Abstract

In the present investigation, thermodynamic/eco/environmental analysis of the relationship between time-dependent particle deposition and thermal-based losses and incident solar radiation intensity on the PV front cover glass during the months with the least precipitation in the city of Samsun (Turkey) was performed. To evaluate the effect of dust accumulation, controlled experiments were carried out where the surface of one set of PV panels was periodically cleaned with water and the other one was left to natural contamination. The results showed that over three months, the difference in energy loss rates between cleaned and uncleaned PV arrays ranged from 2.53% to 8.1%, with the exergy efficiency difference measured at 1.3%–2.44%. According to the energy-based analyzes, August was the most effective month, with cleaned PV arrays reducing CO2 emissions by 401.5 kg and saving $6.02, compared to uncleaned PV arrays which reduced emissions by 362.21 kg and cost $5.43, respectively. Similarly, in the exergy-based evaluation, August was the most efficient month, with cleaned PV arrays decreasing CO2 emissions by 401.5 kg and saving $6.02, compared to uncleaned PV arrays, which dropped CO2 emissions by 362.21 kg and costing $5.43, respectively. While the cleaned surfaces were initially positive, a decrease was observed over time. However, the efficiency of PV decreased with increasing panel temperature. The study concludes that PV surfaces need to be cleaned at certain intervals, depending on the location’s weather conditions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Sustainable development is crucial in addressing the issues caused by climate change resulting from waste generated by production and consumption, driven by the ever-increasing global population's needs. Photovoltaics (PV) is a pioneering renewable energy source that has been extensively used to harness unlimited and free solar energy. With its proven track record, PV is a reliable solution to meet the energy needs of the future while reducing our carbon footprint. The COVID-19 outbreak has caused fluctuations in oil prices, which has sparked a growing interest in incorporating renewable energy sources into power systems. PV power systems are becoming increasingly popular in various countries due to their low maintenance and operational costs, as well as their lack of greenhouse gas (GHG) emissions [1]. The efficiency of PV modules can be affected by various external and internal factors, including weather conditions, construction, installation, maintenance, and preservation. As a result, it is crucial to consider these factors when evaluating the performance of PV modules. It is important to note that several environmental parameters can impact the efficiency of PV technologies [2]. It is important to note that with the appropriate expertise and attention to detail, these factors can be effectively managed to optimize the performance of PV modules. Although environmental considerations remain challenging, the structural aspects of PV technology and installation procedures have significantly improved. It is crucial to note that various factors, including solar irradiation, operating temperature, reflection, shading, air pollution, and dust accumulation, can have a detrimental effect on the performance of photovoltaic systems [3]. The impact of wind-driven dust accumulation on photovoltaic arrays is a well-established fact that affects panels in many locations worldwide. Furthermore, pollution buildup on PV modules can significantly impact the operation of the PV system. It is important to address these factors to ensure optimal performance and efficiency of the photovoltaic system. It is a well-established fact that the performance of PV systems is significantly impacted by climate and air pollutants, as demonstrated by numerous studies conducted worldwide [4,5,6,7,8,9,10,11,12,13,14].

In Sharjah, United Arab Emirates, Hachicha et al. [4] studied the performance of PV power plants subjected to dust deposition in both indoor and outdoor conditions. The findings revealed that energy loss rose by 12.7% and particle density increased by about 5.44 g m−2 after five months of testing. In the test results, efficiency decreased with increasing inclination angle, depending on the orientation of the PV surface and the inclination angle, from 37.63% to 10.95%. Darwish et al. [5] discovered that carbon dust had the greatest negative impact on PV performance, reducing it by roughly 99.76% (0–20.27 g m−2) under fixed load and 99.9% (0–41 g m−2) under variable load. Natural dust caused lower reductions, around 98.92% (0–164.38 g m−2) under fixed load and 80% (0–123.28 g m−2) under variable load. In their study, Sadat et al. [6], utilized a scanning electron microscope, X-ray fluorescence, and elemental mapping to comprehensively analyze the properties of dust and its impact on the electrical performance of PV panels. Their findings indicate that an increase in dust density leads to a significant decline in electricity generation effectiveness: conversion efficiency, maximum photovoltaic power, open-circuit current, and short-circuit current all decrease by more than 99% as dust density increases, resulting in shading conditions that are virtually all black. Between January and July 2022, Juaidi et al. [7] investigated the impact of manually and automatically cleaned PV power system panels on electricity production. In this investigation, observations were taken by allowing one panel to remain contaminated for the maximum time—seven months—while the other was being cleaned. The test resulted in a 9.99% decline in power production and a monthly average power loss of 2.93%. The study tried to illustrate how, as a result of global warming, electricity, freshwater, and agriculture are important concerns in Palestine. Abdallah et al. [8] examined the influence of dust deposition on the performance of solar power–producing facilities outside Palestine’s climatic zone. Controlled experiments were carried out in this study, with one PV string being cleaned periodically for 12 months and the other left in the natural environment. According to the experimental results, the productivity difference varied between 8.98% and 13.1%. Analysis of current scientific research shows that the impact of dust and dirt deposition on PV surfaces produced by external variables on PV power generating systems can be assessed using the energy analysis technique. El-Wahhab et al. [9] conducted a comprehensive study on the impact of dirt deposition on PV performance in Cairo, Egypt. They analyzed various parameters including front and backside temperatures, current, voltage, power, and efficiency. Results revealed that increasing dust density correlated with decreased frontside temperatures (6–8 ℃) and increased backside temperatures (2–6 ℃), widening the temperature differential to 5–14 ℃ from the clean module's 3 ℃. Dusty modules exhibited 6–45% lower output power and 13–38% reduced efficiency. Regular cleaning is essential to maintain optimal performance and mitigate degradation caused by dust accumulation. Shaik et al. [10] found that bird droppings caused a significant efficiency loss in PV panels, ranging from 46.42% to 89.18%, while coal dust had a much smaller impact, causing less than 13% efficiency loss. The study confidently concludes that the tilt angles of 0° and 12.91° have a negligible influence on the total output of the PV modules. Zhao et al.'s 2023 [11] experimental study tested the power generation performance of a PV panel in various conditions. The study found that sand accumulation at the front side of the panel resulted in a significant reduction of the maximum power output by 32.2%. The study also identified a certain angle at which the wind speed of 15 m s−1 caused the most significant drop in component performance. At a slope inclination of 60 degrees, the output voltage fraction reaches its minimum of 86.5%, resulting in an energy drop of approximately 13.7%. Kamal et al. [12] conducted a comprehensive investigation into the impact of dust accumulation on the performance of a PV panel, using both theoretical analysis and experimental validation. The authors employed both theoretical analysis and experimental validation to derive the computed I-V and P–V curves of the dirty panel, which were in close agreement with the experimental values. The dusty module exhibited a reduction of 31% in maximum output power, which was attributed to a decrease of 68% in incident radiation due to the build-up of dirt. According to Fodah et al. [13], bird guano accumulation has a significant impact on the thermal characteristics of photovoltaic (PV) panels. The deposition of bird-derived guano induces localized hot spots on the surface of the PV modules, which can increase their operating overtemperature by up to 5%. This, in turn, can cause a decrease in the voltage yield and effectiveness of the PV panels by 26% and 43%, respectively, depending on the guano accumulation. It is important to consider the potential impact of bird guano accumulation on the performance of PV panels. These findings underscore the necessity for meticulous maintenance and servicing of PV modules, potentially through effective cooling and cleaning protocols. Alkharusi et al. [14] conducted a 12-month experimental study on soiling, capturing monthly, seasonal, and annual variations. Coupons mimicking PV module surfaces were exposed outdoors. The study confidently reports a significant decrease of 60–66% in electric power generation.

The popularity of thermodynamic, environmental, and economic methods for analyzing energy production systems is increasing. These methods offer a powerful alternative to studying power generation systems. The quantitative research approach to solar power conversion is based on the first law of thermodynamics, which focuses on energy balance. The article confidently investigates the qualitative method, which covers energy, entropy, and exergy balance, using the first and second laws of thermodynamics [15]. Furthermore, exergy analysis is a powerful tool to assess and compare a power system's performance by focusing on a distinct quantification theory and considering the system's usable energy. Previous studies have demonstrated that production costs in PV power systems can be better evaluated based on exergy analysis [15]. Thermodynamic, environmental, and economic calculations are essential tools for evaluating energy systems and designing optimum PV power systems. Coupled methodologies such as EnergoEnviro, ExergoEnviro, Energoenviroeconomic, and Exergoenviroeconomic analyzes are commonly used. The following presents some of the latest research findings in these areas. Izgi and Akkaya [16] employed exergoeconomic analysis to assess a 750 W PV power system in Istanbul. Seasonal variations impact exergoeconomic parameters. April and August represent spring and summer, respectively. Exergy analysis preceded economic evaluation using the EXCEM method. Energy efficiency ranged from 4.5% to 7.3% in August and 5.5% to 8.5% in April. Exergy efficiency varied between 3% and 5.3% in August and 3.8% and 6.5% in April. Average unit costs of exergy values were 0.214 W $−1 (August) and 0.129 W $−1 (April); energy values were 0.222 W $−1 (August) and 0.134 W $−1 (April). Bayat and Özalp [17] performed energy, exergy, and exergoeconomic analyzes on polycrystalline PV modules in the real climatic conditions of Karabük. They discovered that exergy efficiency was less than three times that of energy and ranged between 9.3% and 18.1%, and Ren values ranged from 0.06 W $−1 to 0.45 W $−1 over the month, with total Rex ranging from 0.05 to 0.43 W $−1. Sreenath et al. [18] conducted a comprehensive study of a 5 MW land-based PV facility across five sites in Malaysia. The study analyzed energy, exergy, economic, and environmental aspects using RETScreen software and a Microsoft Excel-based model. The exergy efficiency ranged from 11.35% (Site 2) to 12.65% (Site 4). The photovoltaic system at Site 2 achieved a greenhouse gas mitigation of 4291 tCO2/annum, with an enviroeconomic parameter of 42,916 USD, energoeconomic efficiency of 0.0147 kWh USD−1, and exergoeconomic parameter of 1.096 kW USD−1. In their 2022 study, Yaghoubirad et al. [19] performed a multi-criteria approach to determine the effect of climatic factors on the efficiency of PV modules. The results showed that Phoenix had the greatest power and exergy efficiencies of 16.59% and 14.36%, respectively. Furthermore, Phoenix was identified as the most cost-effective location, with an electricity price of 0.2312 $/kWh. Portland's environmental and environmental-economic assessments were conducted with great efficiency, resulting in values of 11.2868 kgCO2 and 0.1693$ per year. These results demonstrate the city's commitment to sustainability and responsible resource management. Manjunath et al. [20] conducted an energy and exergy analysis of a 50 W PV module, obtaining experimental data during a typical day to determine optimum temperature and exergy losses during conversion. Results indicated a low exergy efficiency of 21.3%, suggesting limited utilization of solar radiation's high exergy content by silicon modules. The maximum energy and exergy efficiencies were found to be 25.2% and 32.4%, respectively. In their study, Ozturk et al. [21] conducted a comprehensive investigation of a 226.4 MWe grid-tied PV power station in Karapınar, Turkey. The study revealed that the plant had an electrical yield of 75.50%, a maximum electrical yield of 36.42%, a power conversion yield of 22.34%, and an exergy yield of 21.98%. The plant's sustainability index is 1.29. The thermoeconomic and exergoeconomic parameters were calculated using the EXCEM method and are 2.43 W $−1 and 2.32 W $−1, respectively. The study conducted in Koszalin, Poland in 2019 by Kuczynski and Chliszcz [22] compared the energy and exergy efficiency of single-crystal and multi-crystalline solar cells. The results indicate that monocrystalline cells have higher average annual energy efficiency (7.1–8.3%) and annual exergy efficiency (4.9–6.8%) compared to amorphous cells (2.1–2.2% and 0.7–1.3%, respectively).

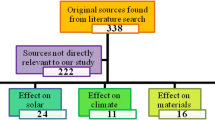

Academic studies have extensively investigated the influence of pollutants on the efficiency of photovoltaic (PV) systems. Promising results, as documented in various scientific papers, reveal improvements in thermal performance achieved through active and passive cooling mechanisms [1, 2, 23,24,25,26]. Table 7 summarizes recent scientific efforts focused on energy analysis, but unfortunately overlooks exergy analysis regarding the effect of dirt accumulation on PV performance on front surfaces. It is important to recognize that exergy analysis, based on the second law of thermodynamics, provides a more holistic assessment that is critical to identifying and mitigating efficiency degradation.

In evaluating a PV power plant, a comprehensive analysis that includes energy (1E), exergy (2E), economic (3E), and environmental (4E) aspects is imperative. This study meticulously examines the impact of natural debris accumulation by comparing the performance parameters of cleaned and uncleaned PV arrays at a grid-connected power plant in Samsun province. By comparing the performance metrics of these arrays, the study firmly establishes a link between capital expenditures and energy/exergy losses.

Given the climatic dynamics of Samsun, Turkey, it's important to recognize that ambient dust deposition on PV panels can have also significant financial and environmental implications. This study decisively illustrates the significant impact of natural dust accumulation on PV panels, integrating comprehensive energy and exergy assessments.

Data collection was conducted from June to August at OMU-Teknopark's 114 kW grid-connected PV power plant under consistent conditions. One PV array was left uncleaned and exposed to natural contaminants, while the other underwent regular cleaning. A comparative analysis of the cleaned and uncleaned PV arrays was conducted. This study confidently juxtaposes the energy and exergy analysis of naturally occurring dust/dirt accumulation on cleaned and uncleaned PV arrays at an on-grid PV power station in Samsun Province, underscoring the need to evaluate PV system performance holistically, considering both economic and environmental factors. A comprehensive analysis of the experimental data was performed using Excel and Origin software.

Experimental setup

This analysis comprehensively evaluates the energy, exergy, environmental, and economic impacts of the systems under consideration. The interplay between initial investment costs and energy/exergy dissipation will be thoroughly assessed. This study quantifies carbon dioxide emissions from these systems and compares the energy, exergy, and economic implications of natural dust/dirt accumulation on both cleaned and uncleaned photovoltaic arrays within a grid-connected photovoltaic energy facility located in Samsun Province. The results demonstrate the significant impact of dust accumulation on the performance of photovoltaic arrays, highlighting the need for regular cleaning to maintain optimal efficiency. Additionally, the economic analysis shows that the cost of cleaning is outweighed by the benefits of increased energy production and reduced emissions.

The experimental data was analyzed using Excel and Origin software. Energy and exergy parameters were computed first, followed by economic and environmental assessments based on the collected data. The on-grid photovoltaic power-producing system covers 10,000 square meters of land with a total capacity of 114 kW. It is located at coordinates 41° 17′ 15.00" N and 36° 20′ 0.60" E, at an elevation of 225 m above sea level. The photovoltaic system consists of 440 polycrystalline PV modules, each with a maximum output power of 260 W. The system operates via four inverters with a maximum capacity of 34.32 kW. The PV arrays are installed on south-facing metal frames inclined at 23° to optimize sunlight exposure throughout the seasons while minimizing construction costs. Table 1 displays the PV panels' characteristics. The construction of this PV facility received support from a European Union-funded initiative. Figure 1 shows a satellite image of the photovoltaic facility.

To compare the performance of cleaned and non-cleaned PV panels, we objectively analyzed data on various parameters, including global solar radiation (IS), maximum generated power (Pm), maximum voltage (Vm), maximum current (Im), PV module temperature (Tmod-cl and Tmod-dirt), ambient temperature (Ta), and wind speed (vw) on selected days. The analysis was conducted with confidence, taking into account all relevant factors and acknowledging multiple perspectives. The investigation analyzed two photovoltaic (PV) arrays, each containing 124 PV panels. Inverter 3 controlled one array that received monthly cleaning, while inverter 4 managed the other array that was left to accumulate natural pollution. Figure 2 illustrates the natural dust accumulation on specific solar panels and the PV surface cleaning process. To compare the values obtained from the two inverters, one string of 124 panels was periodically cleaned. As demonstrated in Fig. 2a, the dirt on the surface of the PV module was meticulously removed using a soft, non-abrasive microfiber material, chlorine-free water, delicate brushes, and a soft sponge.

Experimental data, encompassing both cleaned and dirty PV array series, were gathered twice weekly across diverse days under sunny and clear weather conditions. Measurements occurred during peak sun irradiation between 12:30 and 13:30, with reported data representing the average dataset during this interval. The controlled experimental period spanned three months, from June to August. Total solar irradiance on the front face of the PV modules was determined using a Kipp & Zonen Pyranometer, employing Liu & Jordan’s technique for hourly radiation calculation. The wind velocity (vw) at the solar power facility was quantified utilizing a Wellhise HT-380 digital anemometer, with mean values documented (approximately 2.9 m s−1, 3.2 m s−1, and 3.3 m s−1 for June, July, and August, respectively).

Figure 3 illustrates the time-dependent environmental temperature fluctuations and solar irradiance at the PV system installation location during experimental observations. The average temperature in Samsun Province ranges from 23–25 °C in June 24–28 °C in July, and 25–30 °C in August. Peak irradiance levels in June ranged from 937 W m−2 to 965 W m−2, in July from 948 W m−2 to 958 W m−2, and in August from 853–891 W m−2.

Table 1 lists features of the PV panel's mechanical and electrical systems utilized of the grid-connected PV power generating system. Poly-crystalline panels are popular because they are more affordable and efficient than other panel kinds.

The functional specifications of the 27.6 kW maximum output ABB String Inverter Trio-27.6-TL OUTD (3 phase transformerless) PV employed in the PV power plant are provided in Table 2.

Theoretical analysis of the system

Brief explanations of the effectiveness of cleaned and uncleaned PV arrays, as well as energy, exergy, economic, and environmental analysis computations, will be presented here. In other words, fundamental explanations and mathematical formulae will be provided.

At times of maximum solar radiation, the energy output values of the inverters were recorded. The energy analysis of the PV arrays was done using a mathematical model and Excel software, comparing the cleaned and uncleaned values from these recordings. This section provides a quick explanation of the equations used in energy analysis. The energy contained in the sun’s beams is represented in terms of power:

where IS represents the sunlight intensity, and A represents the lighted panel surface. The PV mechanism converts the direct sunlight that strikes the top of the PV panels into usable power. Then, the peak electrical output of the PV system is stated as:

where Vm and Im represent the maximum voltage and current.

The formula below confidently expresses the energy transformation yield of a typical PV power generation facility [15]:

We can see that efficiency is directly proportional to the maximum current (Im) and voltage (Vm) produced, and inversely proportional to the surface area (A) and radiation intensity (IS) of the module.

Exergy analysis

For more accurate evaluations, the actual efficiency of PV modules should be examined beginning with installation and continuing throughout their service life. Exergy analysis of a PV power generating system involves understanding the exergy for every part that makes up that system, considering the system's losses, which show the energy's quality. Exergy is thus an assessment of the most productive work that a system can complete under constant pressure and temperature conditions through interactions with the environment [15]. Therefore, these concepts will not be discussed here. Sun irradiation's exergy, the exergy input (Exin) to the PV system, is essentially calculated based on three key factors. Because electrical and thermal conversions account for a substantial portion of solar energy conversion, this section will focus on them [17]. The formulae for the PV system's key exergy variables are explained here.

The efficiency of a power generation system is commonly evaluated by the ratio of power output to input. In the case of a photovoltaic (PV) system, the exergy efficiency can be expressed as the ratio of the total exergy output to the total exergy input, as shown below:

Petela (2003) defines the quantity of input exergy given for the functioning of a PV panel as the exergy provided by the solar irradiation impacting the PV panel surface [27]:

where A represents the PV module’s surface area, and Ta and Ts represent the ambient and solar temperatures, respectively.

In the computations, a value of 5777 K for the predicted sun surface temperature was chosen and defined by the PV module’s exergy output [27]:

According to Eq. 6, the PV system's output exergy comprises thermal energy (Exth) and electrical exergy (Exel).

The electrical exergy of a PV module is represented as follows in Eq. 6 (Note that electrical exergy and electrical energy are equivalent.)

The thermal exergy is presented below. It is considered to be the heat dissipation spreading from the PV surface to the surroundings:

where:

where Tmod is the temperature of the cell, hca is the heat transfer coefficient, v is the wind velocity, and TNOCT is the nominal operating cell (module) temperature, which is usually around 45 °C.

By using Eqs. (7) and (8), the output exergy of a solar PV system can be defined as below:

If Eqs. (5) and (12) are replaced in Eq. (4), the exergy efficiency (ratio) is calculated as:

Economic and environmental assessment

The life-cycle parameters of the PV device are assessed for economic and environmental studies of the grid-tied PV power system installed at the OMU-Techno-Park. This analysis considered the original investment, operation and maintenance costs, and other costs of the PV system.

Economic assessment: energy economic, exergy economic, and environmental economic assessment

This cost study takes into account factors such as identifying each PV system component, labor costs, average labor, and material billing. Based on the installation of the PV power system, average expenses are estimated for system operation, permits, grid connection, sales and taxes, installer operational overheads, and profit margin. As is commonly known, the price for each kWh of electricity generated by any of these PV panels is the most essential aim of economic analysis of PV power production systems. Since the PV arrays are connected to the electrical grid, the generated electricity is sold directly to the power company.

The energy and economic aspects of an electricity generating system are examined together in an energy economic study. Similarly, when exergy and economic analysis are combined, it is referred to as 'exergy economic analysis.' Fortunately, more detailed insight into the production costs of any power generation system can be obtained with the energy and exergy economic analysis. In addition, the environmental economic assessment has an impact on the financial value of the quantified GHG reduction and the profitability of the PV project.

This can be achieved by reducing exergy loss and maximizing the net present value (NPV). By minimizing exergy loss, we can ensure the viability of the PV system. The exergy economic variable represents the fraction of exergy lost or gained to the annual cost. To optimize a PV power system, it is crucial to minimize the exergy economic parameter. Identifying the losses of the energy system components is an important step toward minimizing exergy loss. When calculating exergy gain, we must aim to maximize output. Additionally, environmental economic analysis should focus on mitigating the pollution caused by a system to its environment and promoting the use of renewable energy technology for the future. By implementing these strategies, we can ensure a sustainable future for our environment and economy.

Environmental analysis

Identifying, reporting, and examining harmful emissions from energy production systems is vital. These are indirect pollutants caused by using fossil fuels in energy generation systems, which are necessary for people throughout their life cycle. As a result, a multi-criteria study of the ecological impact of cleaned and uncleaned photovoltaic arrays was undertaken, including 'Energy-Environmental' and 'Exergy-Environmental' assessments.

The energy-environmental analysis takes into account the energy generated during a module's operation and the amount of carbon dioxide released from cleaned and uncleaned photovoltaic (PV) arrays. A carbon footprint analysis is a component of a full life cycle evaluation of a product, service, or method. As a result, the carbon footprint is a global standard metric that summarizes all direct and indirect greenhouse gas emissions in terms of carbon dioxide (CO2). To draw comparisons, the findings from the literature were also noted. The analysis of both PV strings was carried out in the manner described below [18, 19]:

where \(x_{{{\text{CO}}_{{2}} }}\) indicates the amount of CO2 generated over a specific period of time \(\left( {\frac{{kgCO_{2} }}{time}} \right)\), and \(y_{{{\text{CO}}_{{2}} }}\) represents the carbon dioxide emission quantity \(\left( {\frac{{kgCO_{2} }}{kWh}} \right)\) for the reference energy system. Under normal conditions, the emissions to the natural environment for the production of a PV module are in the 29 to 35 \(\left[ {\frac{{gCO_{2} }}{kWh}} \right]\) range. In this study, the approximate amount equivalent to 32 \(\left[ {\frac{{gCO_{2} }}{kWh}} \right]\) was selected to simplify the computations. Pout denotes the energy produced by the system, and tworking denotes the system functional time.

Exergoenvironmental analysis

It is feasible to undertake an exergy study of the environmental interaction of the PV power system throughout the production process. Similarly, 'exergo-environmental' refers to the process of analyzing a PV power-generating system in conjunction with exergy, environment, and working time. The primary goal here is to reduce global emissions while boosting the effectiveness of the parts of the PV system. The computation makes use of exergy output[18, 19]:

Energoenviroeconomic analysis

The assessment of the cost of carbon dioxide released by a PV panel to the environment will provide a comprehensive perspective of the energy, environmental, and cost evaluations. The equation of the analysis called 'EnergoEnviroEconomic' or 'enviroeconomic' is as follows [18, 19]:

where \(C_{\text{CO}_{2}}\) is the ecological cost savings factor, \(c_{\text{CO}_{2}}\) is the price of reduced CO2 emissions per tCO2, and xCO2 is the CO2 emission reduction annually (tCO2/year). If a customer.

Selects unit power and wastage from inefficient home appliances is roughly 20%, the transferred power must be 1*(1- 0.2) = 1.25 units.

Depending on each country's legislation, the price of carbon emissions varies; it changes between $13 and $16 per ton of CO2 produced ($13–16 per CO2 ton). The quantity considered in this investigation is $0.015 per kilogram [18, 19].

Exergoenviroeconomic analysis

Considering exergy, one of the study's primary parameters, the environmental economic evaluation is carried out similarly to energy-based analysis, but exergy is utilized rather than energy as follows [18, 19]:

Thus, the parameter \(C_{{{\text{ex, CO}}_{{2}} }}\) findings offer statistics on the exergetic expense of CO2.

Exergoeconomic analysis

The exergoeconomic parameter (Rex and Ren) is the exergy gain or loss ratio to the annual cost. While it is aimed to reduce the responsible one by estimating the exergy losses of the energies of the system parts, it is also intended to maximize the exergy output in the calculations based on the exergy gain. The environmental economic analysis controls the pollution caused by a system to its environment and promotes the use of renewable energy technology for the future. In general, the exergy losses of various components are calculated, and the component responsible for the exergy loss is determined. In other words, exergoeconomic analysis uses exergy and economic analysis approaches to enhance the efficiency of energy systems. To increase exergy efficiency, it is necessary to analyze exergoeconomic parameters accurately. The optimal design of power generation systems can be achieved by discussing cost and exergy issues jointly.

There are energy (Enloss) and exergy losses (Exloss and Exdest) during the energy production process of PV power systems. It is an exergoeconomic analysis that describes the watt-dollar cost of a PV power system together with economic and energy-exergy analyzes. For this reason, the energy and exergy analyzes of the PV power system are completed, and then the exergoeconomic analysis should be performed. It cannot be generated or destroyed due to the principle of energy conservation. Exergy, on the other hand, will be consumed in any process owing to irreversibility and is thus subject to a non-conservation law. Because of this, the general equilibrium equation is as follows[18, 19]:

The output terms can be rewritten as.

where Ex;out is overall exergy gain, Ex;cons is exergy consumption and Ex;acc is exergy accumulation.

To facilitate the computations, there are two kinds of thermodynamical losses: Len and Lex. Len represents energy-based loss, while Lex represents exergy-based loss.

The energy balance equation can be used to express the energy loss rate (Len) of a thermodynamic system as follows [17]:

According to Rosen & Dincer [1], a variable R is identified as the ratio of energy loss rate to exergy. First, in terms of exergoeconomical energy loss rates:

Then, for exergoeconomical exergy loss rates:

The 'Conclusions and Discussions' section contains details on the Net Present Value (NPV) (in Eq. 24 and 25) calculations. Table 3 contains the assumptions related to the economic evaluation of the grid-tied PV system.

Uncertainty analysis

It is essential to perform an uncertainty analysis of the devices used in experimental studies to prove the accuracy of the data obtained. This step is often overlooked, but it is crucial to ensure that the results are reliable. By acknowledging the potential limitations of the devices, we can confidently present our findings and support our conclusions with credible evidence.

The general form for expressing experimental uncertainty before scientific study is as follows:

Table 4 presents the uncertainty results and measured values. The analysis shows that all parameters have an uncertainty of less than 2%, which demonstrates the high reliability of the experimental measurement data [23, 24].

Results and discussions

This section deals with an in-depth exploration of the results derived from a comprehensive comparative analysis, including the investigation of energy (1E), exergy (2E), environmental (3E), and economic (4E) factors and their results. It also includes detailed evaluations of the impact of natural dust accumulation on the photovoltaic arrays within a grid-connected PV power plant, specifically located at OMU Technopark, Samsun, during the months of June, July, and August.

In order to ensure the accuracy and validity of the results, a methodologically well-established approach was adopted, involving the selection of two sets of PV module arrays, each consisting of identical quantities, for controlled experimental observations. Over the course of three months, careful scheduling was followed, with two cloudless and sunny days scheduled each week to provide optimal conditions for data collection and analysis, thereby contributing to the accuracy and reliability of the results obtained.

In this context, the resulting findings not only shed light on the nuances of economic viability, energy efficiency, and exergy performance but also provide valuable insights into the intricate interplay between environmental factors and operational parameters. Through a systematic examination of the collected data, accompanied by rigorous calculations and careful comparisons, a comprehensive understanding of the underlying dynamics governing the performance of the PV arrays under consideration is achieved.

In addition, the comprehensive analyzes presented herein serve as a fundamental framework for informed decision-making processes, guiding stakeholders in the formulation of strategic initiatives aimed at optimizing the operational efficiency and sustainability of grid-connected PV systems. By elucidating the multifaceted effects of natural dust deposition and its impact on overall performance metrics, this study contributes significantly to the advancement of knowledge in the field, paving the way for future research efforts and practical applications aimed at enhancing the resilience and effectiveness of renewable energy technologies.

Energy (1E) and exergy (2E) assessment

As mentioned earlier, global solar irradiation (IS), maximum generated power (Pm), maximum voltage (Vm), maximum current (Im), PV module temperature (Tmod), and ambient temperature (Ta) data were recorded for the selected days. Figures 4a, b clearly demonstrate the superior performance of cleaned PV arrays over a 12-week period. The power loss rate of the uncleaned arrays (P-loss-rate-dirty) was significantly higher than that of the cleaned arrays (P-loss-rate-clean), as shown in the data. Uncleaned PV arrays consistently exhibit elevated temperatures (Tmod) compared to cleaned arrays. This observation suggests that accumulated dirt on the arrays acts as an insulating layer, trapping heat and elevating the temperature of the cells. Throughout the entirety of the observation period, the cleaned PV arrays consistently demonstrate diminished power loss rates in comparison to their uncleaned counterparts. This highlights the positive impact of cleaning procedures on the arrays' ability to convert solar energy into electrical power. The uncleaned arrays exhibit a notably higher power production loss rate (P-loss-rate) compared to the cleaned ones. This provides strong evidence that the accumulation of dirt reduces the efficiency of PV arrays, leading to a decrease in power output.

In June, power loss rates for cleaned arrays ranged from 9.41% to 10.02%, while for uncleansed arrays, the range was approximately from 12.44% to 19.03%. Cleaned arrays consistently outperformed uncleaned arrays in terms of power loss rates, and this trend continued in the following months of July and August. The power loss rate difference (P-loss-rate-dirty minus P-loss-rate-clean) between uncleaned and cleaned arrays is a clear indicator of the effectiveness of cleaning procedures. A larger difference indicates that cleaning has a greater impact on improving array performance, especially during months with high solar radiation. Temperature and power loss rates vary across different months, as observed. In June and July, both rates tend to be higher compared to August, indicating that seasonal factors may affect array performance.

The data clearly shows that cleaning the arrays at the beginning of each month leads to consistently higher power output values compared to non-cleaned arrays. These results are based solely on the objective data collected, highlighting the importance of regular cleaning to maintain optimal performance. The Pm values for the cleaned arrays during the summer months of June, July, and August were slightly higher, ranging from 28.47 kW to 31.12 kW, while the dirty arrays ranged from 27.01 kW to 30.05 kW. The dirty PV arrays caused a decrease in performance ranging from 3.03% to 4.25%. It is crucial to consider the decrease in solar irradiance (IS) from 965 W m−2 to 853 W m−2 as the angle of incidence increases toward the end of August, with the highest value occurring in June, when calculating the power loss rate. To accurately assess the situation, this variation in solar irradiance (IS) must be taken into account. The rate of power loss is directly proportional to the ambient temperature of the PV power system installation. The power loss rate is lower in June and higher in August.

The exergy (2E) analysis demonstrates the superior performance of the 'cleaned-Array' photovoltaic (PV) array over the 'dirty-Array' under varying ambient temperature (Ta) (Fig. 5a) and solar irradiation (IS) (Fig. 5b) conditions, as illustrated in Fig. 5. With an exergy efficiency of 16.08% after cleaning, the 'cleaned-Array' outperformed the 'dirty-Array', which only achieved an efficiency of 13.65% during the same assessment period. Over time, the exergy efficiency of both arrays converged, with the 'cleaned-Array' reaching 13.33% and the 'dirty-Array' reaching 12.04% by the conclusion of August. This convergence persisted despite fluctuations evident in both cleaned and uncleaned PV strings, as illustrated in Figs. 5a, b.

Meteorological factors have a significant impact on the trends of exergy efficiency. The dirty counterpart had an exergy efficiency ranging from 12.41% to 13.65% in June. The exergy efficiency of the cleaned PV array ranged from 14% to 16.08% in June, and 13.33% to 14.51% in August, which was characterized by higher ambient temperatures. Please refer to Figs. 5a, b for more details. The exergy efficiency curves for both PV arrays demonstrate a lower efficiency in June compared to August, which is inversely correlated with solar radiation and ambient temperature.

It is a well-established fact that there is a decrease in exergy efficiency with increasing ambient temperature, regardless of whether the PV arrays are cleaned or uncleaned. The data shows that in June, exergy efficiency drops as the environmental temperature rises for both cleaned and dirty cells, but the drop is greater for dirty cells. This trend continues in July and August, with the difference in efficiency between cleaned and dirty cells becoming more pronounced. Exergy conversion rate drops as environmental temperature rises due to factors such as increasing resistance in PV cells, decreasing electron mobility, and increasing thermal losses. It is important to note that this decrease in efficiency is a well-known phenomenon. It is crucial to consider these factors when designing and operating PV systems to ensure optimal performance. Furthermore, losses caused by debris, dirt, or other impurities on the surface of PV arrays can also reduce exergy efficiency.

The sun irradiation (IS) ranges from approximately 99.18–113.16% across the periods, while the difference in Meanwhile, the percentage difference in exergy efficiency between cleaned and dirty panels varies from around 1.28–2.43%, as seen in Fig. 5a. Generally, higher sun irradiation corresponds to higher exergy efficiency values for both cleaned and dirty panels.

Percentage values illustrate changes in solar irradiation (IS) and exergy efficiency, highlighting the key role of panel cleanliness in optimizing energy conversion. Figures 5a, b show that ambient temperature (Ta) negatively affects the exergy efficiency of both clean and dirty PV arrays, with a more pronounced effect on the latter. Consistent cleaning and monitoring are critical to mitigate these effects and ensure maximum performance.

Environmental (3E) assessment

Transitioning to renewable energy sources, rather than relying on fossil fuels, offers a sustainable solution for reducing greenhouse gas emissions. Our study provides a precise quantification of carbon dioxide, a pivotal element in environmental discourse. We achieve accurate estimations of equivalent CO2 emissions through detailed analysis of energy and exergy data from PV systems. The research's robustness is demonstrated by the thorough examination of both energy and exergy-based environmental and economic parameters, highlighting its exceptional reliability. This comprehensive approach significantly enhances our understanding of sustainability dynamics. Regarding the energy and energy output of the cleaned and uncleaned PV arrays, Tables 5 and 6 illustrate the CO2 emission reduction per month (tCO2) and environmental cost reduction per month ($), respectively.

Tables 5 and 6 show the CO2 emission reduction (measured in tons) and environmental cost reduction (measured in USD) per month for the energy and energy output of the cleaned and uncleaned PV arrays, respectively. In June, cleaning the PV arrays resulted in a reduction of 21.76 kg of CO2 emissions compared to not cleaning, followed by reductions of 17.92 kg and 43.68 kg in July and August, respectively. These reductions are consistent across both energy and exergy analyzes, highlighting the impact of cleaning on environmental sustainability. Notably, the largest reductions in CO2 emissions occurred in August, with both cleaned and uncleaned PV arrays showing significant savings.

The difference in environmental cost reduction between cleaned and uncleaned PV modules is evident throughout the observation period. In June, the cleaned PV modules show a 16.5% reduction in environmental costs compared to their unclean counterparts, with values of $2.33 and $2.00, respectively. Similarly, in July, a reduction of 12.17% is observed for cleaned modules, with a value of $2.49 compared to $2.22 for uncleaned modules. August shows a consistent pattern, with cleaned modules showing a 10.76% reduction in environmental costs, amounting to $6.69, as opposed to $6.04 for uncleaned arrays.

In addition, the Exergy Environmental Economic perspective provides comparable results. In June, cleaned PV arrays showed a reduction of 15.68%, with a monetary value of $2.14, while uncleaned arrays showed a value of $1.85. July shows a reduction of 12.38% for cleaned arrays, valued at $2.27, compared to $2.02 for unclean arrays. Furthermore, in August, cleaned arrays show a reduction of 10.87% with a value of $6.02 while uncleaned arrays showed a value of $5.43, see Table 6.

Throughout the study, cleaned PV modules consistently showed greater CO2 emission reductions, resulting in greater environmental cost savings. Notably, the maximum return on reduced greenhouse gas equivalent savings was observed in August, reflecting the influence of electrical energy generation on greenhouse gas reduction. These findings are consistent with existing literature and are discussed further in the following sections.

In short, regular cleaning of PV modules consistently results in higher environmental cost reductions in both energy and exergy categories, underscoring the economic benefits of maintenance and cleaning practices.

Exergoeconomic analysis

This section discusses the impact of natural dirt deposition over PV panel surfaces on exergoeconomic parameters. Firstly, Len and Lex, the main components of exergoeconomic analysis, and NPV are defined, and computations and comparisons are made. The required data were taken around 12:30 p.m. when the sun was at its highest point due to high solar irradiance (IS) values, twice a week, on clear and sunny days, in June, July, and August for 12 weeks.

Since the grid-connected PV system was installed within the scope of the university project, the estimated values of some components of the PV system based on average costs were considered in the NPV calculations. In this study, the price list provided in the latest edition (Q1 2022) of US-NREL was used to calculate the cost of a PV system [28]. This includes the cost of capital and the PV power system, modules, racking, design and construction, testing of system components, training of staff technicians, and commissioning of the PV power system. The expected life of the four inverters in the power generation of the PV power plant in this work is 10 years, therefore it is assumed that the system will be replaced twice during its 25-year life. The NPV has been calculated to be valid for each year [2]. The replacement costs of some parts of the PV power system, which are expected to last for 25 years, including inverters, cleaning costs, operating costs, and maintenance costs over the lifetime are also considered.

As previously explained, the R-value serves as a fundamental indicator within the exergo-economic analysis of photovoltaic (PV) power systems, representing the ratio between the thermodynamic loss rate (L) and the net present value (NPV). The determination of the thermodynamic loss rate, denoted as Lex, for the PV power system was carried out meticulously using Eqs. 22 and 23. Len, derived from the difference between Een- input and Een- output, facilitated the quantification of Lex. Furthermore, given the equivalence of Lex and Eex, the exergy loss rate was accurately calculated, ensuring the accuracy of the analysis.

The Rex-dirt values range from approximately 0.416–0.485 W $−1 over the recorded weeks, with the ambient temperature (Ta) showing relative stability between 293.10 K and 301.40 K throughout the observations, implying consistent external conditions. Comparing the Rex-clean (Exergoeconomic Parameters) values with their Rex-dirt counterparts, a consistent increase in efficiency after cleaning is evident. Notable examples include the first week (jn-1), where Rex-dirt is recorded at 0.42335 W $−1 and then increases slightly to 0.42381 W $−1 after cleaning. This trend continues through most weeks, with notable instances such as week jn-3, where Rex-dirt records 0.48033 W $−1 and post-cleaning Rex escalates to 0.48301 W $−1.

It is relevant to note the variance in the magnitude of the improvement. In particular, in cases such as week Aug-1, the improvement is more pronounced, with Rex- dirt recorded at 0.41621 W $−1, while after cleaning, Rex increases significantly to 0.41127 W $−1. When comparing data for cleaned and uncleaned PV systems, attention is drawn to exergo-economic parameters such as Rex and solar irradiance, as shown in Fig. 6. The analysis of Rex values shows a marginal superiority of cleaned PV systems over their uncleaned counterparts. For example, during the week of June 1, the Rex for the cleaned system was 0.42381 W $−1 compared to 0.42335 W $−1 for the unclean system. Similarly, during the week of June 2, Rex for the cleaned system was 0.47376 W $−1, compared to 0.47489 W $−1 for the uncleaned system.

Furthermore, while solar irradiance varies from week to week, there is no consistent pattern that indicates a direct correlation between solar irradiance and the cleaning status of PV systems. This implies that the increase in Rex attributed to cleaning is not solely due to variations in solar radiation. Overall, the data confirms that cleaning the PV system results in a small but noticeable performance improvement, as evidenced by higher values of the exergy-economic parameter Rex in cleaned systems compared to their unclean counterparts.

The energy-economic and exergy-economic losses of the PV power system are meticulously presented in a comprehensive graphical format. Notably, both energy and exergy losses show a marginal increase in June, peaking toward the end of the month. The data clearly shows that the losses decrease proportionally with ambient temperature (Ta) and solar irradiance (IS), reaching their lowest point at the end of August, as shown in Figs. 6a, b. This analysis underscores the complex interplay between environmental variables and system performance and highlights the dynamic nature of energy and exergy losses throughout the observed period.

Comparisons of the result with previous work

The present study provides a comprehensive analysis of the effects of dust accumulation on photovoltaic (PV) module surfaces, with particular emphasis on the impact on power generation efficiency and greenhouse gas (GHG) emissions. A controlled investigation was conducted at the PV power plant of Samsun OMU-Techno Park to evaluate the influence of dust accumulation on PV module surfaces. The results were compared with previous research efforts to elucidate the significance of the findings. Cleaned PV arrays exhibited power loss ratios ranging from 7.72% to 17.05%, while dirty arrays exhibited higher power loss ratios ranging from 13.2% to 21.30%. Instantaneous production peaked at 32.19 kW, with an associated exergy efficiency of 15.03%. The results underscore the critical role of solar radiation in determining the energy efficiency and degradation of PV systems, regardless of surface cleanliness. Exergy losses were observed to vary from 144.099 kW to 144.9 kW for cleaned and dirty arrays, respectively, with corresponding efficiencies ranging from 12.03% to 16.08% and 13.33% to 16.08%, respectively, influenced by solar irradiation and temperature fluctuations.

Table 7 presents a detailed overview of the primary research and results on the effects of the formation of soiling on the surface of PV panels, as well as the effects on the efficiency of PV power generation and the methods of analysis.

Methodologies focusing on energy and exergy efficiency have been refined to integrate economic and environmental considerations, such as the 5E-7E framework. These findings are consistent with previous studies by Juaidi et al. (2022), Abdallah et al. (2022), Zhao et al. (2023), Shaik et al. (2023), Kamal et al. (2023), El-wahhab et al. (2023), Alkharusi et al. (2024), and Fodah et al. (2024), which collectively highlight the negative impact of various contaminants on PV module performance. Here are some recent studies that are briefly mentioned below:

According to Juaidi et al. [7], inadequate cleaning resulted in a 9.99% decrease in performance over a period of seven months. It is important to address this issue promptly to prevent further decline in performance. Abdallah et al. [8], conducted over twelve months in climates outside of Palestine, demonstrated efficiency losses ranging from 8.98% to 13.1% due to dust accumulation. The research highlights the universal impact of environmental factors on PV system efficiency. Zhao et al. [11] investigated the performance of PV modules under various conditions and found a significant decrease in maximum power output (32.2%) with increasing sand accumulation, which was particularly exacerbated at higher wind speeds and tilt angles. They emphasize the need to consider multiple environmental variables when assessing PV system performance. Shaik et al. [10] observed significant losses in PV panel efficiency due to bird droppings compared to coal dust, with minimal effects from tilt angles. It is crucial to understand the specific characteristics of pollutants and their impacts on PV panel efficiency. In their study, Kamal et al. [12] found that dirt accumulation can significantly reduce the maximum power output of PV arrays, with a reduction of up to 31% observed. El-Wahhab et al. [9] conducted a comprehensive investigation of the impact of dirt deposition on PV efficiency, analyzing various parameters such as temperature, current, voltage, and efficiency, and found significant reductions in output power and efficiency. In the study conducted by Alkharusi et al. [14], it was found that contamination of PV modules resulted in a significant reduction in power generation. According to Fodah et al. [13], bird guano accumulation on PV modules can cause localized hot spots and reduce power output. Sudhakar and Srivasta [30] observed variable energy efficiencies ranging from 6 to 9% and exergy efficiencies ranging from 8 to 10% in a 36 W PV module through experimental data analysis. Bayat and Özalp [17] reported a maximum exergy efficiency of about 18% in a 130 W PV module. Exergo-economic analysis showed energy losses ranging from 0.06 to 0.45 W $−1, and combined exergy losses and destruction varied from 0.05 to 0.43 W $−1. Izgi and Akkaya [16] used the EXCEM model to evaluate thermo-economic parameters and obtained values of 0.222 W $−1 and 0.134 W $−1 for August and April, respectively, and 0.214 W $−1 and 0.129 W $−1 from the exergo-economic analysis. Sreenath et al. [18] studied a 5000 kW PV system and observed exergy efficiencies ranging from 11.35% to 12.65%. They also quantified parameters such as GHG mitigation (4291 tCO2/year), enviroeconomic impact (42,916 USD), energoeconomic efficiency (0.0147 kWh USD−1), and exergoeconomic efficiency (1.096 kW USD−1). Manjunath et al. [20] found energetic and exergetic efficiencies of about 25.2% and 32.4%, respectively, for a 50 W PV module. Kuczynski and Chliszcz [22] found energy efficiencies of 7.7% for monocrystalline cells and 2.93% for amorphous PV modules during the summer months, with corresponding exergy efficiencies of 3.0% and 0.7%, respectively.

Collectively, these studies contribute to the understanding of how various environmental factors, including dust accumulation, sand deposition, bird droppings, and other contaminants, affect the efficiency and performance of PV modules. By studying these factors under different climatic conditions and experimental setups, researchers can gain valuable insights into the complex dynamics at play and develop strategies to mitigate their adverse effects on PV system performance.

Conclusions

A controlled experiment was conducted in Samsun Province OMÜ-Technopark to investigate the impact of dust accumulation on solar PV modules. Data was collected and recorded twice a week during June, July, and August on cloudless and sunny days for the necessary calculations. The results of the experiment include energy, exergy, environmental economy, and exergoeconomic analyzes. A comparison of PV arrays that have been cleaned versus those that have not been cleaned reveals significant differences in several parameters. Based on the data, it can be confidently stated that regular cleaning of PV arrays is essential for optimal performance. The results of this comparison are summarized below:

The data shows that cleaned PV arrays have lower power loss rates, ranging from 9.41% to 10.02%, compared to uncleaned PV arrays, with power loss rates ranging from 12.44% to 19.03%. This indicates a significant difference of 3.03–9.01%. These results demonstrate a significant improvement in performance for cleaned PV arrays, with consistently lower power loss rates than uncleaned PV arrays.

It is evident that cleaned PV arrays consistently exhibit slightly higher Pm values compared to uncleaned PV arrays during the summer months of June, July, and August. Specifically, the Pm values for cleaned PV arrays ranged from 28.47 kW to 31.12 kW, while for uncleaned PV arrays, the range was from 27.01 kW to 30.05 kW, resulting in a difference of about 1.46 kW.

In June, the dirty counterpart had an exergy efficiency ranging from 12.41% to 13.65%, while the cleaned PV array ranged from 14% to 16.08%. The exergy efficiency of the cleaned PV array ranged from 14% to 16.08% in June, and 13.33–14.51% in August, which was characterized by higher ambient temperatures, resulting in a difference between 1.59–2.43%.

Regular cleaning of photovoltaic (PV) systems can significantly reduce carbon dioxide (CO2) emissions. The study shows a decrease of 21.76 kg in June, 17.92 kg in July, and 43.68 kg in August.

Cleaned modules consistently show a reduction in environmental costs compared to uncleaned modules. For example, in June, cleaned modules exhibited a 16.5% reduction in environmental costs compared to uncleaned modules, with values of $2.33 and $2.00, respectively. Similar patterns were observed in July and August, further emphasizing the economic advantages of cleaning PV arrays.

In conclusion, the comparison between cleaned and uncleaned PV arrays demonstrates the positive impact of regular cleaning on performance, efficiency, and economics. These findings emphasize the importance of implementing proactive maintenance practices to optimize the performance of PV systems and maximize their economic and environmental benefits.

As a continuation of this study, the following recommendations can be made:

-

To extend this study, the long-term effects of dust deposition on PV panel performance should be evaluated by extending the study period beyond three months. This will allow a comprehensive capture of seasonal variations.

-

The effect of the tilt angle of the PV panel on dust accumulation and cleaning efficiency could be analyzed, taking into account the optimal tilt angle for different regions and seasons.

-

Thirdly, to generalize the results of this study, location-specific cleaning requirements can be determined by comparing PV systems installed in different geographical locations in Samsun.

-

Another extension of the study can be by providing policy recommendations or guidelines for PV system owners and stakeholders regarding optimal maintenance practices, including cleaning frequency, methods, and cost–benefit considerations, to promote sustainable energy production and maximize return on investment.

Abbreviations

- A :

-

Area (m2)

- E :

-

Energy (W)

- Ex :

-

Exergy (W)

- h ca :

-

Heat transfer coefficient (W.m−2.K−1)

- I :

-

Electric current (A)

- I S :

-

Solar radiation [W m−2]

- L en :

-

Energy loss rate

- L ex :

-

Exergy loss rate

- P :

-

Electrical power (W)

- P out :

-

Output power [W]

- R :

-

The function uncertainty

- R :

-

Exergoeconomic parameter

- T :

-

Temperature (0C and K)

- V :

-

Electrical voltage (V)

- v w :

-

The local wind speed

- w 1 ,w 2 ,w n :

-

Uncertainty values in the independent metrics

- W R :

-

Total uncertainty (%)

- \(y_{\text{CO}_{2}}\) :

-

CO2 emission value of photovoltaic

- \(x_{\text{CO}_{2}}\) :

-

Amount of CO2 emission

- t working :

-

Working hours of the photovoltaic

- C :

-

Cost

- Ψ :

-

Exergy efficiency

- η :

-

Energy efficiency

- a :

-

Ambient

- acc :

-

Accumulation

- cons :

-

Consumption

- dest :

-

Destructive

- ex :

-

Exergy

- en :

-

Energy

- el :

-

Electrical

- In :

-

İNput

- Out :

-

Output

- m :

-

Maximum

- mod :

-

Module

- l :

-

Loss

- th :

-

Thermal

- NPV:

-

Net present value

- PV:

-

Photovoltaic

- NOST:

-

Nominal operating cell temperature [K

References

Sheikholeslami M, Khalili Z. Investigation of nanofluid cooling influence on energy performance of photovoltaic-thermoelectric module. J Therm Anal Calorim. 2024;149(1):495–503. https://doi.org/10.1007/s10973-023-12710-3.

Selimefendigil F, Okulu D, Oztop HF. Three dimensional numerical study of PV module cooling by using thermoelectric effects and nano-enhanced confined multiple slot jet impingement. Int J Heat Mass Transf. 2023;221(September):2024. https://doi.org/10.1016/j.ijheatmasstransfer.2023.125093.

Özkalay E, Valoti F, Caccivio M, Virtuani A, Friesen G, Ballif C. The effect of partial shading on the reliability of photovoltaic modules in the built-environment. Accept Publ EPJ Photovoltaics. 2024;7:1–17.

Hachicha AA, Al-Sawafta I, Said Z. Impact of dust on the performance of solar photovoltaic (PV) systems under United Arab Emirates weather conditions. Renew Energy. 2019;141:287–97. https://doi.org/10.1016/j.renene.2019.04.004.

Darwish ZA, Sopian K, Fudholi A. Reduced output of photovoltaic modules due to different types of dust particles. J Clean Prod. 2021. https://doi.org/10.1016/j.jclepro.2020.124317.

Ali Sadat S, Faraji J, Nazififard M, Ketabi A. The experimental analysis of dust deposition effect on solar photovoltaic panels in Iran’s desert environment. Sustain Energy Technol Assess. 2021;47:45. https://doi.org/10.1016/j.seta.2021.101542.

Juaidi A, Muhammad HH, Abdallah R, Abdalhaq R, Albatayneh A, Kawa F. Experimental validation of dust impact on-grid connected PV system performance in Palestine: an energy nexus perspective. Energy Nexus. 2022;6:78. https://doi.org/10.1016/j.nexus.2022.100082.

Abdallah R, et al. The effects of soiling and frequency of optimal cleaning of PV panels in palestine. Energies. 2022;15:78. https://doi.org/10.3390/en15124232.

El-wahhab GGA, Abdelwahab TAM, Taha Osman YKO, Abuhussein MFA, Fodah AEM, Ali KAM. Performance evaluation of solar panels under different dust accumulation conditions using thermography: focusing on PV temperature variation. Mater Renew Sustain Energy. 2023;12(3):247–55. https://doi.org/10.1007/s40243-023-00246-3.

Shaik S, et al. “Experimental analysis on the impacts of soil deposition and bird droppings on the thermal performance of photovoltaic panels”, case stud. Therm Eng. 2023. https://doi.org/10.1016/j.csite.2023.103128.

Zhao M, et al. Effect of sand and dust shading on the output characteristics of solar photovoltaic modules in desertification areas. Energies. 2023. https://doi.org/10.3390/en16237910.

Kamal R, Abdel-Salam M, Nayel M. Performance characteristic of a PV module as influenced by dust accumulation: theory versus experiment. J Eng Appl Sci. 2023;70(1):1–22. https://doi.org/10.1186/s44147-023-00181-0.

Fodah AEM, Abdelwahab TAM, Ali KAM, Osman YKOT, Abuhussein MFA, El-wahhab GGA. Performance evaluation of solar photovoltaic panels under bird droppings accumulation using thermography. MRS Energy Sustain. 2024. https://doi.org/10.1557/s43581-024-00081-7.

Alkharusi T, Huang G, Markides CN. Characterisation of soiling on glass surfaces and their impact on optical and solar photovoltaic performance. Renew Energy. 2023;220(May):2024. https://doi.org/10.1016/j.renene.2023.119422.

Joshi AS, Dincer I, Reddy BV. Thermodynamic assessment of photovoltaic systems. Sol Energy. 2009. https://doi.org/10.1016/j.solener.2009.01.011.

Izgi E, Akkaya YE. Exergoeconomic analysis of a solar photovoltaic system in İstanbul, Turkey. Turkish J Electr Eng Comput Sci. 2013;21(2):350–9. https://doi.org/10.3906/elk-1108-25.

Bayat M, Ozalp M. Energy, exergy and exergoeconomic analysis of a solar photovoltaic module. Elsevier. 2018. https://doi.org/10.1016/B978-0-12-813734-5.00022-6.

Sreenath S, Sudhakar K, AF Y. 7E analysis of a conceptual utility-scale land-based solar photovoltaic power plant. Energy. 2021. https://doi.org/10.1016/j.energy.2020.119610.

Yaghoubirad M, Azizi N, Ahmadi A, Zarei Z, Moosavian SF. Performance assessment of a solar PV module for different climate classifications based on energy, exergy, economic and environmental parameters. Energy Rep. 2022;8:68–84. https://doi.org/10.1016/j.egyr.2022.05.100.

Manjunath C, Reddy J, Reddy KSR, Kumar IRG, Sanketh S. Energy, exergy performance and analysis of 50w solar photovoltaic module. Mater Today Proc. 2022. https://doi.org/10.1016/j.matpr.2021.12.209.

Ozturk MC, Dogan B, Yesilyurt MK. Energy, exergy, sustainability, and economic analyzes of a grid-connected solar power plant consisting of bifacial PV modules with solar tracking system on a single axis. Sci Technol Energy Transit. 2023. https://doi.org/10.2516/stet/2023015.

Kuczynski W, Chliszcz K. Energy and exergy analysis of photovoltaic panels in northern Poland. Renewable Sustainable Energy Reviews. 2023. https://doi.org/10.1016/j.rser.2022.113138.

Bayrak F, Oztop HF, Selimefendigil F. Experimental study for the application of different cooling techniques in photovoltaic (PV) panels. Energy Convers Manag. 2020. https://doi.org/10.1016/j.enconman.2020.112789.

Şirin C, Selimefendigil F, Öztop HF. Performance analysis and identification of an indirect photovoltaic thermal dryer with aluminum oxide nano-embedded thermal energy storage modification. Sustain. 2023. https://doi.org/10.3390/su15032422.

Maatoug S, et al. Pulsating multiple nano-jet impingement cooling system design by using different nanofluids for photovoltaic (PV) thermal management. Case Stud Therm Eng. 2022. https://doi.org/10.1016/j.csite.2022.102650.

Maatoug S, et al. Pulsating multiple nano-jet impingement cooling system design by using different nanofluids for photovoltaic (PV) thermal management. Energy Convers Manag. 2024;221(1):495–503. https://doi.org/10.1016/j.ijheatmasstransfer.2023.125093.

Petela R. An approach to the exergy analysis of photosynthesis. Sol Energy. 2008. https://doi.org/10.1016/j.solener.2007.09.002.

V. Ramasamy et al., “U . S . Solar photovoltaic system and energy storage cost benchmarks, with minimum sustainable price analysis : Q1 2022 U . S . Solar Photovoltaic system and energy storage cost benchmarks, with minimum sustainable price analysis : Q1 2022

Manjunath C, Reddy J, Reddy KSR, Kumar IRG, Sanketh S. Energy, exergy performance and analysis of 50w solar photovoltaic module. Mater Today Proc. 2022;54:531–6. https://doi.org/10.1016/j.matpr.2021.12.209.

Sudhakar K, Srivastava T. Energy and exergy analysis of 36 W solar photovoltaic module. Int J Ambient Energy. 2014;35(1):51–7. https://doi.org/10.1080/01430750.2013.770799.

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK). This research received no external funding.

Author information

Authors and Affiliations

Contributions

Vedat Keskin is the only author and is responsible for the entire work.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare no conflict of interest.

Informed consent statement

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Keskin, V. Energy- and exergy-based economical and environmental (4E) evaluation of the influence of natural pollutants on PV array performance. J Therm Anal Calorim (2024). https://doi.org/10.1007/s10973-024-13160-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10973-024-13160-1