Abstract

Due to the serious environmental impacts of plastic pollution, some conventional plastics have been replaced with biodegradable alternatives. However, these biodegradable options can also fragment and form microplastics, which can be ingested by and harm various biota. The standard methods for quantifying ingested microplastics involve digestion of the gut or the whole organism using acidic, alkaline, or oxidative processes. However, these aggressive methods may destroy biodegradable microplastics, leading to erroneous results. Therefore, in this study, we employed thermal analysis methods, specifically differential scanning calorimetry (DSC) and thermogravimetry (TG), to quantify the ingestion of poly-3-hydroxybutyrate (P3HB), a biodegradable microplastic, by the freshwater crustacean, Daphnia magna. During chronic experiments, we analysed organisms exposed to P3HB with sizes smaller than 125 and 63 μm, at concentrations ranging from 1.56–25 mg L−1. DSC identified an endothermic peak associated with the melting of semicrystalline P3HB, and its enthalpies were utilised to compute the number/mass of P3HB ingested by D. magna. Notably, shifts in melting points suggested that higher concentrations induced particle agglomeration, and these agglomerates could not penetrate deeply into the organism. The TG approach involved subtracting the mass loss between 200 and 400 °C in D. magna specimens exposed to P3HB suspensions from controls without P3HB exposure. Both methods provided comparable data, revealing that, depending on particle size, individual D. magna ingested up to 10% of their body mass. Our findings indicate that both methods effectively detect P3HB (and potentially other plastic fragments), with DSC demonstrating better sensitivity. While the suggested approach did not enable us to calculate the level of determination or quantification, we were able to demonstrate that DSC can detect P3HB in only one specimen of D. magna exposed to the lowest suspension concentration. This indicates that D. magna exposed to the 63 μm fraction ingested approximately 3 μg of P3HB, whereas those exposed to the 125 μm P3HB ingested around 4 μg of P3HB. The introduced methods expand the possibilities for detecting ingested microplastics and probably also nanoplastics, in zooplankton and possibly also other species.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Introduction

Plastic pollution is among the most frequently discussed environmental issues. Approximately 10% of the plastics currently produced enter the oceans [1], with an exponential increase expected in the coming years [2]. Plastic particles, namely macroplastics, are easily visible and adversely affect wildlife organisms through entanglement, ingestion, and lacerations [3]. Microplastics (MPs), plastic particles of between 1 and 1,000 μm [4], can be taken up by a number of organisms due to their size. Recently, the term “nanoplastics” has also been introduced to describe plastic debris measuring less than 100 nm in size. The ingestion, primarily of microplastics, and to a lesser extent, nanoplastics, as well as their adverse effects have been demonstrated in freshwater and marine organisms across the food chain [1, 2, 5,6,7].

As the issue of plastic waste and environmental pollution from traditional plastics intensifies, there is a rising demand for eco-friendly and degradable materials. Biodegradable polymers (BDPs) are increasingly in the spotlight due to their ability to biodegrade, offering a solution to the challenge of enduring plastics. Under aerobic conditions, BDPs break down into carbon dioxide, water, and biomass, while methane is produced under anaerobic conditions. They are used across various sectors, including medicine, textiles, personal care manufacturing, agriculture, and packaging, as alternatives to traditional plastics [8,9,10]. However, similar to their conventional counterparts, BDPs can break down into small particles in natural settings, leading to the accumulation of significant quantities of so-called microbioplastics (i.e., biodegradable microplastics [9, 11]. It should be noted that we use the term “microplastics” for both biodegradable and non-biodegradable plastic particles in this work. These microplastics can persist for extended periods despite their biodegradable nature. Biodegradation is a lengthy process influenced by biotic and abiotic environmental factors, such as temperature, humidity, pH, oxygen level, active biological substances, and enzymes. Depending on the specific polymer, BDPs can remain in the natural environment for several years or even decades [12, 13].

Consequently, microplastics from both biodegradable and non-biodegradable plastics can be ingested by various organisms, as previously documented. For example, Cole et al. [1] found that 13 zooplankton taxa could ingest polystyrene (PS) beads ranging from 1.7 to 30.6 μm in size. The uptake rate varied based on the taxon, life stage, bead size, and the appendages of the exposed zooplankton. Scherer et al. [14] further confirmed the ingestion of microplastics by freshwater invertebrates, using species like Daphnia magna, Chironomus riparius, Physella acuta, Gammarus pulex, and Lumbriculus variegatus; all ingested PS microspheres of between 1 and 10 μm. However, the probability is that ingestion is influenced by several factors: the type of microplastics, their concentration, and the frequency with which these particles fall within the size range of naturally consumable items for the organism [15]. The methods used for the quantification of microplastics include fluorescence labelling of microplastics combined with spectrophotometric techniques [1, 16, 17], stereo/microscopic examinations [15, 18,19,20,21,22,23,24,25,26,27], and determining particle volume concentration through particle size analysers [28], gravimetric methods [27], gut content inspection [22, 29] or pyrolysis–gas chromatography-mass spectrometry [30]. However, many of these methods can have critical limitations; for example, Schür et al. [24] caution that fluorescent labelling might result in dye leaching within the organisms, potentially leading to false positives in microplastic detection. In addition, some particles can be overlooked during a visual inspection, and digestion methods can lead to a potential loss of certain microplastics when recovering them from the gut or the whole organism. For example, a digestion of fragile Bakelite microplastics led to a 20% loss of the particles’ mass [31]. This can also be true for biodegradable microplastics that are supposedly less persistent.

In this context, we aimed to develop an approach for directly quantifying microplastics in small aquatic organisms. For this purpose, the water flea, D. magna, was selected as a model filter-feeding zooplankton. This organism non-selectively consumes particles ranging in size from < 1 μm to around 70 μm [15] and is a widely used model organism in microplastic research [32, 33]. Poly-3-hydroxybutyrate (P3HB) was chosen as the model microplastic particle due to the recent interest in the use of this polymer in various applications [34, 35] meaning there is the possibility that high amounts of it will enter the aquatic environment. We focused on using two fundamental thermoanalytical methods: differential scanning calorimetry (DSC) and thermogravimetry (TG). Both methods are robust, sensitive, and commonly used for qualitative and quantitative analysis of samples and can be used with any special sample pretreatment.

The objectives of this study are:

-

(i)

To develop an approach for both qualitative and quantitative analysis of P3HB particles ingested by D. magna;

-

(ii)

To investigate the influence of particle size on the quantity of P3HB ingested by D. magna;

-

(iii)

To compare the reliability of the employed methods.

Experimental

Microplastics

Spherical-shaped P3HB (ENMAT Y3000) microplastics were used (TianAn Biologic Materials Co., Ltd., Ningbo City, China). A suspension of P3HB microplastics in Milli-Q water was sieved on 63- and 125 μm mesh stainless-steel sieves, and both size fractions (< 63 μm–referred to as ‘63’ and from 63 to 125 μm–referred to as ‘125’) were subsequently dried in glass beakers in a fume hood at room temperature. Importantly, as follows from the distribution provided in Figs. S1 and S2, the particle size does not correspond precisely to those sizes because the particles were not ultrasonicated, as described further on. However, we used the particle preparation mesh size for a more straightforward transposition to the text.

Exposure of Daphnia magna to microplastics

The test organism D. magna–obtained from a laboratory culture at the Institute of Chemistry and Technology of Environmental Protection (Faculty of Chemistry, Brno University of Technology, Czech Republic)—was cultured in ASTM-reconstituted hard water [36] modified with selenium, vitamins (biotin, thiamine, and cyanocobalamin, according to the OECD guideline 211 [37]) and 20 µL L−1 of seaweed extract (Marinure, Glenside, Scotland) according to [38]. The medium was changed three times a week, and the organisms were fed with the green algae, Desmodesmus subspicatus, equivalent to 200 µg carbon per organism daily. The culture was kept at a temperature of 20 ± 1 °C and a 16:8 (800–1,000 lx) light:dark regime.

Following the preliminary experiment our and other groups [18], the concentration range of P3HB particles in suspensions was selected as 0, 1.56, 3.125, 6.25, 12.5, and 25 mg L−1. The particle suspensions were prepared by weighing the desired amount of P3HB and transferring it to a volumetric flask. Following this, the volumetric flask was filled to the mark with ASTM-reconstituted hard water enriched with vitamins and seaweed extract (see above). The as-prepared suspension was ultrasonicated for 10 min to disperse the particles. The experiments were conducted in 150 mL glass beakers, and each was filled with 100 mL of test suspension. Each experiment (63 and 125 μm) involved ten replicates of the same exposure concentrations and was repeated three times. One D. magna juvenile younger than 24 h was placed into each test vessel. The experimental conditions were identical to the culture conditions. At the end of the test, living D. magna organisms were carefully rinsed with deionised water to ensure that P3HB particles did not remain on their surfaces. They were subsequently air-dried.

Analysis of poly-3-hydroxybutyrate content in Daphnia magna

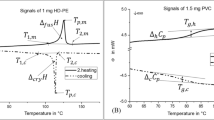

The melting enthalpy of P3HB in air-dried D. magna analysis was conducted using DSC (TA Instruments Q250 [New Castle, DE, USA]). Six or seven D. magna specimens were placed into an aluminium Tzero pan, non-hermetically sealed to ensure that the D. magna was in contact with the bottom of the pan. The following temperature programme was utilised: (1) heating from 30 °C to 105 °C using a heating rate of 10 °C min−1; (2) an isotherm at 105 °C for one minute (to assure to remove the residual water content); (3) heating from 105°C to 200 °C using a heating rate of 10 °C min−1. The same method was used for P3HB measurement. Samples were measured in triplicate with some exceptions. Since P3HB melts at around 170 °C, the heating phase “3” was used to analyse P3HB content in D. magna. Here, an endothermal peak corresponding to P3HB melting appeared in the D. magna exposed to P3HB suspension. The peak was analysed in terms of its area (melting enthalpy) and onset temperature.

Samples analysed using DSC were then collected, removed from the pan, and measured using TG (TA Instruments Q550 [New Castle, DE, USA]). This approach could be used as the D. magna species were not degraded (maximal temperature used in DSC experiment was only 200 °C), the sample was only pre-dried, which did not affect the TG experiment. Heating from laboratory temperature (25 °C) up to 700 °C at 10 °C min−1 was used to analyse the moisture content (up to 200 °C) and mass loss (200–400 °C). The D. magna exposed to the P3HB suspension and the control without P3HB were analysed. Previously obtained TG analysis of pure P3HB samples determined that P3HB degrades at 200–400 °C. Therefore, in this temperature interval, the determination of P3HB content in D. magna was subtracted from the mass loss of D. magna with and without P3HB.

The DSC determination of the P3HB content was analysed as follows: 1 g of purely crystalline P3HB would give the enthalpy 146 J [39, 40], the measured enthalpy divided by 146 and multiplied by 1 g would give the content (in grams) of the crystalline part ingested by D. magna. One of the measurements included six pieces of D. magna treated with 125 µg P3HB at 25 mg L−1; it yielded a melting peak with 0.0138 J. Calculation of (0.0138/146) × 1 = 9.5 × 10−5 g (9.5 × 10−2 mg) of P3HB with 100% crystallinity. However, the crystallinity of P3HB used in this work was not 100%; instead, for pure P3HB, DSC experiments showed a single peak with an onset temperature of (164.5 ± 0.2) °C and a melting enthalpy of (71.2 ± 0.6) J g−1. Accordingly, the crystallinity of P3HB used in this work was approximately 49%, i.e. (71.2/146) × 100 = 48.7%. Therefore, considering the amorphous portion of P3HB, the recalculation yields 0.19 mg of P3HB in a measured sample of D. magna. This content was then used for the determination of the content of P3HB in D. magna.

Results

Differential scanning calorimetry analysis

As discussed in the materials and methods section, the melting enthalpy of P3HB is proportional to its content in the sample of D. magna exposed to P3HB suspension. Figure 1 shows exemplary records of D. magna exposed to 1.56 and 25 mg L−1 P3HB suspension, fraction 125, and control treatment with no P3HB. The melting event appeared at temperatures around 170 °C and was highly noticeable even in samples exposed to the lowest concentrations of P3HB. In addition, the peak area corresponding to the content of P3HB increased with a higher initial concentration of P3HB in suspension. Conversely, no melting event occurred in the D. magna from the control treatment group (no P3HB).

The amounts of P3HB in D. magna exposed to various concentrations are reported in Fig. 2. The results confirm the preliminary observation (Fig. 1) that as the initial concentration of P3HB in suspension increases, so does the content of P3HB in D. magna. Notably, in the D. magna exposed to 125 μm P3HB, the amount detected via DSC ranged from 0.5 to 6.3 mass%; it ranged from 0.5 to 10.3 mass% in D. magna exposed to 63 μm.

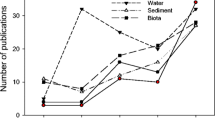

Thermogravimetry analysis

The TG experiments compared the TG record (i.e. mass losses) of D. magna exposed to P3HB microplastics with those from the control treatment. For better clarity, Fig. 3 displays the derivative TG records (DTG). Water evaporation mainly takes place up to approximately 200 °C. Degradation starts above 200 °C and proceeds to approximately 650 °C. The comparison of the DTG record of D. magna with and without P3HB indicated that the differences on the DTG curves were noticeable in the range of 200–400 °C. Differences in mass losses in the 200–400 °C range were therefore used to determine the P3HB content of D. magna.

The TG results (Fig. 4) showed the same trend as the DSC results (Fig. 2), i.e. an increased content of P3HB in D. magna exposed to higher concentrations of P3HB in suspension. As shown in Fig. 5, which compares the DSC and TG results, the results were comparable in the concentration range of 3.125–25 mg L−1, whereas at 1.56 mg L−1, the results differed substantially.

The last parameter determined from the DSC data was the onset temperature of melting P3HB in D. magna. The results were compared with the pure P3HB results. These are summarised in Fig. 6 and show that the most considerable differences were observed in the D. magna exposed to lower concentrated suspensions (1.56 and 3.125 mg L−1). In contrast, the higher concentrations showed no difference compared with pure P3HB.

Discussion

Quantitative and qualitative analysis of microplastics ingested by zooplankton is challenging due to the small size of the organisms studied and the associated low concentrations of ingested microplastics. Many of the methods used to date have numerous limitations and are time-consuming, with the loss of particles during analysis a common problem. We tested DSC and TG methods for rapid qualitative and quantitative analysis of microplastics to overcome these problems. It was demonstrated that using DSC and TG methods is feasible, and that they can reliably detect the microplastic P3HB in the water flea, D. magna.

The DSC method has been used to determine microplastics in various environmental matrices, mainly in water (after sample preconcentration and drying [41,42,43,44,45,46,47]). Nevertheless, these approaches were never designed to directly analyse the ingested MPs in zooplankton without pretreatment. In this study, we evaluated the mass of ingested P3HB (Fig. 2), and the results showed that approximately 4–22 and 3–34 μg of P3HB for 125 and 63 μm fractions, respectively, were ingested by one D. magna. An average air-dried D. magna mass was around 426 μg, including approximately 10% moisture.

The approach reported here did not allow for calculating the level of determination or level of quantification for both methods. To test the methods’ sensitivity, an additional DSC experiment with only one piece of D. magna exposed to the lowest concentration (1.56 mg L−1) of P3HB gave 3 μg of P3HB per one D. magna for the 63 μm fraction and 4 μg for 125 μm. This showed that DSC is sensitive enough to determine the presence of P3HB in one D. magna specimen. Quantitatively, the result obtained for one D. magna at both particle sizes corresponds to the data obtained for measurements with a larger amount of D. magna (explained above), confirming that DSC can be reliably used for different masses of investigated organisms.

Furthermore, higher concentrations of P3HB showed minimal differences in melting temperatures compared with pure P3HB, whereas at lower concentrations, the temperatures were around 3 °C higher. We speculate that this may be due to the distribution of particles in the guts of D. magna. When the concentration is lower, the particles are deposited deeper inside D. magna, which thermally insulates the particle, causing a ‘delay’ (i.e. a higher melting point). In contrast, higher concentrations induce aggregation; larger aggregates are less isolated by the body of D. magna and are not located as deeply in its body. As a result, there is no (or a more minor) difference compared with pure P3HB. We observed the aggregation from a concentration of 6.25 mg L−1 of P3HB in suspension in both size fractions. Since there was a difference in the amount of P3HB in D. magna between the individual fractions, it can be assumed that aggregation occurred in the D. magna itself after it was ingested.

Nevertheless, the DSC method also has some limitations, with one of the most important being the melting point of microplastics. Since P3HB has a relatively low melting point, temperatures above 200 °C would lead to the thermal degradation of D. magna (see TG record in Fig. 3). It is known that the degradation products could cause problems in the DSC cell such as cell walls contamination, sensors corrosion and others leading to baseline problems or even to DSC damage. In other words, the DSC method applies to the analysis of microplastics such as high-density polyethylene (melting temperature of 125 °C [48], low-density polyethylene (106–112 °C [49]), polylactic acid (150–160 °C [50]), and polypropylene (130–171 °C [51, 52]); it is less suitable for polyvinylchloride (115–245 °C [53]) and is unsuitable for polyethylene terephthalate (245–265 °C [54]) and polystyrene (207–297 °C [55]).

Thermal analysis methods are used to determine microplastics in various environmental compartments, mostly as pyrolysis techniques associated with gas analysis [56, 57]. However, there are also works that use gravimetric determination. For example, in [27], the authors exposed 100 pieces of D. magna of similar size to PS microplastics and compared their total mass with 100 pieces of D. magna that were not exposed to microplastics. However, this approach is problematic because D. magna’s mass is variable. For example, in the study cited, their mass ranged from 160 to 660 μg, which can strongly compromise the gravimetric approach. The use of TG eliminates this problem by using only parts of the mass loss of D. magna (i.e. it considers the percentage loss in individuals and not their total mass).

Both the DSC (Fig. 2) and the TG (Fig. 4) showed that the increase in P3HB in D. magna was nonlinear, reaching a maximum between 12.5 and 25 mg·L−1 in the 125 μm series, whereas the 63 μm fraction was still sharply increasing. As mentioned, D. magna can ingest particles smaller than 70 μm [15]. According to particle size distribution (Figs. S1 and S2), almost all of the particles could be ingested by D. magna; the fact that the group treated with the highest concentration of 125 μm P3HB particles did not ingest them to the same extent as those sized 63 μm is most likely due to the agglomeration of the particles, as mentioned above.

Furthermore, the results of both methods were comparable (Fig. 5), showing that they differ only in low concentrations. The position of the 1:1 line suggests the TG data deviation, the slope was 1.28, which value was mostly influenced by the deviation at lowest P3HB suspension content. This may be because we subtracted two TG curves from each other in this case, which can introduce an error to the P3HB quantitative determination. However, it should be noted that even the use of DSC could be problematic in the case of unknown microplastics, given that the crystallinity of P3HB is not always known. In our work, we obtained a 49% crystallinity. However, the literature data also reports values of 50–80% [58,59,60], which would slightly lower the P3HB content. Nevertheless, different crystallinity is not a problem if we conduct ecotoxicological or mesocosm experiments/studies where the material/microplastic properties can be determined/controlled and analysed.

Conclusions

In this work, we introduced two fast thermoanalytical approaches providing proxy data for determining microplastics ingested by zooplankton. Both methods are rapid and robust and do not require sample visualisation, chemicals (e.g. digestion), or physical sample pretreatment (e.g. grinding). The data provides information on the microplastic mass per mass of an animal/organism. Therefore, they cannot offer particle count data, as, for example, microscopy could. Nevertheless, the DSC method appeared able to analyse microplastics at low concentrations in a single D. magna. Although we examined only one type of microplastic, it can be assumed that DSC could be used for more polymer types, providing that their melting temperatures are appropriate for analysing individual peaks. In addition, using DSC on zooplankton obtained from experiments conducted under controlled conditions with known microplastic crystallinity would make it possible to obtain more precise data,

References

Cole M, Lindeque P, Fileman E, Halsband C, Goodhead R, Moger J, et al. Microplastic ingestion by zooplankton. Environ Sci Technol. 2013;47:6646–55.

Samadi A, Kim Y, Lee SA, Kim YJ, Esterhuizen M. Review on the ecotoxicological impacts of plastic pollution on the freshwater invertebrate Daphnia. Environ Toxicol. 2022;37:2615–38.

Kühn S, Bravo Rebolledo EL, van Franeker JA. Deleterious effects of litter on marine life. Marine anthropogenic litter. Cham: Springer; 2015. p. 75–116.

Hartmann NB, Hüffer T, Thompson RC, Hassellöv M, Verschoor A, Daugaard AE, et al. Are we speaking the same language? Recommendations for a definition and categorization framework for plastic Debris. Environ Sci Technol. 2019;53:1039–47.

Lusher AL, Welden NA, Sobral P, Cole M. Sampling, isolating and identifying microplastics ingested by fish and invertebrates. Analytical Methods. London: Royal Society of Chemistry; 2017. p. 1346–60.

Rakib MRJ, Sarker A, Ram K, Uddin MG, Walker TR, Chowdhury T, et al. Microplastic toxicity in aquatic organisms and aquatic ecosystems: a review. Water Air Soil Pollut. 2023;234:1–28.

de Sá LC, Oliveira M, Ribeiro F, Rocha TL, Futter MN. Studies of the effects of microplastics on aquatic organisms: what do we know and where should we focus our efforts in the future? Sci Total Environ. 2018;645:1029–39.

Luckachan GE, Pillai CKS. Biodegradable polymers-a review on recent trends and emerging perspectives. J Polym Environ. 2011;19:637–76.

Song JH, Murphy RJ, Narayan R, Davies GBH. Biodegradable and compostable alternatives to conventional plastics. Philos Trans Royal Soc B Biol Sci. 2009;364:2127–39.

Zhao X, Cornish K, Vodovotz Y. Narrowing the gap for bioplastic use in food packaging: an update. Environ Sci Technol. 2020;54:4712–32.

Fojt J, David J, Přikryl R, Řezáčová V, Kučerík J. A critical review of the overlooked challenge of determining micro-bioplastics in soil. Sci Total Environ. 2020;745: 140975.

Agarwal S. Biodegradable polymers: present opportunities and challenges in providing a microplastic-free environment. Macromol Chem Phys. 2020;221:2000017.

Wei X-F, Bohlén M, Lindblad C, Hedenqvist M, Hakonen A. Microplastics generated from a biodegradable plastic in freshwater and seawater. Water Res. 2021;198: 117123.

Scherer C, Brennholt N, Reifferscheid G, Wagner M. Feeding type and development drive the ingestion of microplastics by freshwater invertebrates. Sci Rep. 2017;7:17006.

Frydkjær CK, Iversen N, Roslev P. Ingestion and egestion of microplastics by the cladoceran daphnia magna: effects of regular and irregular shaped plastic and sorbed phenanthrene. Bull Environ Contam Toxicol. 2017;99:655–61.

Rist S, Baun A, Hartmann NB. Ingestion of micro- and nanoplastics in Daphnia magna—Quantification of body burdens and assessment of feeding rates and reproduction. Environ Pollut. 2017;228:398–407.

Sadler DE, Brunner FS, Plaistow SJ. Temperature and clone-dependent effects of microplastics on immunity and life history in Daphnia magna. Environ Pollut. 2019;255: 113178.

Kokalj AJ, Kunej U, Skalar T. Screening study of four environmentally relevant microplastic pollutants: uptake and effects on Daphnia magna and Artemia franciscana. Chemosphere. 2018;208:522–9.

Canniff PM, Hoang TC. Microplastic ingestion by Daphnia magna and its enhancement on algal growth. Sci Total Environ. 2018;633:500–7.

De Felice B, Sabatini V, Antenucci S, Gattoni G, Santo N, Bacchetta R, et al. Polystyrene microplastics ingestion induced behavioral effects to the cladoceran Daphnia magna. Chemosphere. 2019;231:423–31.

Kim D, Kim H, An Y-J. Effects of synthetic and natural microfibers on Daphnia magna–Are they dependent on microfiber type? Aquat Toxicol. 2021;240: 105968.

Jemec A, Horvat P, Kunej U, Bele M, Kržan A. Uptake and effects of microplastic textile fibers on freshwater crustacean Daphnia magna. Environ Pollut. 2016;219:201–9.

Elizalde-Velázquez A, Carcano AM, Crago J, Green MJ, Shah SA, Cañas-Carrell JE. Translocation, trophic transfer, accumulation and depuration of polystyrene microplastics in Daphnia magna and Pimephales promelas. Environ Pollut. 2020;259:113937.

Schür C, Rist S, Baun A, Mayer P, Hartmann NB, Wagner M. When fluorescence is not a particle: the tissue translocation of microplastics in Daphnia magna Seems an Artifact. Environ Toxicol Chem. 2019;38:1495–503.

Hoffschröer N, Grassl N, Steinmetz A, Sziegoleit L, Koch M, Zeis B. Microplastic burden in Daphnia is aggravated by elevated temperatures. Zoology. 2021;144: 125881.

Castro GB, Bernegossi AC, Felipe MC, Corbi JJ. Is the development of Daphnia magna neonates affected by short-term exposure to polyethylene microplastics? J Environ Sci Health Part A. 2020;55:935–46.

Lin H, Yuan Y, Jiang X, Zou J-P, Xia X, Luo S. Bioavailability quantification and uptake mechanisms of pyrene associated with different-sized microplastics to Daphnia magna. Sci Total Environ. 2021;797: 149201.

Colomer J, Müller MF, Barcelona A, Serra T. Mediated food and hydrodynamics on the ingestion of microplastics by Daphnia magna. Environ Pollut. 2019;251:434–41.

Wang M, Wang W-X. Selective ingestion and response by Daphnia magna to environmental challenges of microplastics. J Hazard Mater. 2023;458: 131864.

Nakano R, Gürses RK, Tanaka Y, Ishida Y, Kimoto T, Kitagawa S, et al. Pyrolysis-GC–MS analysis of ingested polystyrene microsphere content in individual Daphnia magna. Sci Total Environ. 2022;817: 152981.

Klun B, Rozman U, Ogrizek M, Kalčíková G. The first plastic produced, but the latest studied in microplastics research: the assessment of leaching, ecotoxicity and bioadhesion of Bakelite microplastics. Environ Pollut. 2022;307: 119454.

Pikuda O, Roubeau Dumont E, Chen Q, Macairan J-R, Robinson SA, Berk D, et al. Toxicity of microplastics and nanoplastics to Daphnia magna: current status, knowledge gaps and future directions. TrAC Trends Anal Chem. 2023;167: 117208.

Reilly K, Ellis LJA, Davoudi HH, Supian S, Maia MT, Silva GH, et al. Daphnia as a model organism to probe biological responses to nanomaterials—From individual to population effects via adverse outcome pathways. Front Toxicol. 2023;5:1178482.

Volova T, Prudnikova S, Boyandin A, Zhila N, Kiselev E, Shumilova A, et al. Constructing slow-release fungicide formulations based on poly(3-hydroxybutyrate) and natural materials as a degradable matrix. J Agric Food Chem. 2019;67:9220–31.

Volova TG, Prudnikova SV, Boyandin AN. Biodegradable poly-3-hydroxybutyrate as a fertiliser carrier. J Sci Food Agric. 2016;96:4183–93.

ASTM. E729–96 Standard guide for conducting acute toxicity tests on test materials with fishes, macroinvertebrates, and amphibians 2007

OECD. Test No. 211: Daphnia magna reproduction test. 2012.

Rosenfeldt RR, Seitz F, Schulz R, Bundschuh M. Heavy metal uptake and toxicity in the presence of titanium dioxide nanoparticles: a factorial approach using Daphnia magna. Environ Sci Technol. 2014;48:6965–72.

Luo R, Xu K, Chen GQ. Study of miscibility, crystallization, mechanical properties, and thermal stability of blends of poly(3-hydroxybutyrate) and poly(3-hydroxybutyrate-co-4- hydroxybutyrate). J Appl Polym Sci. 2007;105:3402–8.

Erceg M, Kovačić T, Klarić I. Thermal degradation of poly(3-hydroxybutyrate) plasticized with acetyl tributyl citrate. Polym Degrad Stab. 2005;90:313–8.

Shabaka SH, Ghobashy M, Marey RS. Identification of marine microplastics in Eastern Harbor, Mediterranean Coast of Egypt, using differential scanning calorimetry. Mar Pollut Bull. 2019;142:494–503.

Kühn S, van Oyen A, Booth AM, Meijboom A, van Franeker JA. Marine microplastic: preparation of relevant test materials for laboratory assessment of ecosystem impacts. Chemosphere. 2018;213:103–13.

Rodríguez Chialanza M, Sierra I, Pérez Parada A, Fornaro L. Identification and quantitation of semi-crystalline microplastics using image analysis and differential scanning calorimetry. Environ Sci Pollut Res. 2018;25:16767–75.

Bitter H, Lackner S. First quantification of semi-crystalline microplastics in industrial wastewaters. Chemosphere. 2020;258: 127388.

Majewsky M, Bitter H, Eiche E, Horn H. Determination of microplastic polyethylene (PE) and polypropylene (PP) in environmental samples using thermal analysis (TGA-DSC). Sci Total Environ. 2016;568:507–11.

Ivleva NP. Chemical analysis of microplastics and nanoplastics: challenges, advanced methods, and perspectives. Chem Rev. 2021;121:11886–936.

Bitter H, Lackner S. Fast and easy quantification of semi-crystalline microplastics in exemplary environmental matrices by differential scanning calorimetry (DSC). Chem Eng J. 2021;423: 129941.

Wei H, Thompson RB, Park CB, Chen P. Surface tension of high density polyethylene (HDPE) in supercritical nitrogen: effect of polymer crystallization. Colloids Surf A Physicochem Eng Asp. 2010;354:347–52.

Prasad A. A quantitative analysis of low density polyethylene and linear low density polyethylene blends by differential scanning calorimetery and fourier transform infrared spectroscopy methods. Polym Eng Sci. 1998;38:1716–28.

Sreekumar K, Bindhu B, Veluraja K. Perspectives of polylactic acid from structure to applications. Polym Renew Resour. 2021;12:60–74.

Liu L, Ilyushechkin A, Liang D, Cousins A, Tian W, Chen C, et al. Metal hydride composite structures for improved heat transfer and stability for hydrogen storage and compression applications. Inorg (Basel). 2023;11:181.

Zarbali A, Pinke B, Menyhárd A. Robustness study of a tensile modulus prediction model for semicrystalline polymers. Periodica Polytech, Chem Eng. 2023;67:232–41.

Summers JW. The melting temperature (or not melting) of poly(vinyl chloride). J Vinyl Add Tech. 2008;14:105–9.

Selke SE, Hernandez RJ. Packaging: polymers for containers. Encyclopedia of materials: science and technology. Amsterdam: Elsevier; 2001. p. 6646–52.

Wang N, Tu R, Ma X, Xie Q, Jiang X. Melting behavior of typical thermoplastic materials–An experimental and chemical kinetics study. J Hazard Mater. 2013;262:9–15.

Bouzid N, Anquetil C, Dris R, Gasperi J, Tassin B, Derenne S. Quantification of microplastics by pyrolysis coupled with gas chromatography and mass spectrometry in sediments: challenges and implications. Microplastics. 2022;1:229–39.

Woo H, Seo K, Choi Y, Kim J, Tanaka M, Lee K, et al. Methods of analyzing microsized plastics in the environment. Appl Sci. 2021;11:10640.

Melčová V, Svoradová K, Menčík P, Kontárová S, Rampichová M, Hedvičáková V, et al. FDM 3D Printed composites for bone tissue engineering based on plasticized Poly(3-hydroxybutyrate)/poly(d, l-lactide) blends. Polym (Basel). 2020;12:2806.

Pospisilova A, Vodicka J, Trudicova M, Juglova Z, Smilek J, Mencik P, et al. Effects of differing monomer compositions on properties of P(3HB-co-4HB) synthesized by Aneurinibacillus sp. H1 for various applications. Polym (Basel). 2022;14:2007.

dos Santos AJ, Oliveira Dalla Valentina LV, Hidalgo Schulz AA, Tomaz Duarte MA. From obtaining to degradation of PHB: material properties. Part I Ing Cienc. 2017;13:269–98.

Acknowledgements

This work was supported by the Ministry of Education, Youth and Sports of the Czech Republic [project FCH-S-23-8297]. GK acknowledge Slovenian Research and Innovation Agency [Research program P2-0191] for financial support. This article is based upon work from COST Action CA20101 Plastics monitoRIng detectiOn RemedIaTion recoverY—PRIORITY, supported by COST (European Cooperation in Science and Technology, www.cost.eu).

Funding

Open access publishing supported by the National Technical Library in Prague.

Author information

Authors and Affiliations

Contributions

PP contributed to conceptualization, investigation, writing—original draft; GK and EM helped in review and editing; HZG helped in writing—review & editing and conceptualization; JK contributed to conceptualization, methodology, data curation, writing—original draft, funding acquisition, visualisation, resources, and supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Procházková, P., Kalčíková, G., Maršálková, E. et al. Innovative approach for quantitative determination of ingested microplastics by Daphnia magna: use of differential scanning calorimetry and thermogravimetry. J Therm Anal Calorim (2024). https://doi.org/10.1007/s10973-024-12985-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10973-024-12985-0