Abstract

Electric motor is a critical component of an electric vehicle, and proper thermal management is essential for its efficient and reliable operation. As the electric vehicle industry continues to evolve, there is a growing demand for electric motors that can deliver superior performance and high efficiency. These motors are expected to be more powerful and provide higher torque, speed, and power density to meet the performance requirements of electric vehicles; therefore, effective cooling is essential to maintain optimal motor temperature. Improper thermal management causes several issues in electric motors, including demagnetization of magnets, insulation materials aging, reduced efficiency, shorter lifespan, and motor burnout. This article presents a brief review of cooling techniques for electric motors through both numerical and experimental investigations. The researchers have evaluated various cooling techniques for electric motors, which can be broadly categorized as active cooling, passive cooling, and hybrid cooling techniques. This review highlights the temperature variations in different motor components when these cooling techniques are employed, along with the methods used to analyze the motor under different operating conditions and parameters. In conclusion, the paper recommends the most effective cooling techniques for electric motor components based on the analysis performed, providing reasons for their selection. Liquid cooling and passive cooling techniques are found to be efficient thermal management techniques for which the findings are elaborated in detail.

Similar content being viewed by others

Abbreviations

- AEA:

-

All electric aircraft

- AFPMSM:

-

Axial flux permanent magnet synchronous motor

- AIN:

-

Aluminum nitride

- ANN:

-

Artificial neural network

- BLDC:

-

Brushless DC motor

- CAD:

-

Computer-aided design

- CFD:

-

Computational fluid dynamics

- CHC:

-

Channel cooling

- DSC:

-

Direct slot cooling

- DWHX:

-

Direct winding heat exchanger

- EC:

-

Evaporative cooling

- ETC:

-

End tip cooling

- EV:

-

Electric vehicle

- FEA:

-

Finite element analysis

- FEPM:

-

Fully enclosed permanent magnet motor

- HP:

-

Heat pipe

- HTC:

-

Heat transfer coefficient in W m-2 K-2

- HWDS:

-

Highway driving schedule

- IM:

-

Induction motor

- IPM:

-

Interior permanent magnet

- IPMSM:

-

Interior permanent magnet synchronous motor

- JC:

-

Jacket cooling

- LPTN:

-

Lumped parameter thermal network

- PCM:

-

Phase change material

- PM:

-

Permanent magnet

- PMSM:

-

Permanent magnet synchronous motor

- RAVH:

-

Rotor axial vent hole

- RCPI:

-

Rotor cooling performance index

- RM:

-

Rounding module

- SAVH:

-

Stator axial vent hole

- SEME:

-

Straight embedded module enclosure

- SRM:

-

Synchronous reluctance motor

- UDDS:

-

Urban dynamometer driving schedule

- WJC:

-

Water jacket cooling

- °C:

-

Temperature in degree Celsius

- 2D:

-

2-Dimensional

- 3D:

-

3-Dimensional

- dT:

-

Temperature difference

- hp:

-

Horse power

- I :

-

Current in amp

- K :

-

Temperature in kelvin

- k :

-

Loss coefficient

- kW:

-

Power in kilowatts

- min:

-

Time in minutes

- s :

-

Time in seconds

- R :

-

Resistance in ohms

- σ :

-

Stefan-Boltzmann constant (W m-2 K-4).

- ε :

-

Emissivity of the surface

- ω :

-

Angular frequency (rad/s)

- β :

-

Steinmetz constant

- Cu:

-

Copper

- Iron:

-

Iron

- Ph:

-

Phase

References

Bilgin B, Emadi A. Electric motors in electrified transportation: a step toward achieving a sustainable and highly efficient transportation system. IEEE Power Electron Magaz. 2014;1:10–7. https://doi.org/10.1109/MPEL.2014.2312275.

Arbab N, Wang W, Lin C, et al. Thermal modeling and analysis of a double-stator switched reluctance motor. IEEE Trans Energy Convers. 2015;30:1209–17. https://doi.org/10.1109/TEC.2015.2424400.

Kahourzade S, Mahmoudi A, Ping HW, Uddin MN. A comprehensive review of axial-flux permanent-magnet machines. Can J Electr Comput Eng. 2014;37:19–33.

Gronwald PO, Kern TA. Traction motor cooling systems: a literature review and comparative study. IEEE Trans Transp Electrification. 2021;7:2892–913.

Gai Y, Kimiabeigi M, Chuan Chong Y, et al. Cooling of automotive traction motors: schemes, examples, and computation methods. IEEE Trans Industr Electron. 2019;66:1681–92. https://doi.org/10.1109/TIE.2018.2835397.

Wang X, Li B, Gerada D, et al. A critical review on thermal management technologies for motors in electric cars. Appl Therm Eng. 2022. https://doi.org/10.1016/j.applthermaleng.2021.117758.

Huynh TA, Hsieh MF. Improvement of traction motor performance for electric vehicles using conductors with insulation of high thermal conductivity considering cooling methods. IEEE Trans Magn. 2021. https://doi.org/10.1109/TMAG.2020.3021127.

Salameh F, Picot A, Chabert M, Maussion P. Parametric and nonparametric models for lifespan modeling of insulation systems in electrical machines. IEEE Trans Ind Appl. 2017;53:3119–28. https://doi.org/10.1109/TIA.2016.2635100.

Zhang X, Yang Q, Ma M, et al. A switched reluctance motor torque ripple reduction strategy with deadbeat current control and active thermal management. IEEE Trans Veh Technol. 2020;69:317–27. https://doi.org/10.1109/TVT.2019.2955218.

Polikarpova M, Ponomarev P, Lindh P, et al. Hybrid cooling method of axial-flux permanent-magnet machines for vehicle applications. IEEE Trans Industr Electron. 2015;62:7382–90. https://doi.org/10.1109/TIE.2015.2465354.

Fang G, Yuan W, Yan Z, et al. Thermal management integrated with three-dimensional heat pipes for air-cooled permanent magnet synchronous motor. Appl Therm Eng. 2019;152:594–604. https://doi.org/10.1016/j.applthermaleng.2019.02.120.

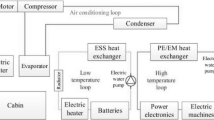

Li B, Kuo H, Wang X, et al. Thermal management of electrified propulsion system for low-carbon vehicles. Automot Innov. 2020;3:299–316. https://doi.org/10.1007/s42154-020-00124-y.

Gundabattini E, Kuppan R, Solomon DG, et al. A review on methods of finding losses and cooling methods to increase efficiency of electric machines. Ain Shams Eng J. 2021;12:497–505.

Yamazaki K, Fukushima N. Iron-loss modeling for rotating machines: comparison between bertotti’s three-term expression and 3-d eddy-current analysis. IEEE Trans Magn. 2010;46:3121–4. https://doi.org/10.1109/TMAG.2010.2044384.

Ionel D, Popescu M, Cossar C, McGilp MI, Boglietti A, Cavagnino A (2008) A general model of the laminated steel losses in electric motors with PWM voltage supply. In: IEEE Industry Applications Society Annual Meeting. IEEE

Luomi J, Zwyssig C, Looser A, Kolar JW. Efficiency optimization of a 100-W 500 000-r/min permanent-magnet machine including air-friction losses. IEEE Trans Ind Appl. 2009;45:1368–77. https://doi.org/10.1109/TIA.2009.2023492.

Huang Z, Fang J, Liu X, Han B. Loss calculation and thermal analysis of rotors supported by active magnetic bearings for high-speed permanent-magnet electrical machines. IEEE Trans Industr Electron. 2016;63:2027–35. https://doi.org/10.1109/TIE.2015.2500188.

Schwarz KK. Survey of basic stray losses in squirrel-cage induction motors. Proc Inst Electric Eng. 1964;111:1565–74.

Howey DA, Holmes AS, Pullen KR. Measurement and CFD prediction of heat transfer in air-cooled disc-type electrical machines. IEEE Trans Ind Appl. 2011;47:1716–23. https://doi.org/10.1109/TIA.2011.2156371.

Tüysüz A, Meyer F, Steichen M, et al. Advanced cooling methods for high-speed electrical machines. IEEE Trans Ind Appl. 2017;53:2077–87. https://doi.org/10.1109/TIA.2017.2672921.

Dong B, Wang K, Han B, Zheng S. Thermal analysis and experimental validation of a 30 kW 60000 r/min high-speed permanent magnet motor with magnetic bearings. IEEE Access. 2019;7:92184–92. https://doi.org/10.1109/ACCESS.2019.2927464.

Tikadar A, Kumar N, Joshi Y, Kumar S* (2020) Coupled electro-thermal analysis of permanent magnet synchronous motor for electric vehicles. In: 19th IEEE ITHERM Conference (ed) 19th IEEE ITHERM Conference. IEEE, pp. 249–256

Guo C, Long L, Wu Y, et al. Electromagnetic-thermal coupling analysis of a permanent-magnet in-wheel motor with cooling channels in the deepened stator slots. Case Stud Therm Eng. 2022. https://doi.org/10.1016/j.csite.2022.102158.

Nakahama T, Biswas D, Kawano K, Ishibashi F. Improved cooling performance of large motors using fans. IEEE Trans Energy Convers. 2006;21:324–31. https://doi.org/10.1109/TEC.2006.874245.

Galloni E, Parisi P, Marignetti F, Volpe G. CFD analyses of a radial fan for electric motor cooling. Therm Sci Eng Prog. 2018;8:470–6. https://doi.org/10.1016/j.tsep.2018.10.003.

Yangsoo Lee SH. Thermal analysis of induction motor with forced cooling channels. IEEE Trans Magn. 2000;36:1398–402. https://doi.org/10.1109/20.877700.

Baggu MM, Hess HL, Rink K (2005) Thermal modeling of “direct lamination cooling (DLC)” induction motor for hybrid electric vehicle applications. In: 2005 IEEE Vehicle Power and Propulsion Conference, VPPC. IEEE Computer Society, pp. 242–246

Kral C, Haumer A, Haigis M, et al. Comparison of a CFD analysis and a thermal equivalent circuit model of a TEFC induction machine with measurements. IEEE Trans Energy Convers. 2009;24:809–18. https://doi.org/10.1109/TEC.2009.2025428.

Ahmed F, Ghosh E, Kar NC (2016) Transient thermal analysis of a copper rotor induction motor using a lumped parameter temperature network model. In: 2016 IEEE Transportation Electrification Conference and Expo, ITEC 2016. Institute of Electrical and Electronics Engineers Inc.

Cavazzuti M, Gaspari G, Pasquale S, Stalio E. Thermal management of a formula E electric motor: analysis and optimization. Appl Therm Eng. 2019. https://doi.org/10.1016/j.applthermaleng.2019.113733.

Mezani S, Takorabet N, Laporte B. A combined electromagnetic and thermal analysis of induction motors. IEEE Trans Magn. 2005;41:1572–5. https://doi.org/10.1109/TMAG.2005.845044.

Boglietti A, Cavagnino A, Staton DA. TEFC induction motors thermal models: a parameter sensitivity analysis. IEEE Trans Ind Appl. 2005;41:756–63. https://doi.org/10.1109/TIA.2005.847311.

Sim K, Lee YB, Jang SM, Kim TH. Thermal analysis of high-speed permanent magnet motor with cooling flows supported on gas foil bearings: part I-coupled thermal and loss modeling. J Mech Sci Technol. 2015;29:5469–76. https://doi.org/10.1007/s12206-015-1148-0.

Aldaghi A, Banejad A, Kalani H, et al. An experimental study integrated with prediction using deep learning method for active/passive cooling of a modified heat sink. Appl Therm Eng. 2023. https://doi.org/10.1016/j.applthermaleng.2022.119522.

Grabowski M, Urbaniec K, Wernik J, Wołosz KJ. Numerical simulation and experimental verification of heat transfer from a finned housing of an electric motor. Energy Convers Manag. 2016;125:91–6. https://doi.org/10.1016/j.enconman.2016.05.038.

Kim C, Lee KS. Thermal nexus model for the thermal characteristic analysis of an open-type air-cooled induction motor. Appl Therm Eng. 2017;112:1108–16. https://doi.org/10.1016/j.applthermaleng.2016.10.197.

Kim C, Lee KS, Yook SJ. Effect of air-gap fans on cooling of windings in a large-capacity, high-speed induction motor. Appl Therm Eng. 2016;100:658–67. https://doi.org/10.1016/j.applthermaleng.2016.02.077.

Fawzal AS, Cirstea RM, Gyftakis KN, et al. Fan performance analysis for rotor cooling of axial flux permanent magnet machines. IEEE Trans Ind Appl. 2017;53:3295–304. https://doi.org/10.1109/TIA.2017.2675986.

Fawzal AS, Cirstea RM, Woolmer TJ, et al. Air inlet/outlet arrangement for rotor cooling application of axial flux PM machines. Appl Therm Eng. 2018;130:1520–9. https://doi.org/10.1016/j.applthermaleng.2017.11.121.

Chang CC, Kuo YF, Wang JC, Chen SL. Air cooling for a large-scale motor. Appl Therm Eng. 2010;30:1360–8. https://doi.org/10.1016/j.applthermaleng.2010.02.023.

Tanguy D, Harmand S, Pellé J, Yu R (2014) Erratum: Experimental study of oil cooling systems for electric motors (Applied Thermal Engineering). Appl Therm Eng 71

Lim DH, Kim SC. Thermal performance of oil spray cooling system for in-wheel motor in electric vehicles. Appl Therm Eng. 2014;63:577–87. https://doi.org/10.1016/j.applthermaleng.2013.11.057.

Cao J, Zhou B, Li D, et al (2022) Analysis of heat transfer and cooling structure of dual-waterway parallel axial flux permanent magnet synchronous motor for electric vehicles. In: Proceedings-2022 7th Asia Conference on Power and Electrical Engineering, ACPEE 2022. Institute of Electrical and Electronics Engineers Inc., pp. 992–997

Wang X, Li B, Huang K, et al. Experimental investigation on end winding thermal management with oil spray in electric vehicles. Case Stud Therm Eng. 2022. https://doi.org/10.1016/j.csite.2022.102082.

Tikadar A, Johnston D, Kumar N, et al. Comparison of electro-thermal performance of advanced cooling techniques for electric vehicle motors. Appl Therm Eng. 2021. https://doi.org/10.1016/j.applthermaleng.2020.116182.

Park MH, Kim SC. Thermal characteristics and effects of oil spray cooling on in-wheel motors in electric vehicles. Appl Therm Eng. 2019;152:582–93. https://doi.org/10.1016/j.applthermaleng.2019.02.119.

Tikadar A, Joshi Y, Kumar S (2022) Comparison between Direct Winding Heat Exchanger and Slot-liner Confined Evaporative Cooling of Electric Motor. In: InterSociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, ITHERM. IEEE Computer Society

Tikadar A, Kim JW, Joshi Y, Kumar S. Flow-assisted evaporative cooling for electric motor. IEEE Trans Transp Electrification. 2022;8:1128–43. https://doi.org/10.1109/TTE.2021.3107505.

Park J, An J, Han K, et al. Enhancement of cooling performance in traction motor of electric vehicle using direct slot cooling method. Appl Therm Eng. 2022. https://doi.org/10.1016/j.applthermaleng.2022.119082.

Le W, Lin M, Lin K, et al. A rotor cooling enhanced method for axial flux permanent magnet synchronous machine with housing-cooling. IEEE Trans Appl Supercond. 2021. https://doi.org/10.1109/TASC.2021.3103728.

Veg L, Laksar J (2019) Comparison of two types of cooling of axial flux permanent magnet machines by CFD simulation. In: International Conference on Electical Drives and Power Electronics. KoREMA, pp. 303–306

Peng Q, Cao J, Li D, An G (2021) Water cooling structure design and temperature field analysis of low floor direct drive permanent magnet synchronous motor. In: Proceedings of 2021 IEEE 4th International Electrical and Energy Conference, CIEEC 2021. Institute of Electrical and Electronics Engineers Inc.

Rehman Z, Seong K. Three-D numerical thermal analysis of electric motor with cooling jacket. Energies (Basel). 2018. https://doi.org/10.3390/en11010092.

Hu G, Wei Z, Chen X, Zhou Y (2021) The Thermal Analysis of Permanent Magnet Synchronous In-Wheel Motor Based on Thermal Network Method. In: 2021 4th International Conference on Energy, Electrical and Power Engineering, CEEPE 2021. Institute of Electrical and Electronics Engineers Inc., pp. 399–404

Wu S, Hao D, Tong W. Temperature field analysis of mine flameproof outer rotor permanent magnet synchronous motor with different cooling schemes. CES Trans Electric Mach Syst. 2022;6:162–9. https://doi.org/10.30941/cestems.2022.00022.

Lindh P, Petrov I, Immonen P, et al. Performance of a direct-liquid-cooled motor in an electric bus under different load cycles. IEEE Access. 2019;7:86897–905. https://doi.org/10.1109/ACCESS.2019.2925711.

Lim DH, Lee MY, Lee HS, Kim SC. Performance evaluation of an in-wheel motor cooling system in an electric vehicle/hybrid electric vehicle. Energies (Basel). 2014;7:961–71. https://doi.org/10.3390/en7020961.

Garud KS, Hwang SG, Han JW, Lee MY. Performance characteristics of the direct spray oil cooling system for a driving motor of an electric vehicle. Int J Heat Mass Transf. 2022. https://doi.org/10.1016/j.ijheatmasstransfer.2022.123228.

Ye L, Tao F, Qi L, Xuhui W (2016) Experimental investigation on heat transfer of directly-oil-cooled permanent magnet motor; Experimental investigation on heat transfer of directly-oil-cooled permanent magnet motor

Volpe G, Chong YC, Staton DA, Popescu M (2018) Thermal management of a racing e- machine. In: Proceedings-2018 23rd International Conference on Electrical Machines, ICEM 2018. Institute of Electrical and Electronics Engineers Inc., pp. 2689–2694

Kovacik M, Rafajdus P, Stano M (2022) Analysis of loss and thermal performance of high speed PMSM for automotive application. In: 14th International Conference ELEKTRO, ELEKTRO 2022-Proceedings. Institute of Electrical and Electronics Engineers Inc.

Thangaraju SK, Rajoo S, Munisamy KM (2021) Numerical analysis of oil cooled pmsm jacket with horizontal strips design. In: 2021 4th Asia Conference on Energy and Electrical Engineering, ACEEE 2021. Institute of Electrical and Electronics Engineers Inc., pp. 127–130

Lee KH, Cha HR, Kim YB. Development of an interior permanent magnet motor through rotor cooling for electric vehicles. Appl Therm Eng. 2016;95:348–56. https://doi.org/10.1016/j.applthermaleng.2015.11.022.

Wang H, Liu X, Kang M, et al. Oil injection cooling design for the IPMSM applied in electric vehicles. IEEE Trans Transp Electrification. 2022;8:3427–40. https://doi.org/10.1109/TTE.2022.3161064.

Nonneman J, Van Der Sijpe B, T’Jollyn I, et al (2021) Evaluation of high performance rotor cooling techniques for permanent magnet electric motors. In: 2021 IEEE International Electric Machines and Drives Conference, IEMDC 2021. Institute of Electrical and Electronics Engineers Inc.

Zhu G, Li L, Mei Y, et al. Design and analysis of a self-circulated oil cooling system enclosed in hollow shafts for axial-flux PMSMs. IEEE Trans Veh Technol. 2022;71:4879–88. https://doi.org/10.1109/TVT.2022.3154150.

Gai Y, Chong YC, Adam H, et al (2019) Power losses and thermal analysis of a hollow-shaft rotor cooling system. In: 22nd International Conference on Electrical Machines and Systems (ICEMS)

Nonneman J, Evans I, Vanhee S, et al (2022) Experimental investigation of a novel direct rotor cooling method for an interior permanent magnet synchronous machine. In: THERMINIC 2022-28th International Workshop on Thermal Investigations of ICs and Systems, Proceedings. Institute of Electrical and Electronics Engineers Inc.

Faghri A. Heat pipe science and technology. Taylor and Francis Group; 1995.

Guo Y, Wang A (2021) Thermal design and simulation of winding cooling for permanent magnet synchronous motor of electric vehicle. In: 2021 IEEE 4th Student Conference on Electric Machines and Systems, SCEMS 2021-Proceedings. Institute of Electrical and Electronics Engineers Inc.

Dong C, Qian Y, Zhang Y, et al. (2020) Coupled thermal-electromagnetic parametric modeling of permanent magnet machine based on flat heat pipe cooling. In: 23rd International Conference on Electrical Machines and Systems, ICEMS 2020. Institute of Electrical and Electronics Engineers Inc., pp. 1689–1694

Dong C, Hu X, Qian Y, et al. (2021) Thermal field analysis of electric propulsion drive motors with flat heat pipe cooling. In: ICEMS 2021-2021 24th International Conference on Electrical Machines and Systems. Institute of Electrical and Electronics Engineers Inc., pp. 495–500

Dong C, Hu X, Qian Y, et al. Thermal management integrated with flat heat pipes for in-slot stator windings of electric motors. IEEE Trans Ind Appl. 2022. https://doi.org/10.1109/TIA.2022.3204239.

Putra N, Ariantara B. Electric motor thermal management system using L-shaped flat heat pipes. Appl Therm Eng. 2017;126:1156–63. https://doi.org/10.1016/j.applthermaleng.2017.01.090.

Zhang X, Zhang C*, Fu P, et al. (2018) A novel cooling technique for the windings of high-torque-density permanent magnet machines. In: 2018 21st International Conference on Electrical Machines and Systems (ICEMS) Oct 7–10, 2018 Jeju, Korea

Aprianingsih N, Winarta A, Ariantara B, Putra N (2018) Thermal performance of pulsating heat pipe on electric motor as cooling application. In: E3S Web of Conferences. EDP Sciences

Zhang C, Zhang X, Zhao F, et al. Improvements on permanent magnet synchronous motor by integrating heat pipes into windings for solar unmanned aerial vehicle. Green Energy Intel Transp. 2022;1:100011. https://doi.org/10.1016/j.geits.2022.100011.

Wrobel R, Reay D. Heat pipe based thermal management of electrical machines–a feasibility study. Therm Sci Eng Prog. 2022. https://doi.org/10.1016/j.tsep.2022.101366.

Yu Z, Li Y, Jing Y, Wang J. Cooling system of outer rotor SPMSM for a two-seater all-electric aircraft based on heat pipe technology. IEEE Trans Transp Electrification. 2022;8:1656–64. https://doi.org/10.1109/TTE.2021.3127555.

Chai F, Cao Y, Pei Y (2022) Design and analysis of high torque density permanent magnet synchronous motor based on heat pipe. In: 2022 International Conference on Electrical Machines and Systems, ICEMS 2022. Institute of Electrical and Electronics Engineers Inc.

Zhao H, Zhang X, Li J, et al. Heat pipe bending effect on cooling effectiveness in electrical machines. IEEE Trans Energy Convers. 2023;38:2011–21. https://doi.org/10.1109/TEC.2023.3249971.

Geng R, Liu G, Mei T, et al (2023) Design of cooling system for high torque density permanent magnet synchronous motor based on heat pipe. In: IEEE Student Conference on Electric Machines and Systems (SCEMS). Institute of Electrical and Electronics Engineers

Zhao H, Zhang X, Li J, et al. Effectiveness of thermal interface materials on electrical machines thermal performance with heat pipes. IEEE Trans Transp Electrification. 2023. https://doi.org/10.1109/TTE.2023.3274554.

Wang JX, Li YZ, Wang SN, et al. Experimental investigation of the thermal control effects of phase change material based packaging strategy for on-board permanent magnet synchronous motors. Energy Convers Manag. 2016;123:232–42. https://doi.org/10.1016/j.enconman.2016.06.045.

Wang S, Li YZ, Liu Y, et al (2015) Temperature control of permanent-magnet synchronous motor using phase change material. In: IEEE/ASME International Conference on Advanced Intelligent Mechatronics, AIM. Institute of Electrical and Electronics Engineers Inc., pp. 1635–1640

Wang S, Li Y, Li YZ, et al. Transient cooling effect analyses for a permanent-magnet synchronous motor with phase-change-material packaging. Appl Therm Eng. 2016;109:251–60. https://doi.org/10.1016/j.applthermaleng.2016.08.036.

Bellettre J, Sartre V, Biaist F, Lallemand A. Transient state study of electric motor heating and phase change solid-liquid cooliNG. Appl Therm Eng. 1997;17:17–31.

Ayat S, Yon S, Serghine C, et al (2019) The use of phase change material for the cooling of electric machine windings formed with hollow conductors. IEEE

Wang S, Li Y, Li YZ, et al. Conception and experimental investigation of a hybrid temperature control method using phase change material for permanent magnet synchronous motors. Exp Therm Fluid Sci. 2017;81:9–20. https://doi.org/10.1016/j.expthermflusci.2016.10.005.

Liu X, Shi Y, Chu J, et al. A new phase-change cooling method for the frequent start-stop electric motor. Appl Therm Eng. 2021. https://doi.org/10.1016/j.applthermaleng.2021.117504.

Li B, Yuan Y, Gao P, et al. Cooling structure design for an outer-rotor permanent magnet motor based on phase change material. Therm Sci Eng Prog. 2022. https://doi.org/10.1016/j.tsep.2022.101406.

Yao Y, Gu L, Fan T, et al (2011) Evaluation of heat transfer characteristic of Aluminum Nitride (AlN) potting compound for the end windings of permanent magnet synchronous machines. In: 2011 International Conference on Electrical and Control Engineering, ICECE 2011-Proceedings. Pp. 4498–4501

Polikarpova M, Lindh PM, Tapia JA, Pyrhönen JJ (2014) Application of potting material for a 100 kW radial flux PMSM. In: Proceedings-2014 International Conference on Electrical Machines, ICEM 2014. Institute of Electrical and Electronics Engineers Inc., pp. 2146–2151

Polikarpova M, Lindh P, Gerada C, et al. Thermal effects of stator potting in an axial-flux permanent magnet synchronous generator. Appl Therm Eng. 2015;75:421–9. https://doi.org/10.1016/j.applthermaleng.2014.09.044.

Sun Y, Zhang S, Yuan W, et al. Applicability study of the potting material based thermal management strategy for permanent magnet synchronous motors. Appl Therm Eng. 2019;149:1370–8. https://doi.org/10.1016/j.applthermaleng.2018.12.141.

Sun Y, Zhang S, Chen G, et al. Experimental and numerical investigation on a novel heat pipe based cooling strategy for permanent magnet synchronous motors. Appl Therm Eng. 2020. https://doi.org/10.1016/j.applthermaleng.2020.114970.

Huang J, Shoai Naini S, Miller R, et al. A hybrid electric vehicle motor cooling system-design, model, and control. IEEE Trans Veh Technol. 2019;68:4467–78. https://doi.org/10.1109/TVT.2019.2902135.

Li Y, Li Q, Fan T, Wen X. Heat dissipation design of end winding of permanent magnet synchronous motor for electric vehicle. Energy Rep. 2023;9:282–8. https://doi.org/10.1016/j.egyr.2022.10.416.

Chen W, Ju Y, Yan D, et al. Design and optimization of dual-cycled cooling structure for fully-enclosed permanent magnet motor. Appl Therm Eng. 2019;152:338–49. https://doi.org/10.1016/j.applthermaleng.2019.02.070.

Zhang C-N, Guo F-L, Dong Y-G (2019) Oil-water composite cooling method of hub motor for electric vehicles

Chang M, Lai B, Wang H, et al. Comprehensive efficiency analysis of air-cooled vs water-cooled electric motor for unmanned aerial vehicle. Appl Therm Eng. 2023. https://doi.org/10.1016/j.applthermaleng.2023.120226.

Gammaidoni T, Zembi J, Battistoni M, et al. CFD analysis of an electric motor’s cooling system: model validation and solutions for optimization. Case Stud Therm Eng. 2023. https://doi.org/10.1016/j.csite.2023.103349.

He L, Feng Y, Zhang Y, Tong B. Methods for temperature estimation and monitoring of permanent magnet: a technology review and future trends. J Braz Soc Mech Sci Eng. 2024;46:174. https://doi.org/10.1007/s40430-024-04723-2.

Tariq SL, Ali HM, Akram MA, et al. Nanoparticles enhanced phase change materials (NePCMs)-A recent review. Appl Therm Eng. 2020;176:115305.

Author information

Authors and Affiliations

Contributions

A.G.S. helped in idea for the article, literature search, and data analysis, V.P.T. was involved in literature search and draft review, A.S.D helped in critical revision of the work.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shewalkar, A.G., Dhoble, A.S. & Thawkar, V.P. Review on cooling techniques and analysis methods of an electric vehicle motor. J Therm Anal Calorim (2024). https://doi.org/10.1007/s10973-024-13091-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10973-024-13091-x