Abstract

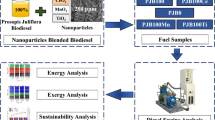

This study investigates the exergetic and exergoeconomic analyses of a diesel engine operated on dual-fuel mode with fuelled both diesel fuel–boron nitride nanofuel and biogas purchased commercially. The experiments were performed for diesel fuel, diesel + 100 ppm boron nitride nanoparticle, diesel + 100 ppm boron nitride nanoparticle + 0.5 L min−1 biogas, diesel + 100 ppm boron nitride nanoparticle + 1.0 L min−1 biogas and diesel + 100 ppm boron nitride nanoparticle + 2.0 L min−1 biogas at various engine loads (2.5 Nm, 5.0 Nm, 7.5 Nm, and 10.0 Nm) and fixed crankshaft speed of 1500 rpm. The obtained experimental data were used to realize exergetic and exergoeconomic analyses. Among the fuels considered in this study, diesel + 100 ppm boron nitride nanoparticle nanofuel had the best exergetic and exergoeconomic results. As a result, at engine load of 10 Nm, the exergy efficiency of test engine and specific exergy cost of crankshaft work were obtained to be 29.12% and 124.86 US$ GJ−1 for diesel + 100 ppm boron nitride nanoparticle nanofuel, respectively. These values were 27.35% and 125.19 US$ GJ−1 for diesel fuel, 25.50% and 141.92 US$ GJ−1 for diesel + 100 ppm boron nitride nanoparticle + 0.5 L min−1 biogas, 23.10% and 156.33 US$ GJ−1 for diesel + 100 ppm boron nitride nanoparticle + 1.0 L min−1 biogas, and 21.09% and 171.92 US$ GJ−1 for diesel + 100 ppm boron nitride nanoparticle + 2.0 L min−1 biogas, respectively. It is clear that biogas addition to combustion made worse the exergetic and exergoeconomic performances of test engine. As a conclusion, it can be said that diesel + 100 ppm boron nitride nanoparticle nanofuel can be used as alternative fuel to D100 in terms of exergy and exergoeconomics.

Similar content being viewed by others

Abbreviations

- \(c\) :

-

Specific exergy cost ($ GJ−1)

- \(C\) :

-

Mass fraction of carbon ($ h−1)

- \(\dot{C}\) :

-

Cost flow rate (US$ h−1)

- c p :

-

Specific heat capacity at constant pressure (kJ kg−1 K−1)

- CRF:

-

Capital recovery factor (−)

- ex:

-

Specific exergy rate (kJ kg−1)

- \({\text{E}\dot{\text{x}}}\) :

-

Exergy rate (kW)

- \(H\) :

-

Mass fraction of hydrogen (-)

- \(i\) :

-

Interest rate (-)

- LHV:

-

Lower heating value (kJ kg−1)

- \(\dot{m}\) :

-

Mass flow rate (kg s−1)

- \(M\) :

-

Molar mass (kg kmol−1)

- n :

-

Crankshaft speed (rpm)

- \(\dot{n}\) :

-

Molar flow rate (kmol s−1)

- \(N\) :

-

Lifetime (year)

- \(O\) :

-

Mass fraction of oxygen (-)

- \(P\) :

-

Pressure (kPa)

- PEC:

-

Purchased equipment cost (US$)

- \(\dot{Q}\) :

-

Heat transfer rate (kW)

- \(R\) :

-

Gas constant (kJ kg−1 K−1)

- \(\tilde{R}\) :

-

Universal gas constant (kJ kmol−1 K−1)

- \(t\) :

-

Annual operating hours (h)

- \(T\) :

-

Temperature (K)

- T :

-

Torque (Nm)

- \(y\) :

-

Molar fraction (−)

- \(\dot{Z}\) :

-

Capital investment cost rate (US$ h−1)

- \(\alpha\) :

-

Mass fraction of sulphur (−)

- \(\tau\) :

-

Maintenance factor (−)

- \(\varphi\) :

-

Chemical exergy factor (−)

- \(\psi\) :

-

Exergetic efficiency (%)

- \(\omega\) :

-

Angular velocity (rad s−1)

- ch:

-

Chemical

- D:

-

Destruction

- exh:

-

Exhaust

- tm:

-

Thermomechanical

- W:

-

Work

- 0:

-

Reference state

References

Child M, Nordling A, Breyer C. Scenarios for a sustainable energy system in the Åland Islands in 2030. Energy Convers Manag. 2017;137:49–60.

Saidur R, Islam MR, Rahim NA, Solangi KH. A review on global wind energy policy. Renew Sustain Energy Rev. 2010;14:1744–62.

Solangi KH, Islam MR, Saidur R, Rahim NA, Fayaz H. A review on global solar energy policy. Renew Sustain Energy Rev. 2011;15:2149–63.

McDowall W, Eames M. Towards a sustainable hydrogen economy: a multi-criteria sustainability appraisal of competing hydrogen futures. Int J Hydrog Energy. 2007;32:4611–22.

González-Montaña JR, Diez AJA, Alonso de la Varga ME, Téllez SA. Transportation sector energy consumption. Internacional de Ovinocultura, Asociacion Mexicana de Especialistas en Ovinocultura; 2016. p. 127–37.

Ağbulut Ü, Sarıdemir S, Rajak U, Polat F, Afzal A, Verma TN. Effects of high-dosage copper oxide nanoparticles addition in diesel fuel on engine characteristics. Energy. 2021;229: 120611.

Imdadul HK, Masjuki HH, Kalam MA, Zulkifli NWM, Rashed MM, Rashedul HK, Monirul IM, Mosarof MH. A comprehensive review on the assessment of fuel additive effects on combustion behavior in CI engine fuelled with diesel biodiesel blends. RSC Adv. 2015;5:67541–67.

Ağbulut Ü, Karagoz M, Saridemir S, Öztürk A. Impact of various metal-oxide based nanoparticles and biodiesel blends on the combustion, performance, emission, vibration and noise characteristics of a CI engine. Fuel. 2020;270: 117521.

Jiaqiang E, Zhang Z, Chen J, Pham MH, Zhao X, Peng Q, Zhang B, Yin Z. Performance and emission evaluation of a marine diesel engine fueled by water biodiesel-diesel emulsion blends with a fuel additive of a cerium oxide nanoparticle. Energy Convers Manag. 2018;169:194–205.

El-Seesy AI, Xuan T, He Z, Hassan H. Enhancement the combustion aspects of a CI engine working with Jatropha biodiesel/decanol/propanol ternary combinations. Energy Convers Manag. 2020;226: 113524.

Nour M, Sun Z, El-Seesy AI, Li X. Experimental evaluation of the performance and emissions of a direct-injection compression-ignition engine fueled with n-hexanol–diesel blends. Fuel. 2021;302: 121144.

El-Seesy AI, Waly MS, He Z, El-Batsh HM, Nasser A, El-Zoheiry RM. Influence of quaternary combinations of biodiesel/methanol/n-octanol/diethyl ether from waste cooking oil on combustion, emission, and stability aspects of a diesel engine. Energy Convers Manag. 2021;240: 114268.

El-Seesy AI, Waly MS, El-Batsh HM, El-Zoheiry RM. Enhancement of the waste cooking oil biodiesel usability in the diesel engine by using n-decanol, nitrogen-doped, and amino-functionalized multi-walled carbon nanotube. Energy Convers Manag. 2023;277: 116646.

Dehhaghi M, Panahi HKS, Aghbashlo M, Lam SS, Tabatabaei M. The effects of nanoadditives on the performance and emission characteristics of spark-ignition gasoline engines: a critical review with a focus on health impacts. Energy. 2021;225: 120259.

El-Seesy AI, Nour M, Hassan H, Elfasakhany A, He Z, Mujtaba MA. Diesel-oxygenated fuels ternary blends with nano additives in compression ignition engine: a step towards cleaner combustion and green environment. Case Stud Therm Eng. 2021;25: 100911.

Fayaz H, Mujtaba MA, Soudagar MEM, Razzaq L, Nawaz S, Nawaz MA, Farooq M, Afzal A, Ahmed W, Khan TMY, Bashir S, Yaqoob H, El-Seesy AI, Wageh S, Al-Ghamdi A, Elfasakhany A. Collective effect of ternary nano fuel blends on the diesel engine performance and emissions characteristics. Fuel. 2021;293: 120420.

Waly MS, El-Seesy AI, El-Batsh HM, El-Zoheiry RM. Combustion and emissions characteristics of a diesel engine fuelled with diesel fuel and different concentrations of amino-functionalized multi-walled carbon nanotube. Atmos Pollut Res. 2023;14: 101831.

El-Seesy AI, Waly MS, He Z, El-Batsh HM, Nasser A, El-Zoheiry RM. Enhancement of the combustion and stability aspects of diesel-methanol-hydrous methanol blends utilizing n-octanol, diethyl ether, and nanoparticle additives. J Clean Prod. 2022;371: 133673.

Ojha PK, Karmakar S. Boron for liquid fuel engines—a review on synthesis, dispersion stability in liquid fuel, and combustion aspects. Prog Aerosp Sci. 2018;100:18–45.

Icten O, Zumreoglu-Karan B. Energetic aspects of elemental boron: a mini-review. Energy Sources Part A Recov Util Environ Effects. 2022;44:182–94.

Mehta RN, Chakraborty M, Parikh PA. Nanofuels: combustion, engine performance and emissions. Fuel. 2014;120:91–7.

Kul VS, Akansu SO. Experimental investigation of the impact of boron nanoparticles and CNG on performance and emissions of heavy-duty diesel engine. Fuel. 2022;324: 124470.

Polat F, Yeşilyurt MK, Ağbulut Ü, Karagoz M, Saridemir S. Experimental assessment of the influences of liquid–solid–gas fuel blends on DI-CI engine behaviors. Process Saf Environ Prot. 2022;159:511–24.

Ozer S, Demir U, Kocyigit S. Effect of using borax decahydrate as nanomaterials additive diesel fuel on diesel engine performance and emissions. Energy. 2023;266: 126412.

Ahmadi P, Dincer I, Rosen MA. Exergy, exergoeconomic and environmental analyses and evolutionary algorithm based multi-objective optimization of combined cycle power plants. Energy. 2011;36:5886–98.

Kotas TJ. The exergy method of thermal plant analysis. Anchor Brendon Ltd.; 1985.

Dogan B, Cakmak A, Yesilyurt MK, Erol D. Investigation on 1-heptanol as an oxygenated additive with diesel fuel for compression-ignition engine applications: an approach in terms of energy, exergy, exergoeconomic, and sustainability analyses. Fuel. 2020;275: 117973.

Uysal C, Uslu S, Aydin M. Exergetic and exergoeconomic analyses of a diesel engine fueled with binary and ternary blends of diesel-palm oil biodiesel-diethyl ether for various injection timings. J Therm Anal Calorimet. 2022;147:12641–59.

Cavalcanti EJC, Carvalho M, Ochoa AAV. Exergoeconomic and exergoenvironmental comparison of diesel-biodiesel blends in a direct injection engine at variable loads. Energy Convers Manag. 2019;183:450–61.

Dogan B, Ozer S, Erol D. Exergy, exergoeconomic, and exergoenviroeconomic evaluations of the use of diesel/fusel oil blends in compression ignition engines. Sustain Energy Technol Assess. 2022;53: 102475.

Saha D, Roy B. Effects of plastic-grocery-bag derived oil-water-diesel emulsions on combustion, performance and emission characteristics, and exergoeconomic aspects of compression ignition engine. Sustain Energy Technol Assess. 2022;54: 102877.

Karagoz M, Uysal C, Agbulut U, Saridemir S. Energy, exergy, economic and sustainability assessments of a compression ignition diesel engine fueled with tire pyrolytic oil-diesel blends. J Clean Prod. 2020;264: 121724.

Aghbashlo M, Tabatabaei M, Khalife E, Shojaei TR, Dadak A. Exergoeconomic analysis of a DI diesel engine fueled with diesel/biodiesel (B5) emulsions containing aqueous nano cerium oxide. Energy. 2018;149:967–78.

Karagoz M, Uysal C, Agbulut U, Saridemir S. Exergetic and exergoeconomic analyses of a CI engine fueled with diesel-biodiesel blends containing various metal-oxide nanoparticles. Energy. 2021;214: 118830.

Uysal C, Agbulut U, Elibol E, Demirci T, Karagoz M, Saridemir S. Exergetic, exergoeconomic, and sustainability analyses of diesel–biodiesel fuel blends including synthesized graphene oxide nanoparticles. Fuel. 2022;327: 125167.

Agbulut U, Uysal C, Cavalcanti EJC, Carvalho M, Karagoz M, Saridemir S. Exergy, exergoeconomic, life cycle, and exergoenvironmental assessments for an engine fueled by diesel–ethanol blends with aluminum oxide and titanium dioxide additive nanoparticles. Fuel. 2022;320: 123861.

Agbulut U. Understanding the role of nanoparticle size on energy, exergy, thermoeconomic, exergoeconomic, and sustainability analyses of an IC engine: a thermodynamic approach. Fuel Process Technol. 2022;225: 107060.

Verma S, Das LM, Kaushik SC. Effects of varying composition of biogas on performance and emission characteristics of compression ignition engine using exergy analysis. Energy Convers Manag. 2017;138:346–59.

Moran MJ, Shapiro HN. Fundamentals of engineering thermodynamics. New York: Wiley; 2000.

Bejan A, Tsatsaronis G, Moran M. Thermal design and optimization. New York: Wiley; 1996.

Lozano MA, Valero A. Theory of the exergetic cost. Energy. 1993;18:939–60.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Uysal, C., Ağbulut, Ü., Topal, H.I. et al. Exergetic and exergoeconomic assessments of a diesel engine operating on dual-fuel mode with biogas and diesel fuel containing boron nitride nanoparticles. J Therm Anal Calorim 149, 1185–1198 (2024). https://doi.org/10.1007/s10973-023-12763-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12763-4