Abstract

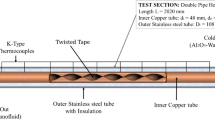

Passive inserts, notably twisted turbulator inserts (TTI) and perforated twisted turbulator inserts (PTTI) loaded with water-based ternary hybrid nanofluid (THNF), are employed in plain tube heat exchangers to enhance thermal performance. The investigation focuses on how THNF replacement inserts will impact energy utilization, exergy consumption, and the environment in the decades to come. Nanoparticles of copper oxide (CuO), aluminum oxide (Al2O3), and titanium oxide (TiO2) are dissolved in water, which functions as the working fluid, and the resulting THNF is injected at three distinct concentrations (0.06, 0.09, and 0.12%). Certain aspects of the flow of a control fluid are investigated in terms of energy, exergy, and emissions.

The experimental findings demonstrate that utilizing TTI and PTTI in conjunction with THNF substantially enhances the compact air heat exchanger's thermal and hydraulic efficiency. Heat transfer, friction factor, exergy change, and reversibility are greatly improved when turbulator inserts with PTTI and TTI are employed in plain tubes containing 0.12% (v/v) THNF. The CO2 discharge rises by 2.6–2.1 when PTTI or TTI turbulator inserts are inserted in the tube's core. Using PTTI with a concentration of 0.12% (v/v) THNF as the working fluid and a tube insert will provide PEC values in the range of 1.075–1.04. The thorough examination of heat transfer enhancement, friction factor, exergy efficiency, and environmental effect suggests that PTTI is a better passive device insert for heat transfer efficiency, particularly when combined with 0.12% (v/v) THNF.

Similar content being viewed by others

Abbreviations

- Aradiator :

-

Frontal area of HX

- Afin :

-

Peripheral area of the fin

- \(\mathop m\limits^{ \bullet }\) :

-

Mass flow rate, kg s−1

- \(\dot{Q}\) :

-

Heat transfer, W

- Al2O3 :

-

Aluminum oxides

- Cp :

-

Specific heat capacity, J kg−1 K−1

- CuO:

-

Copper oxide

- \(Dis_{{\text{CO}_{2} }}\) :

-

CO2 discharge

- Dh :

-

Hydraulic diameter, mm

- ff:

-

Friction factor

- \(f_{{\text{CO}_{2} }}\) :

-

Carbon discharge factor

- hf :

-

Heat transfer coefficient of fluid, W m−2.K−1

- Nu:

-

Nusselt number

- Δp:

-

Pressure drop, Pa

- Pl :

-

Longitudinal tube pitch

- Pp :

-

Perforated pitch

- Ppp :

-

Pumping power

- Pt :

-

Transverse tube pitch

- Re:

-

Reynolds number

- ti :

-

Insert thickness

- T:

-

Temperature ˚C

- TiO2 :

-

Titanium oxide

- W:

-

Width of tape

- Y:

-

Twisted pitch

- k:

-

Thermal conductivity, W m−1 K−1

- \({\upmu }\) :

-

Dynamic viscosity (Pa. s)

- ρ:

-

Density (kg m−3)

- φ:

-

Volume fraction

- CF:

-

Colburn factor

- VFR:

-

Volume flow rate

- HX:

-

Heat exchanger

- PEC:

-

Performance evaluation criteria

- PT:

-

Plain tube

- PTTI:

-

Perforated twisted turbulator insert

- SI:

-

Sustainability index

- THNF:

-

Ternary hybrid nanofluid

- TTI:

-

Twisted Turbulator insert

- a:

-

Air

- p:

-

Pump

- pp:

-

Pumping power

- eff:

-

Effective

- f:

-

Fluid

- fi:

-

Fluid inlet

- ai:

-

Air inlet

- ao:

-

Air outlet

- e:

-

Exit

- max:

-

Maximum

- gen:

-

Generation

References

Levin ML, Miller MA. Maxwell’s treatise on electricity and magnetism. Sov Phys Uspekhi. 1981;24(11):904.

Manglik RM, Bergles AE (1993) Heat transfer and pressure drop correlations for twisted-tape inserts in isothermal tubes: Part II—Transition and turbulent flows. 890–896

Choi SU, Eastman JA (1995) Enhancing thermal conductivity of fluids with nanoparticles. Argonne National Lab.(ANL), Argonne, IL (United States). No. ANL/MSD/CP-84938; CONF-951135–29

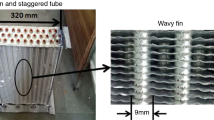

Wang CC, Fu WL, Chang CT. Heat transfer and friction characteristics of typical wavy fin-and-tube heat exchangers. Exp Therm Fluid Sci. 1997;14(2):174–86.

Madhu M, Shashikumar NS, Gireesha BJ, Kishan N. Thermal analysis of MHD powell-eyring fluid flow through a vertical microchannel. Int J Ambient Energy. 2022;43(1):4454–62.

Eiamsa-Ard S, Wongcharee K, Eiamsa-Ard P, Thianpong C. Thermohydraulic investigation of turbulent flow through a round tube equipped with twisted tapes consisting of center wings and alternate axes. Exp Therm Fluid Sci. 2010;34(8):1151–61.

Eiamsa-Ard S, Seemawute P, Wongcharee K. Influences of peripherally-cut twisted tape insert on heat transfer and thermal performance characteristics in laminar and turbulent tube flows. Exp Therm Fluid Sci. 2010;34(6):711–9.

Caliskan H, Dincer I, Hepbasli A. Exergoeconomic, enviroeconomic and sustainability analyses of a novel air cooler. Energy Build. 2012;55:747–56.

Gireesha BJ, Keerthi ML. Effect of periodic heat transfer on the transient thermal behavior of a convective-radiative fully wet porous moving trapezoidal fin. Appl Math Mech. 2023;44(4):653–68.

Kannan C, Jayasingh TR, Vinoth M, Vijayakumar T. An experimental study on the influence of operating parameters on the heat transfer characteristics of an automotive radiator with nanofluids. Int J Recent Trends Mech Eng. 2014;2:7–11.

Gireesha BJ, Mahanthesh B, Shivakumara IS, Eshwarappa KM. Melting heat transfer in boundary layer stagnation-point flow of nanofluid toward a stretching sheet with an induced magnetic field. Eng Sci Technol Int J. 2016;19(1):313–21.

Khan A, Ali HM, Nazir R, Ali R, Munir A, Ahmad B, Ahmad Z. Experimental investigation of enhanced heat transfer of a car radiator using ZnO nanoparticles in H2O–ethylene glycol mixture. J Therm Anal Calorim. 2019;138(5):3007–21.

Xian HW, Sidik NA, Najafi GJ. Recent state of nanofluid in automobile cooling systems. J Therm Anal Calorim. 2019;135:981–1008.

Selvam C, Lal DM, Harish S. Enhanced heat transfer performance of an automobile radiator with graphene based suspensions. Appl Therm Eng. 2017;123:50–60.

Ahmed SA, Ozkaymak M, Sözen A, Menlik T, Fahed A. Improving car radiator performance by using TiO2-water nanofluid. Eng Sci Technol Int J. 2018;21(5):996–1005.

Nakhchi ME, Esfahani JA. Cu-water nanofluid flow and heat transfer in a heat exchanger tube equipped with cross-cut twisted tape. Powder Technol. 2018;339:985–94.

Krishnamurthy MR, Prasannakumara BC, Gireesha BJ, Gorla RS. Effect of chemical reaction on MHD boundary layer flow and melting heat transfer of Williamson nanofluid in porous medium. Eng Sci Technol Int J. 2016;19(1):53–61.

Contreras EM, Oliveira GA, Bandarra Filho EP. Experimental analysis of the thermohydraulic performance of graphene and silver nanofluids in automotive cooling systems. Int J Heat Mass Transf. 2019;132:375–87.

Nakhchi ME, Esfahani JA. Numerical investigation of rectangular-cut twisted tape insert on performance improvement of heat exchangers. Int J Therm Sci. 2019;138:75–83.

Abbas F, Ali HM, Shah TR, Babar H, Janjua MM, Sajjad U, Amer M. Nanofluid: Potential evaluation in automotive radiator. J Mol Liq. 2020;297:112014.

Bucak H, Yılmaz F. The current state on the thermal performance of twisted tapes: A geometrical categorisation approach. Chem Eng Process-Process Intensif. 2020;153:107929.

Chu WX, Tsai CA, Lee BH, Cheng KY, Wang CC. Experimental investigation on heat transfer enhancement with twisted tape having various V-cut configurations. Appl Therm Eng. 2020;172:115148.

Kumar V, Sahoo RR. Exergy and energy performance for wavy fin radiator with a new coolant of various shape nanoparticle-based hybrid nanofluids. J Therm Anal Calorim. 2021;143:3911–22.

Dagdevir T, Ozceyhan V. An experimental study on heat transfer enhancement and flow characteristics of a tube with plain, perforated and dimpled twisted tape inserts. Int J Therm Sci. 2021;159:106564.

Xuan Z, Zhai Y, Ma M, Li Y, Wang H. Thermo-economic performance and sensitivity analysis of ternary hybrid nanofluids. J Mol Liq. 2021;323:114889.

Kashyap S, Sarkar J, Kumar A. Performance enhancement of regenerative evaporative cooler by surface alterations and using ternary hybrid nanofluids. Energy. 2021;225:120199.

Nakhchi ME, Esfahani JA. Numerical investigation of turbulent CuO–water nanofluid inside heat exchanger enhanced with double V-cut twisted tapes. J Therm Anal Calorim. 2021;145:2535–45.

Kumar V, Sahoo RR. 4 E’s (energy, exergy, economic, environmental) performance analysis of air heat exchanger equipped with various twisted turbulator inserts utilizing ternary hybrid nanofluids. Alex Eng J. 2022;61(7):5033–50.

Kumar V, Sahoo RR. Analysis of heat exchanger equipped with various twisted turbulator inserts utilizing tripartite hybrid nanofluids. J Therm Anal Calorim. 2022;147(19):10845–63.

Shajahan MI, Stephen C, Michael JJ, Arulprakasajothi M, Rathnakumar P, Parthasarathy M. Heat transfer investigations of in-line conical strip inserts using MWCNT/water nanofluid under laminar flow condition. Int J Therm Sci. 2023;183:107844.

Bairagi S, Roy R, Mandal BK. Heat transfer enhancement in laminar pipe flow using Al2o3–water nanofluid and twisted tape inserts. J Therm Sci Eng Appl. 2023;15(8):081003.

Said Z, Assad ME, Hachicha AA, Bellos E, Abdelkareem MA, Alazaizeh DZ, Yousef BA. Enhancing the performance of automotive radiators using nanofluids. Renew Sustain Energy Rev. 2019;112:183–94.

Rosen MA, Dincer I, Kanoglu M. Role of exergy in increasing efficiency and sustainability and reducing environmental impact. Energy Policy. 2008;36(1):128–37.

Webb RL. Performance evaluation criteria for use of enhanced heat transfer surfaces in heat exchanger design. Int J Heat Mass Transf. 1981;24(4):715–26.

Saysroy A, Eiamsa-Ard S. Enhancing convective heat transfer in laminar and turbulent flow regions using multi-channel twisted tape inserts. Int J Therm Sci. 2017;1(121):55–74.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that no known financial interest influences the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rai, R., Kumar, V. & Sahoo, R.R. Energy, exergy-emission performance investigation of heat exchanger with Turbulators inserts and ternary hybrid nanofluid. J Therm Anal Calorim 149, 3999–4017 (2024). https://doi.org/10.1007/s10973-024-12934-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-024-12934-x