of a heat sink filled with nanofluids. Int Commun Heat Mass Transf. 2022;138: 106326.

Raj KH, Gnanavel S, Ramalingam S. Investigation of 3D printed biodegradable PLA orthopedic screw and surface modified with nanocomposites (Ti–Zr) for biocompatibility. Ceram Int. 2023;49(5):7299–307.

Prasad K, Bazaka O, Chua M, Rochford M, Fedrick L, Spoor J, Symes R, Tieppo M, Collins C, Cao A, Markwell D. Metallic biomaterials: current challenges and opportunities. Mater. 2017;10(8):884.

Zhou X, Feng Y, Zhang J, Shi Y, Wang L. Recent advances in additive manufacturing technology for bone tissue engineering scaffolds. J Adv Manuf Technol. 2020;108:3591–606.

Dehghanghadikolaei A, Fotovvati B. Coating techniques for functional enhancement of metal implants for bone replacement: a review. Mater. 2019;12(11):1795.

Koju N, Sikder P, Ren Y, Zhou H, Bhaduri SB. Biomimetic coating technology for orthopedic implants. Curr Opin Chem Eng. 2017;15:49–55.

Priyadarshini B, Rama M, Chetan, Vijayalakshmi U. Bioactive coating as a surface modification technique for biocompatible metallic implants: a review. J Asian Ceram Soc. 2019;7(4):397–406.

Javadi A, Solouk A, Nazarpak MH, Bagheri F. Surface engineering of titanium-based implants using electrospraying and dip coating methods. Mater Sci Eng C. 2019;99:620–30.

Eawsakul K, Tancharoen S, Nasongkla N. Combination of dip coating of BMP-2 and spray coating of PLGA on dental implants for osseointegration. J Drug Deliv Technol. 2021;61: 102296.

Catauro M, Bollino F, Giovanardi R, Veronesi P. Modification of Ti6Al4V implant surfaces by biocompatible TiO2/PCL hybrid layers prepared via sol-gel dip coating: Structural characterization, mechanical and corrosion behavior. Mater Sci Eng C. 2017;74:501–7.

Kumar A, Han SS. PVA-based hydrogels for tissue engineering: a review. Int J Polym Mater. 2017;66(4):159–82.

Vashisth P, Pruthi V. Synthesis and characterization of crosslinked gellan/PVA nanofibers for tissue engineering application. Mater Sci Eng C. 2016;67:304–12.

Verma C, Quraishi MA. Polyvinyl alcohol (PVA) as a biodegradable polymeric anticorrosive material: a review on present advancements and future directions. Corros Eng Sci. 2022;57(8):796–812.

Zhao C, Liu W, Zhu M, Wu C, Zhu Y. Bioceramic-based scaffolds with antibacterial function for bone tissue engineering: a review. Bioact Mater. 2022;18:383–98.

Shekhawat D, Singh A, Banerjee MK, Singh T, Patnaik A. Bioceramic composites for orthopaedic applications: a comprehensive review of mechanical, biological, and microstructural properties. Ceram Int. 2021;47(3):3013–30.

Shuai C, Yu L, Feng P, Gao C, Peng S. Interfacial reinforcement in bioceramic/biopolymer composite bone scaffold: the role of coupling agent. Colloids Surf B Biointerfaces. 2020;193: 111083.

Abbas Z, Dapporto M, Tampieri A, Sprio S. Toughening of bioceramic composites for bone regeneration. J Compos Sci. 2021;5(10):259.

Sobhani A, Salimi E. Low temperature preparation of diopside nanoparticles: in-vitro bioactivity and drug loading evaluation. Sci Rep. 2023;13(1):16330.

Wu Z, Kong B, Liu R, Sun W, Mi S. Engineering of corneal tissue through an aligned PVA/collagen composite nanofibrous electrospun scaffold. Nanomater. 2018;8(2):124.

Cao XY, Tian N, Dong X, Cheng CK. Implant coating manufactured by micro-arc oxidation and dip coating in resorbable polylactide for antimicrobial applications in orthopedics. Coatings. 2019;9(5):284.

Maróti P, Varga P, Ferencz A, Ujfalusi Z, Nyitrai M, Lőrinczy D. Testing of innovative materials for medical additive manufacturing by DTA. J Therm Anal Calorim. 2019;136:2041–8.

Kiran AS, Kizhakeyil A, Ramalingam R, Verma NK, Lakshminarayanan R, Kumar TS, Doble M, Ramakrishna S. Drug loaded electrospun polymer/ceramic composite nanofibrous coatings on titanium for implant related infections. Ceram Int. 2019;45(15):18710–20.

Hassanajili S, Karami-Pour A, Oryan A, Talaei-Khozani T. Preparation and characterization of PLA/PCL/HA composite scaffolds using indirect 3D printing for bone tissue engineering. Mater Sci Eng C. 2019;104: 109960.

Li X, Yuan Y, Liu L, Leung YS, Chen Y, Guo Y, Chai Y, Chen Y. 3D printing of hydroxyapatite/tricalcium phosphate scaffold with hierarchical porous structure for bone regeneration. BDM. 2020;3:15–29.

Aki D, Ulag S, Unal S, Sengor M, Ekren N, Lin CC, Yılmazer H, Ustundag CB, Kalaskar DM, Gunduz O. 3D printing of PVA/hexagonal boron nitride/bacterial cellulose composite scaffolds for bone tissue engineering. Mater Des. 2020;196: 109094.

Rafiee N, Karbasi S, Nourbakhsh AA, Amini K. Natural hydroxyapatite/diopside nanocomposite scaffold for bone tissue engineering applications: physical, mechanical, bioactivity and biodegradation evaluation. Mater Technol. 2022;37(1):36–48.

Lee H, Shin DY, Na Y, Han G, Kim J, Kim N, Bang SJ, Kang HS, Oh S, Yoon CB, Park J. Antibacterial PLA/Mg composite with enhanced mechanical and biological performance for biodegradable orthopedic implants. Biomater Adv. 2023;152: 213523.

Zhang X, Malekahmadi O, Sajadi SM, Li Z, Abu-Hamdeh NH, Rawa MJ, Al-Ebrahim MA, Karimipour A, Viet HP. Thermomechanical properties of coated PLA-3D-printed orthopedic plate with PCL/Akermanite nano-fibers: experimental procedure and AI optimization. JMR&T. 2023;27:1307–16.

Fico D, Esposito Corcione C, Acocella MR, Rizzo D, De Carolis V, Maffezzoli A. Thermal stabilization of recycled PLA for 3D printing by addition of charcoal. J Therm Anal Calorim. 2023;148(23):13107–19.

Abdellahi M, Najafinezhad A, Ghayour H, Saber-Samandari S, Khandan A. Preparing diopside nanoparticle scaffolds via space holder method: simulation of the compressive strength and porosity. JMBBM. 2017;72:171–81.

Fundamentals Handbook, (American Society of Heating, Refrigerating and Air-Conditioning Engineer (ASHRAE), 2009) https://www.ashrae.org/technical-resources/ashrae-handbook/ashrae-handbook-online

Fischer EW, Sterzel HJ, Wegner GK. Investigation of the structure of solution grown crystals of lactide copolymers by means of chemical reactions. Kolloid-Zeitschrift und Zeitschrift für Polymere. 1973;251:980–90.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yuanlei, S., Andriukaitis, D., Pham, V. et al. Study of the bio-nanofluid heat transfer rate and thermo-physical properties of fused deposition modeling of bone scaffold dip-coated by polyvinyl alcohol/nano-diopside. J Therm Anal Calorim (2024). https://doi.org/10.1007/s10973-024-13213-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10973-024-13213-5