Abstract

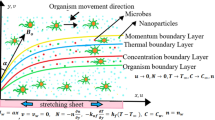

In recent times, the field of nanotechnology has been instrumental in driving significant breakthroughs in heat transport. These technological breakthroughs have shown their significance in improving the efficiency of heat exchangers, such as thermal pipes, microfluidic structures, and electronic components that depend on effective heat transfer processes. This study aims to explore innovative methods for enhancing heat transfer effectiveness. The present investigation focuses on the two-dimensional, incompressible, electrically conducting ternary liquid flow between two parallel porous plates in a microchannel. This has been considered with the convective boundary conditions employing the thermophoretic particle deposition phenomena. The numerical results of the mathematical, physical problem entailed a similar solution employed with the RKF-45 method. The stimulus of these process-sensitive non-dimensional parameters has been discussed and presented graphically with validation of the published results. The velocity profiles decline as increment in \(S_{1}\) and \(M_{{\text{F}}}\) whereas the thermal profile lessens with the augmentation in Biot numbers \({\text{Bi}}_{1} \;{\text{and}}\;{\text{Bi}}_{2}\). Moreover, the study emphasizes that the mass and thermal energy distribution rates exhibit a reduction when the solid volume percentage, thermophoretic constraints, and the existence of a porous medium increase. The ramifications of these discoveries are significant in terms of the design and optimization of microfluidic devices and thermal exchangers. The findings are visually shown using illustrations, offering valuable insights into the intricate relationships among the variables under investigation.

Similar content being viewed by others

Data availability

Data will be made available on reasonable request.

Abbreviations

- \(h\) :

-

Distance

- \(d\) :

-

Length

- \(V\) :

-

Wall suction/injection velocity

- \(u\) :

-

Axial velocity

- \(k_{1}\) :

-

Permeability of the porous media

- \(C_{{\text{p}}}\) :

-

Specific heat

- \(T\) :

-

Temperature

- \(D_{{\text{B}}}\) :

-

Diffusivity

- \(h_{1} ,h_{2}\) :

-

Convective heat transfer coefficient

- \(V_{{\text{T}}}\) :

-

Thermophoretic velocity

- \(\delta\) :

-

Thermophoretic coefficient

- \(T_{r1}\) :

-

Reference temperature

- \(P\) :

-

Pressure

- \(A*\) :

-

Pressure gradient parameter

- \({\text{Re}}\) :

-

Reynolds number

- \(\Pr\) :

-

Prandtl number

- \({\text{Ec}}_{1}\) :

-

Eckert number

- \(S_{1}\) :

-

Porous media shape factor

- \(M_{{\text{F}}}\) :

-

Magnetic field parameter

- \(\tau_{2}\) :

-

Thermophoretic parameter

- \({\text{Sc}}_{1}\) :

-

Schmidt number

- \({\text{Bi}}\) :

-

Biot number

- \(C_{{\text{f}}}\) :

-

Skin friction coefficient

- \({\text{Nu}}\) :

-

Nusselt number

- \({\text{Sh}}\) :

-

Sherwood number

- \(\rho\) :

-

Density

- \(k\) :

-

Thermal conductivity

- \(\theta\) :

-

Dimensionless temperature

- \(\delta\) :

-

Thermophoretic coefficient

- \(\mu\) :

-

Dynamic viscosity

- \(\sigma\) :

-

Electrical conductivity

- \(\chi\) :

-

Dimensionless concentration

- \(\phi\) :

-

Solid volume fraction

- \({\text{thnf}}\) :

-

Ternary nanofluid

- \({\text{nf}}\) :

-

Nanofluid

- \(\left. \begin{gathered} S1 \hfill \\ S2 \hfill \\ S3 \hfill \\ \end{gathered} \right\}\) :

-

Solid particles

- \({\text{hnf}}\) :

-

Hybrid nanofluid

- \(f\) :

-

Fluid

References

Choi SUS, Eastman JA. Enhancing thermal conductivity of fluids with nanoparticles. Argonne National Lab. (ANL), Argonne, IL (United States); 1995.

Lee S, Choi SU-S. Application of metallic nanoparticle suspensions in advanced cooling systems. American Society of Mechanical Engineers Digital Collection; 1996; p. 227–34.

Nguyen CT, Roy G, Gauthier C, Galanis N. Heat transfer enhancement using Al2O3–water nanofluid for an electronic liquid cooling system. Appl Therm Eng. 2007;27:1501–6.

Animasaun IL, Kumar TK, Noah FA, Okoya SS, Al-Mdallal QM, Bhatti MM. Insight into Darcy flow of ternary-hybrid nanofluid on horizontal surfaces: exploration of the effects of convective and unsteady acceleration. ZAMM J Appl Math Mech/Zeitschrift für Angewandte Mathematik und Mechanik. 2023;103: e202200197.

Sharma K, Vijay N, Ram D, Animasaun IL. Significance of geothermal viscosity for the magnetic fluid flow between co-rotating porous surfaces. Numer Heat Transf Part A Appl. 2023;84:980–91.

Wahid NS, Arifin NM, Pop I, Bachok N, Hafidzuddin MEH. MHD stagnation-point flow of nanofluid due to a shrinking sheet with melting, viscous dissipation and Joule heating effects. Alex Eng J. 2022;61:12661–72.

Shaw S, Khan MI, Nayak MK, Madhukesh JK, Kumar RSV, Farooq S, et al. Significance of buongiorno model and arrhenius pre-exponential factor law to entropy optimized darcy forchheimer hybrid nanoparticle (Al2O3, Cu) flow over thin needle. J Magn. 2021;26:363–77.

Chamkha AJ, Rashad AM, Al-Meshaiei E. Melting effect on unsteady hydromagnetic flow of a nanofluid past a stretching sheet. Int J Chem Reactor Eng. 2011. https://doi.org/10.2202/1542-6580.2613.

Pavithra KM, Srilatha P, Hanumagowda BN, Varma SVK, Verma A, Alkarni S, et al. A free convective two-phase flow of optically thick radiative ternary hybrid nanofluid in an inclined symmetrical channel through a porous medium. Symmetry. 2023;15:1615.

Shukla S, Sharma RP, Punith Gowda RJ, Prasannakumara BC. Elastic deformation effect on carboxymethyl cellulose water-based (TiO2–Ti6Al4V) hybrid nanoliquid over a stretching sheet with an induced magnetic field. Numer Heat Transf Part A Appl. 2023. https://doi.org/10.1080/10407782.2023.2175750.

Li J, Zhang X, Xu B, Yuan M. Nanofluid research and applications: a review. Int Commun Heat Mass Transfer. 2021;127: 105543.

Kharat PB, Kounsalye JS, Shisode MV, Jadhav KM. Preparation and thermophysical investigations of CoFe2O4-based nanofluid: a potential heat transfer agent. J Supercond Nov Magn. 2019;32:341–51.

Hozien O, El-Maghlany WM, Sorour MM, Mohamed YS. Experimental study on thermophysical properties of TiO2, ZnO and Ag water base nanofluids. J Mol Liq. 2021;334: 116128.

Afrand M, Toghraie D, Sina N. Experimental study on thermal conductivity of water-based Fe3O4 nanofluid: development of a new correlation and modeled by artificial neural network. Int Commun Heat Mass Transfer. 2016;75:262–9.

Ranga Babu JA, Kumar KK, Srinivasa RS. State-of-art review on hybrid nanofluids. Renew Sustain Energy Rev. 2017;77:551–65.

Yang L, Ji W, Mao M, Huang J. An updated review on the properties, fabrication and application of hybrid-nanofluids along with their environmental effects. J Clean Prod. 2020;257: 120408.

Rekha MB, Sarris IE, Madhukesh JK, Raghunatha KR, Prasannakumara BC. Activation energy impact on flow of AA7072-AA7075/water-based hybrid nanofluid through a cone. Wedge Plate Micromachines. 2022;13:302.

Oke AS, Prasannakumara BC, Mutuku WN, Gowda RJP, Juma BA, Kumar RN, et al. Exploration of the effects of Coriolis force and thermal radiation on water-based hybrid nanofluid flow over an exponentially stretching plate. Sci Rep. 2022;12:21733.

Rauf A, Ali Shah N, Mushtaq A, Botmart T. Heat transport and magnetohydrodynamic hybrid micropolar ferrofluid flow over a non-linearly stretching sheet. MATH. 2023;8:164–93.

Zubair M, Qureshi A, Faisal D-M, Raza Q, Ali B, Botmart T, et al. Morphological nanolayer impact on hybrid nanofluids flow due to dispersion of polymer/CNT matrix nanocomposite material. AIMS Math. 2022;8:633–56.

Adun H, Kavaz D, Dagbasi M. Review of ternary hybrid nanofluid: synthesis, stability, thermophysical properties, heat transfer applications, and environmental effects. J Clean Prod. 2021;328: 129525.

Sahoo RR, Kumar V. Development of a new correlation to determine the viscosity of ternary hybrid nanofluid. Int Commun Heat Mass Transfer. 2020;111: 104451.

Sahoo RR. Thermo-hydraulic characteristics of radiator with various shape nanoparticle-based ternary hybrid nanofluid. Powder Technol. 2020;370:19–28.

Animasaun IL, Yook S-J, Muhammad T, Mathew A. Dynamics of ternary-hybrid nanofluid subject to magnetic flux density and heat source or sink on a convectively heated surface. Surf Interfaces. 2022;28: 101654.

Puneeth V, Anandika R, Manjunatha S, Khan MI, Imran Khan M, Althobaiti A, et al. Implementation of modified Buongiorno’s model for the investigation of chemically reacting rGO-Fe3O4-TiO2-H2O ternary nanofluid jet flow in the presence of bio-active mixers. Chem Phys Lett. 2022;786: 139194.

Cao W, Animasaun IL, Yook SJ, Oladipupo VA, Ji X. Simulation of the dynamics of colloidal mixture of water with various nanoparticles at different levels of partial slip: Ternary-hybrid nanofluid. Int Commun Heat Mass Transf. 2022;135:106069.

Xiu W, Animasaun IL, Al-Mdallal QM, Alzahrani AK, Muhammad T. Dynamics of ternary-hybrid nanofluids due to dual stretching on wedge surfaces when volume of nanoparticles is small and large: forced convection of water at different temperatures. Int Commun Heat Mass Transf. 2022;137:106241.

Sharma RP, Madhukesh JK, Shukla S, Prasannakumara BC. Numerical and Levenberg–Marquardt backpropagation neural networks computation of ternary nanofluid flow across parallel plates with Nield boundary conditions. Eur Phys J Plus. 2023;138:63.

Rashad AM. Influence of radiation on MHD free convection from a vertical flat plate embedded in porous media with thermophoretic deposition of particles. Commun Nonlinear Sci Numer Simul. 2008;13:2213–22.

Chu Y-M, Khan N, Ijaz Khan M, Al-Khaled K, Abbas N, Ullah Khan S, et al. Thermophoresis particle deposition analysis for nonlinear thermally developed flow of Magneto-Walter’s B nanofluid with buoyancy forces. Alex Eng J. 2021;60:1851–60.

Madhukesh JK, Ramesh GK, Prasannakumara BC. Convective thermal conditions and the thermophoretic effect’s impacts on a hybrid nanofluid over a moving thin needle. Numer Methods Partial Differ Equ. 2023;39:1163–84.

Ramesh GK, Madhukesh JK, Ali Shah N, Yook S-J. Flow of hybrid CNTs past a rotating sphere subjected to thermal radiation and thermophoretic particle deposition. Alex Eng J. 2023;64:969–79.

Srilatha P, Abu-Zinadah H, Kumar RSV, Alsulami MD, Kumar RN, Abdulrahman A, et al. Effect of nanoparticle diameter in Maxwell nanofluid flow with thermophoretic particle deposition. Mathematics. 2023;11:3501.

Saif RS, Muhammad T, Sadia H. Significance of inclined magnetic field in Darcy-Forchheimer flow with variable porosity and thermal conductivity. Physica A. 2020;551: 124067.

Hayat T, Haider F, Alsaedi A, Ahmad B. Unsteady flow of nanofluid through porous medium with variable characteristics. Int Commun Heat Mass Transf. 2020;119: 104904.

Eswaramoorthi S, Loganathan K, Faisal M, Botmart T, Shah NA. Analytical and numerical investigation of Darcy-Forchheimer flow of a nonlinear-radiative non-Newtonian fluid over a Riga plate with entropy optimization. Ain Shams Eng J. 2023;14: 101887.

Madhukesh JK, Kalleshachar V, Kumar C, Khan U, Nagaraja KV, Sarris IE, et al. A model development for thermal and solutal transport analysis of non-Newtonian nanofluid flow over a riga surface driven by a waste discharge concentration. Water. 2023;15:2879.

Khan U, Zaib A, Ishak A, Sherif E-SM, Waini I, Chu Y-M, et al. Radiative mixed convective flow induced by hybrid nanofluid over a porous vertical cylinder in a porous media with irregular heat sink/source. Case Stud Therm Eng. 2022;30:101711.

Blasius H. Grenzschichten in Flüssigkeiten mit kleiner Reibung. Druck von B.G: Teubner; 1907.

Zainal NA, Nazar R, Naganthran K, Pop I. MHD mixed convection stagnation point flow of a hybrid nanofluid past a vertical flat plate with convective boundary condition. Chin J Phys. 2020;66:630–44.

Khashiie NS, Arifin NM, Pop I, Nazar R, Hafidzuddin EH, Wahi N. Three-dimensional hybrid nanofluid flow and heat transfer past a permeable stretching/shrinking sheet with velocity slip and convective condition. Chin J Phys. 2020;66:157–71.

Madhu M, Mahanthesh B, Shashi Kumar NS, Shehzad SA, Khand SU, Gireesha BJ. Performance of second law in Carreau fluid flow by an inclined microchannel with a radiative heated convective condition. Int Commun Heat Mass Transf. 2020;117:104761.

López A, Ibáñez G, Pantoja J, Moreira J, Lastres O. Entropy generation analysis of MHD nanofluid flow in a porous vertical microchannel with nonlinear thermal radiation, slip flow and convective-radiative boundary conditions. Int J Heat Mass Transf. 2017;107:982–94.

Ibáñez G. Entropy generation in MHD porous channel with hydrodynamic slip and convective boundary conditions. Int J Heat Mass Transf. 2015;80:274–80.

Sindhu S, Gireesha BJ. Heat and mass transfer analysis of chemically reactive tangent hyperbolic fluid in a microchannel. Heat Transf. 2021;50:1410–27.

Epstein M, Hauser GM, Henry RE. Thermophoretic deposition of particles in natural convection flow from a vertical plate. J Heat Transf. 1985;107:272–6.

Devi Sathyanarayanan SU, Mabood F, Jamshed W, Mishra SR, Nisar K, Pattnaik PK, et al. Irreversibility process characteristics of variant viscosity and conductivity on hybrid nanofluid flow through Poiseuille microchannel: a special case study. Case Stud Therm Eng. 2021;27:101337.

Ramzan M, Dawar A, Saeed A, Kumam P, Sitthithakerngkiet K, Lone SA. Analysis of the partially ionized kerosene oil-based ternary nanofluid flow over a convectively heated rotating surface. Open Phys. 2022;20:507–25.

Chu Y-M, Nisar KS, Khan U, Daei Kasmaei H, Malaver M, Zaib A, et al. Mixed convection in MHD water-based molybdenum disulfide-graphene oxide hybrid nanofluid through an upright cylinder with shape factor. Water. 2020;12:1723.

Waini I, Khan U, Zaib A, Ishak A, Pop I. Thermophoresis particle deposition of CoFe2O4-TiO2 hybrid nanoparticles on micropolar flow through a moving flat plate with viscous dissipation effects. Int J Numer Meth Heat Fluid Flow. 2022;32:3259–82.

Hayat T, Rashid M, Alsaedi A. MHD convective flow of magnetite-Fe3O4 nanoparticles by curved stretching sheet. Results Phys. 2017;7:3107–15.

Nayak MK, Prakash J, Tripathi D, Pandey VS. 3D radiative convective flow of ZnO-SAE50nano-lubricant in presence of varying magnetic field and heterogeneous reactions. Propuls Power Res. 2019;8:339–50.

Ferdows M, Alam J, Murtaza G, Tzirtzilakis EE, Sun S. Biomagnetic flow with CoFe2O4 magnetic particles through an unsteady stretching/shrinking cylinder. Magnetochemistry. 2022;8:27.

Makinde OD, Eegunjobi AS. Effects of convective heating on entropy generation rate in a channel with permeable walls. Entropy. 2013;15:220–33.

Acknowledgements

The author would like to extend his appreciation to the Deanship of Scientific Research at King Khalid University, Saudi Arabia for funding this work through the Research Group Program under grant No. RGP.2/218/44.

Author information

Authors and Affiliations

Contributions

RPS and M developed the theoretical formalism and writing—original draft preparation. The authors SS, FG, P have performed the numerical simulations, validation, formal analysis and investigation. All authors discussed the results and contributed to the final manuscript. RPS and P supervised the findings of this work.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sharma, R.P., Madhukesh, J.K., Shukla, S. et al. Numerical study of the thermophoretic velocity of ternary hybrid nanofluid in a microchannel bounded by the two parallel permeable flat plates. J Therm Anal Calorim 148, 14069–14080 (2023). https://doi.org/10.1007/s10973-023-12691-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12691-3