Abstract

A wide range of industrial processes (i.e., evaporation and condensation in desalination process, steam power plant, solar plant, etc.) involve heat transfer among the fluids. During the process of evaporative and cooling heat transfer, undesirable materials from the fluids accumulate on the surfaces, which critically reduces the performance of heat exchangers and creates one of the biggest challenges in energy transfer. Though the various studies on prediction and removal of fouling was conducted by numerous scientists, this problem is still unresolved in industrial process and is responsible for huge environmental damage and economic losses. This investigation provides a comprehensive overview of crystallization fouling in heat exchangers. Various factors affecting the deposition of crystallization foulaning such as fluid temperature, flow velocity, surface material and roughness, concentration and boiling are systematically reviewed. Accuracy and uncertainty of different equipment and experimental studies are discussed. In addition, fouling modelling is comprehensively discussed from earlier fundamental model to recent computational fluid dynamic and artificial neural networks model. Furthermore, mitigation of fouling with off-line and online approaches are chronologically discussed. Finally, an overview from environmental and economic prospective of fouling in heat exchangers are discussed. The future directions for crystallization fouling in heat exchangers are emphasized, which will support the researchers and industries to retard fouling and achieve economic benefits.

Similar content being viewed by others

Abbreviations

- A :

-

Surface area (m2)

- C :

-

Concentration (gL−1)

- D :

-

Diffusion coefficient (m2s−1)

- \(\Delta E_{12}^{{{\text{TOT}}}}\) :

-

Total interaction energy (J)

- h :

-

Convection heat transfer coefficient (Wm−2 K−1)

- K m :

-

Fluid deposit mass transfer coefficient (ms−1)

- K r :

-

Rate of reaction (m4kg−1 s−1)

- \(K_{{\text{s}}}^{\prime }\) :

-

Deposit solubility product

- m :

-

Mass (kg)

- ṁ :

-

Mass flow rate (kg s−1)

- n :

-

Order of reaction

- Q :

-

Heat (J)

- R :

-

Thermal resistance (m2KW−1)

- Ra :

-

Arithmetic mean aberration

- Re:

-

Reynold number

- Rz :

-

Average surface roughness depth (µm)

- Sh:

-

Sherwood number

- t :

-

Time (s)

- T :

-

Temperature (K, °C)

- U :

-

Overall heat transfers coefficient (Wm−2 K−1)

- v :

-

Velocity (ms−1)

- Wa* :

-

Work of adhesion

- x :

-

Thickness (m)

- ƛ :

-

Thermal Conductivity, Wm K−1

- β :

-

Inverse of time constant, s−1

- τ :

-

Shear stress, Nm−2

- ρ :

-

Density, kg m−3

- * :

-

Asymptotic

- b:

-

Bulk solution

- c:

-

Clean

- d:

-

Deposit

- f:

-

Fouling

- r:

-

Removal

- sat:

-

Saturation

- ANN:

-

Artificial neural network

- AEMF:

-

Altering electromagnetic field

- ANNM:

-

Artificial neural network model

- CFD:

-

Computational fluid dynamic

- DTPA:

-

Diethylene triamine pentaacetate

- EAF:

-

Electronic antifouling

- EDM:

-

Electric discharge machining

- EDTA:

-

Ethylenediaminetetraacetic acid

- FFNN:

-

Feed-forward neural network

- GDP:

-

Gross domestic product

- GNP:

-

Gross national product

- MWCNT:

-

Multi-walled carbon nanotubes

- PTFE:

-

Polytetrafluoroethylene

- SCMC:

-

Sodium carboxymethyl cellulose

- SEM:

-

Scanning electron microscopy

- SWRO:

-

Sea water reverse osmosis

- US:

-

Ultrasonic

- USD:

-

United States dollar

- VG:

-

Vortex generator

- XRD:

-

X-ray diffraction

References

Helalizadeh A, Müller-Steinhagen H, Jamialahmadi M. Mixed salt crystallisation fouling. Chem Eng Process Process Intensif. 2000;39:29–43.

Arasteh H, Mashayekhi R, Ghaneifar M, Toghraie D, Afrand M. Numerical simulation of heat transfer enhancement in a plate-fin heat exchanger using a new type of vortex generators. J Therm Anal Calorim. 2020;141:1669–85. https://doi.org/10.1007/s10973-019-08870-w.

Kazi SN, Duffy GG, Chen XD. Mineral scale formation and mitigation on metals and a polymeric heat exchanger surface. Appl Therm Eng. 2010;30:2236–42. https://doi.org/10.1016/j.applthermaleng.2010.06.005.

Zhao X, Chen XD. A Critical Review of basic crystallography to salt crystallization fouling in heat exchangers. Heat Transf Eng. 2013;34:719–32.

Berce J, Zupančič M, Može M, Golobič I. A review of crystallization fouling in heat exchangers. Processes. 2021;9:66.

Bott TR. Fouling Note Book [Internet]. Rugby United Kingdom; 1990. https://www.osti.gov/etdeweb/biblio/5299249.

Albert F, Augustin W, Scholl S. Roughness and constriction effects on heat transfer in crystallization fouling. Chem Eng Sci. 2011;66:499–509. https://doi.org/10.1016/j.ces.2010.11.021.

Förster M, Augustin W, Bohnet M. Influence of the adhesion force crystal/heat exchanger surface on fouling mitigation. Chem Eng Process Process Intensif. 1999;38:449–61.

Helalizadeh A, Müller-Steinhagen H, Jamialahmadi M. Mathematical modelling of mixed salt precipitation during convective heat transfer and sub-cooled flow boiling. Chem Eng Sci. 2005;60:5078–88.

Bansal B, Chen XD, Muller-Steinhagen H. Deposition and removal mechanisms during calcium sulfate fouling in heat exchangers. Int J Transp Phenom. 2005;7:1–22.

Heberle A, Schaber K. Modeling of fouling on packings in absorption columns. AIChE J. 2002;48:2722–31.

Muller-Steinhagen H. The ultimate challenge for heat exchanger design. In: 6th International symposium transport phenomena thermal engineering. Seoul Korea; 1993. p. 811–23.

Kazi SN. Fouling and fouling mitigation of calcium compounds on heat exchangers by novel colloids and surface modifications. Rev Chem Eng. 2020;36:653–85.

Vosough A, Assari MR, Peyghambarzadeh SM. Experimental measurement of heat transfer coefficient and mass of deposited CaSO4 in subcooled flow boiling condition. J Comput Appl Mech. 2019;50:308–14.

Oon CS, Kazi SN, Hakimin MA, Abdelrazek AH, Mallah AR, Low FW, et al. Heat transfer and fouling deposition investigation on the titanium coated heat exchanger surface. Poweder Technol. 2020;373:671–80. https://doi.org/10.1016/j.powtec.2020.07.010.

Song KS, Lim J, Yun S, Kim D, Kim Y. Composite fouling characteristics of CaCO3 and CaSO4 in plate heat exchangers at various operating and geometric conditions. Int J Heat Mass Transf. 2019;136:555–62. https://doi.org/10.1016/j.ijheatmasstransfer.2019.03.032.

Singh A. Heat Exchanger Fouling By Precipitation Of Calcium Phosphates By Atmajeet Singh B. Tech., Indian Institute of Technology, New Delhi, India; A Thesis in Partial Fulfilment of the Requirements for the Degree of Master of Applied Science in the Faculty Office; 1992.

Kern D. A theoretical analysis of thermal surface fouling. Br Chem Eng. 1959;4:258–62.

Kazi MSN. Heat transfer to fibre suspensions: studies in fibre characterisation and fouling mitigation. University of Aukland; 2001.

Epstein N. Thinking about heat transfer fouling: a 5 × 5 matrix. Heat Transf Eng. 1983;4:43–56.

Kazi SN. Water-formed deposits fundamentals and mitigation strategies. Koch A, editor. Susan Dennis; 2022.

Taborek J, Hewitt GF, Afgan N. Heat exhangers: theory and practice. Washington, DC: Hemisphere Publishing Corp; 1983.

Melo LF, Bott TR, Berando CA. Fouling science and technology. North Atl Treaty Organ Sci Aff Div [Internet]. Alvor, Algarve, Portugal; 1988. https://www.worldcat.org/title/fouling-science-and-technology/oclc/17954359

Shah RK. Research needs in low Reynolds number flow heat exchangers. Heat Transf Eng. 1981;3:49–61.

Coletti F, Crittenden BD, Macchietto S. Basic science of the fouling process. Crude Oil Fouling Depos Charact Meas Model. 2015. https://doi.org/10.1016/B978-0-12-801256-7.00002-6.

Geddert T, Bialuch I, Augustin W, Scholl S. Extending the induction period of crystallization fouling through surface coating. Heat Transf Eng. 2009;30:868–75.

Pugh SJ, Hewitt GF, Müller-Steinhagen H. Fouling during the use of seawater as coolant—the development of a user guide. Heat Transf Eng. 2005;26:35–43.

Kazi SN. Fouling and fouling mitigation on heat exchanger surfaces. Heat Exch Basics Des Appl. 2012;66:6.

Besevic P, Clarke SM, Kawaley G, Wilson DI. Effect of silica on deposition and ageing of calcium carbonate fouling layers. Heat Exch Fouling Clean. 2017;66:58–66.

Sileri D, Sahu K, Ding H, Matar OK. Mathematical modelling of asphatenes deposition and removal in crude distillation units. In: International conference heat exchange fouling Clean VIII. 2009. p. 245–51.

Lv Y, Lu K, Ren Y. Composite crystallization fouling characteristics of normal solubility salt in double-pipe heat exchanger. Int J Heat Mass Transf. 2020;66:156.

Choi Y, Naidu G, Jeong S, Lee S, Vigneswaran S. Effect of chemical and physical factors on the crystallization of calcium sulfate in seawater reverse osmosis brine. Desalination. 2018;426:78–87. https://doi.org/10.1016/j.desal.2017.10.037.

Chong TH, Sheikholeslami R. Thermodynamics and kinetics for mixed calcium carbonate and calcium sulfate precipitation. Chem Eng Sci. 2001;56:5391–400.

Al-Gailani A, Sanni O, Charpentier TVJ, Crisp R, Bruins JH, Neville A. Examining the effect of ionic constituents on crystallization fouling on heat transfer surfaces. Int J Heat Mass Transf. 2020;160:120180. https://doi.org/10.1016/j.ijheatmasstransfer.2020.120180.

Krömer K, Will S, Loisel K, Nied S, Detering J. Scale formation and mitigation of mixed salts in horizontal tube falling film evaporators for seawater desalination scale formation and mitigation of mixed salts in horizontal tube falling film evaporators for seawater desalination. Heat Transf Eng. 2015;66:37–41.

Lugo-Granados H, Tamakloe EK, Picón-Núñez M. Controlling scaling in heat exchangers through the use of fouling design curves. Process Integr Optim Sustain. 2020;4:111–20.

Kazi SN, Duffy GG, Chen XD. Fouling and fouling mitigation on different heat exchanging. In: Proceedings of the international conference heat exchange fouling cleaning VIII—2009. 2009. p. 367–77.

Hou TK. Fouling and its mitigation on heat exchanger surfaces by additives and catalytic materials Teng Kah Hou A thesis submitted in partial fulfillment of the requirements of Liverpool John Moores University for the degree of Doctor of Philosophy This research; 2018.

Höfling V, Augustin W, Bohnet M. Heat exchanger fouling and cleaning: fundamentals and applications crystallization fouling of the aqueous. 2003.

Augustin W, Bohnet M. Effect of pH-value on fouling behaviour of heat exchangers. 2018.

Schnöing L, Augustin W, Scholl S. Fouling mitigation in food processes by modification of heat transfer surfaces: a review. Food Bioprod Process. 2020;121:1–19. https://doi.org/10.1016/j.fbp.2020.01.013.

Schoenitz M, Grundemann L, Augustin W, Scholl S. Fouling in microstructured devices: a review. Chem Commun. 2015;51:8213–28. https://doi.org/10.1039/C4CC07849G.

Wray JL, Daniels F. Precipitation of calcite and aragonite. J Am Chem Soc. 1957;79:2031–4.

Wang G, Zhu L, Liu H, Li W. Zinc-graphite composite coating for anti-fouling application. Mater Lett. 2011;65:3095–7. https://doi.org/10.1016/j.matlet.2011.06.096.

Sheikholeslami R, Ng M. Calcium sulfate precipitation in the presence of nondominant calcium carbonate: thermodynamics and kinetics. Ind Eng Chem Res. 2001;40:3570–8.

Dong L, Crittenden BD, Yang M. Fouling characteristics of water–CaSO4 solution under surface crystallization and bulk precipitation. Int J Heat Mass Transf. 2021;66:180.

Ataki A, Kiepfer H, Bart HJ. Investigations on crystallization fouling on PEEK films used as heat transfer surfaces: experimental results. Heat Mass Transf und Stoffuebertragung Heat Mass Transf. 2020;56:1443–52.

Hatch G. Evaluation of scaling tendencies. Mater Prot Perform. 1973;12:49–50.

Hasson D, Zahavi J. Mechanislm of calcium sulfate scale deposition o n heat-transfer surfaces. Ind Eng Chem Fundam. 1970;9:1–10.

Teng KH, Kazi SN, Amiri A, Habali AF, Bakar MA, Chew BT, et al. Calcium carbonate fouling on double-pipe heat exchanger with different heat exchanging surfaces. Powder Technol. 2017;315:216–26. https://doi.org/10.1016/j.powtec.2017.03.057.

Kazi SN, Duffy GG, Chen XD. Fouling and fouling mitigation on heated metal surfaces. Desalination. 2012;288:126–34. https://doi.org/10.1016/j.desal.2011.12.022.

Al-Gailani A, Sanni O, Charpentier TVJ, Crisp R, Bruins JH, Neville A. Inorganic fouling of heat transfer surface from potable water during convective heat transfer. Appl Therm Eng. 2021;184:116271. https://doi.org/10.1016/j.applthermaleng.2020.116271.

Ren L, Cheng Y, Wang Q, Tian X, Yang J, Zhang D. Relationship between corrosion product and fouling growth on mild steel, copper and brass surface. Colloids Surf A Physicochem Eng Asp. 2020;124–502. https://doi.org/10.1016/j.colsurfa.2020.124502

Ren L, Cheng Y, Wang Q, Yang J. Simulation of the relationship between calcium carbonate fouling and corrosion of iron surface. Colloids Surfaces A Physicochem Eng Asp. 2019;66:1238825. https://doi.org/10.1016/j.colsurfa.2019.123882.

Wang J, Wang L, Miao R, Lv Y, Wang X, Meng X, et al. Enhanced gypsum scaling by organic fouling layer on nanofiltration membrane: characteristics and mechanisms. Water Res. 2016;91:203–13. https://doi.org/10.1016/j.watres.2016.01.019.

Cooper A, Suitor JW, Usher JD. Cooling water fouling in plate heat exchangers. Heat Transf Eng. 1980;1:50–5.

Han Z, Xu Z, Wang J. CaSO4 fouling characteristics on the rectangular channel with half-cylinder vortex generators. Appl Therm Eng. 2018;128:1456–63. https://doi.org/10.1016/j.applthermaleng.2017.09.051.

Xu Z, Zhao Y, Wang J, Chang H. Inhibition of calcium carbonate fouling on heat transfer surface using sodium carboxymethyl cellulose. Appl Therm Eng. 2019;148:1074–80. https://doi.org/10.1016/j.applthermaleng.2018.11.088.

Hasan BO, Nathan GJ, Ashman PJ, Craig RA, Kelso RM. The use of turbulence generators to mitigate crystallization fouling under cross flow conditions. Desalination. 2012;288:108–17. https://doi.org/10.1016/j.desal.2011.12.019.

Samadifar M, Toghraie D. Numerical simulation of heat transfer enhancement in a plate-fin heat exchanger using a new type of vortex generators. Appl Therm Eng. 2018;133:671–81. https://doi.org/10.1016/j.applthermaleng.2018.01.062.

Hasan BO, Jwair EA, Craig RA. The effect of heat transfer enhancement on the crystallization fouling in a double pipe heat exchanger. Exp Therm Fluid Sci. 2017;86:272–80. https://doi.org/10.1016/j.expthermflusci.2017.04.015.

Al-Janabi A, Malayeri MR. A criterion for the characterization of modified surfaces during crystallization fouling based on electron donor component of surface energy. Chem Eng Res Des. 2015;100:212–27. https://doi.org/10.1016/j.cherd.2015.05.033.

Großerichter D, Stichlmair J. Crystallization fouling in packed columns. Chem Eng Res Des. 2003;81:68–73.

Zhao L, Tang W, Wang L, Li W, Minkowycz WJ. Heat transfer and fouling characteristics during falling film evaporation in a vertical sintered tube. Int Commun Heat Mass Transf. 2019;109:104388. https://doi.org/10.1016/j.icheatmasstransfer.2019.104388.

Zettler HU, Weiß M, Zhao Q, Müller-Steinhagen H. Influence of surface properties and characteristics on fouling in plate heat exchangers. Heat Transf Eng. 2005;26:3–17.

Feurstein G, Rampf HM. Der Einfluss rechteckiger Rauhigkeiten auf den Waermeuebergang und den Druckabfall in turbulenter Ringspaltstroemung. 1969;2:19–30.

Taylor RP, Hosni MH, Garner JW, Coleman HW. Thermal boundary condition effects on heat transfer in turbulent rough-wall boundary layers. Wärme - und Stoffübertragung. 1992;27:131–40.

Augustin M, Bohnet W. Effect of surface structure and ph-value on fouling behaviour of heat exchangers. Transp Phenom Therm Eng. 1993;2:884–9.

Sheriff N, Gumley P. Heat-transfer and friction properties of surfaces with discrete roughnesses. Int J Heat Mass Transf. 1966;9:1297–320.

Lei C, Peng Z, Day T, Yan X, Bai X, Yuan C. Experimental observation of surface morphology effect on crystallization fouling in plate heat exchangers. Int Commun Heat Mass Transf. 2011;38:25–30. https://doi.org/10.1016/j.icheatmasstransfer.2010.10.006.

Yoon J, Lund DB. Magnetic treatment of milk and surface treatment of plate heat exchangers: effects on milk fouling. J Food Sci. 1994;59:964–9.

McGuire J, Swartzel KR. On the use of water in the measurement of solid surface tension. Surf Interface Anal. 1987;10:430–3.

Herz A, Malayeri MR, Müller-steinhagen H. Fouling of roughened stainless steel surfaces during convective heat transfer to aqueous solutions. Energy Convers Manag. 2008;49:3381–6.

Al-otaibi DA, Hashmi MSJ, Yilbas BS. Fouling resistance of brackish water: comparision of fouling characteristics of coated carbon steel and titanium tubes. Exp Therm Fluid Sci. 2014;55:158–65. https://doi.org/10.1016/j.expthermflusci.2014.03.010.

Abd-Elhady MS, Malayeri MR. Transition of convective heat transfer to subcooled flow boiling due to crystallization fouling. Appl Therm Eng. 2016;92:122–9. https://doi.org/10.1016/j.applthermaleng.2015.09.093.

Rashidi S, Hormozi F, Mohsen M. Fundamental and subphenomena of boiling heat transfer. J Therm Anal Calorim. 2020;6:66. https://doi.org/10.1007/s10973-020-09468-3.

Malayeri MR, Müller-steinhagen H, Bartlett TH. Fouling of tube bundles under pool boiling conditions. Chem Eng Sci. 2005;60:1503–13.

Haghshenasfard M, Yeoh GH, Dahari M, Hooman K. On numerical study of calcium sulphate fouling under sub-cooled flow boiling conditions. Appl Therm Eng. 2015. https://doi.org/10.1016/j.applthermaleng.2015.01.079.

Peyghambarzadeh SM, Vatani A, Jamialahmadi M. Application of asymptotic model for the prediction of fouling rate of calcium sulfate under subcooled fl ow boiling. Appl Therm Eng. 2012;39:105–13. https://doi.org/10.1016/j.applthermaleng.2011.12.042.

Chen JC. Transfer to saturated fluids in convective flow. 1966.

Dash S, Rapoport L, Varanasi KK. Crystallization-induced fouling during boiling: formation mechanisms to mitigation approaches. Langmuir. 2018;34:782–8.

Berce J, Mo M, Golobi I. Infrared thermography observations of crystallization fouling in a plate heat exchanger. 2023. p. 224.

Shaikh K, Kazi SN, Mohd Zubir MN, Wong K, Binti Mohd Yusoff SA, Ahmed Khan W, et al. Mitigation of CaCO3 fouling on heat exchanger surface using green functionalized carbon nanotubes (GFCNT) coating. Therm Sci Eng Prog. 2023;42:101–878.

Cao S, Zou M, Zhao B, Gao H, Wang G. Investigation of corrosion and fouling resistance of Ni–P-nanoparticles composite coating using online monitoring technology. Elsevier Masson SAS; 2023. p. 184.

Müller-Steinhagen H, Malayeri MR, Watkinson AP. Heat exchanger fouling: mitigation and cleaning strategies. Heat Transf Eng. 2011;32:189–96.

Miansari M, Valipour MA, Arasteh H, Toghraie D. Energy and exergy analysis and optimization of helically grooved shell and tube heat exchangers by using Taguchi experimental design. J Therm Anal Calorim. 2020;139:3151–64. https://doi.org/10.1007/s10973-019-08653-3.

Pugh SJ, Hewitt GF, Müller-Steinhagen H. Fouling during the use of fresh water as coolant the development of a user guide. Heat Transf Eng. 2009;30:851–8.

Maddahi MH, Hatamipour MS, Jamialahmadi M. Experimental study of calcium sulfate fouling in a heat exchanger during liquid–solid fluidized bed with cylindrical particles. Int J Therm Sci. 2018;125:11–22. https://doi.org/10.1016/j.ijthermalsci.2017.11.007.

Maddahi MH, Hatamipour MS, Jamialahmadi M. A model for the prediction of thermal resistance of calcium sulfate crystallization fouling in a liquid–solid fluidized bed heat exchanger with cylindrical particles. Int J Therm Sci. 2019;145:106017. https://doi.org/10.1016/j.ijthermalsci.2019.106017.

Pronk P, Infante Ferreira CA, Witkamp GJ. Mitigation of ice crystallization fouling in stationary and circulating liquid–solid fluidized bed heat exchangers. Int J Heat Mass Transf. 2010;53:403–11. https://doi.org/10.1016/j.ijheatmasstransfer.2009.09.016.

Pronk P, Infante Ferreira CA, Witkamp GJ. Prevention of crystallization fouling during eutectic freeze crystallization in fluidized bed heat exchangers. Chem Eng Process Process Intensif. 2008;47:2140–9.

Sousa MFB, Bertran CA. New methodology based on static light scattering measurements for evaluation of inhibitors for in bulk CaCO3 crystallization. J Colloid Interface Sci. 2014;420:57–64. https://doi.org/10.1016/j.jcis.2014.01.001.

Shih W-Y, Albrecht K, Glater J, Cohen Y. A dual-probe approach for evaluation of gypsum crystallization in response to antiscalant treatment. Desalination. 2004;169:213–21.

Müller-Steinhagen H, Malayeri MR, Watkinson AP. Heat exchanger fouling: environmental impacts. Heat Transf Eng. 2009;30:773–6.

Müller-Steinhagen H. Heat transfer fouling: 50 years after the Kern and Seaton model. Heat Transf Eng. 2011;32:1–13.

Moradi A, Toghraie D, Isfahani AHM, Hosseinian A. An experimental study on MWCNT–water nanofluids flow and heat transfer in double-pipe heat exchanger using porous media. J Therm Anal Calorim. 2019;137:1797–807. https://doi.org/10.1007/s10973-019-08076-0.

Shahsavar A, Godini A, Sardari PT, Toghraie D, Salehipour H. Impact of variable fluid properties on forced convection of Fe3O4/CNT/water hybrid nanofluid in a double-pipe mini-channel heat exchanger. J Therm Anal Calorim. 2019;137:1031–43. https://doi.org/10.1007/s10973-018-07997-6.

Kazi SN, Teng KH, Zakaria MS, Sadeghinezhad E, Bakar MA. Study of mineral fouling mitigation on heat exchanger surface. Desalination. 2015;367:248–54. https://doi.org/10.1016/j.desal.2015.04.011.

Teng KH, Amiri A, Kazi SN, Bakar MA, Chew BT. Fouling mitigation on heat exchanger surfaces by EDTA-treated MWCNT-based water nanofluids. J Taiwan Inst Chem Eng. 2016;60:445–52. https://doi.org/10.1016/j.jtice.2015.11.006.

Qian J, Wang J, Yue Z, Wu W. Surface crystallization behavior of calcium carbonate in the presence of SMPs secreted by SRB. J Cryst Growth. 2019;525:125208. https://doi.org/10.1016/j.jcrysgro.2019.125208.

Benecke J, Rozova J, Ernst M. Anti-scale effects of select organic macromolecules on gypsum bulk and surface crystallization during reverse osmosis desalination. Sep Purif Technol. 2018;198:68–78. https://doi.org/10.1016/j.seppur.2016.11.068.

Teng KH, Amiri A, Kazi SN, Bakar MA, Chew BT, Al-Shamma’a A, et al. Retardation of heat exchanger surfaces mineral fouling by water-based diethylenetriamine pentaacetate-treated CNT nanofluids. Appl Therm Eng. 2017;110:495–503. https://doi.org/10.1016/j.applthermaleng.2016.08.181.

Al-Janabi A, Malayeri MR, Müller-Steinhagen H. Experimental fouling investigation with electroless Ni–P coatings. Int J Therm Sci. 2010;49:1063–71.

Yang Q, Ding J, Shen Z. Investigation on fouling behaviors of low-energy surface and fouling fractal characteristics. Chem Eng Sci. 2000;55:797–805.

Yang Q, Liu Y, Gu A, Ding J, Shen Z. Investigation of induction period and morphology of CaCO3 fouling on heated surface. Chem Eng Sci. 2002;57:921–31.

Cheng YH, Zou Y, Cheng L, Liu W. Effect of the microstructure on the anti-fouling property of the electroless Ni–P coating. Mater Lett. 2008;62:4283–5.

Cheng YH, Chen HY, Zhu ZC, Jen TC, Peng YX. Experimental study on the anti-fouling effects of Ni–Cu–P–PTFE deposit surface of heat exchangers. Appl Therm Eng. 2014;68:20–5. https://doi.org/10.1016/j.applthermaleng.2014.04.003.

He ZR, Liu CS, Gao HY, Jie XH, Lian WQ. Experimental study on the anti-fouling effects of EDM machined hierarchical micro/nano structure for heat transfer surface. Appl Therm Eng. 2019;162:66.

Mayer M, Bucko J, Benzinger W, Dittmeyer R, Augustin W, Scholl S. The impact of crystallization fouling on a microscale heat exchanger. Exp Therm Fluid Sci. 2012;40:126–31. https://doi.org/10.1016/j.expthermflusci.2012.02.007.

Vosough A, Peyghambarzadeh SM, Assari MR. Influence of thermal shock on the mitigation of calcium sulfate crystallization fouling under subcooled flow boiling condition. Appl Therm Eng. 2020;164:114434. https://doi.org/10.1016/j.applthermaleng.2019.114434.

Wang J, Liang Y. Anti-fouling effect of axial alternating electromagnetic field on calcium carbonate fouling in U-shaped circulating cooling water heat exchange tube. Int J Heat Mass Transf. 2017;115:774–81. https://doi.org/10.1016/j.ijheatmasstransfer.2017.07.097.

Fan C, Cho YI. Microscopic observation of calcium carbonate particles: validation of an electronic anti-fouling technology. Int Commun Heat Mass Transf. 1997;24:747–56.

Epstein RSTM and N. Optimum cycles for falling rate processes. Depertment chmeical Eng Univ Birtish Colomb. 1981. p. 631–3.

Pogiatzis T, Ishiyama EM, Paterson WR, Vassiliadis VS, Wilson DI. Identifying optimal cleaning cycles for heat exchangers subject to fouling and ageing. Appl Energy. 2012;89:60–6. https://doi.org/10.1016/j.apenergy.2011.01.063.

Diaby AL, Miklavcic SJ, Addai-Mensah J. Optimization of scheduled cleaning of fouled heat exchanger network under ageing using genetic algorithm. Chem Eng Res Des. 2016;113:223–40. https://doi.org/10.1016/j.cherd.2016.07.013.

Di Pretoro A, D’Iglio F, Manenti F. Optimal cleaning cycle scheduling under uncertain conditions: a flexibility analysis on heat exchanger fouling. Processes. 2021;9:1–18.

Al Ismaili R, Lee MW, Wilson DI, Vassiliadis VS. Optimisation of heat exchanger network cleaning schedules: incorporating uncertainty in fouling and cleaning model parameters. Comput Chem Eng. 2019;121:409–21. https://doi.org/10.1016/j.compchemeng.2018.11.009.

Hasson D. Rate of decrease of heat transfer due to scale deposition. Dechema-Monogr. 1962;47:233–52.

Hasson D, Avriel M, Resnick W, Rozenman T, Windreich S. Mechaniism of calcium carbonate heat-transfer surfaces. Ind Eng Chem Res. 1968;7:59–65.

Bansal B, Chen XD, Müller-Steinhagen H. Analysis of “classical” deposition rate law for crystallisation fouling. Chem Eng Process Process Intensif. 2008;47:1201–10.

Nikoo AH, Malayeri MR. Incorporation of surface energy properties into general crystallization fouling model for heat transfer surfaces. Chem Eng Sci. 2020;215:115461. https://doi.org/10.1016/j.ces.2019.115461.

Bohnet M. Fouling of heat transfer surfaces. Chem Eng Technol. 1987;10:113–25.

Segev R, Hasson D, Reegen S. Rigorous modeling of the kinetics of calcium carbonate deposit formation. AIChE J. 2012;58:1222–9.

Yang M, Young A, Niyetkaliyev A, Crittenden B. Modelling fouling induction periods. Int J Therm Sci. 2012;51:175–83. https://doi.org/10.1016/j.ijthermalsci.2011.08.008.

Briançon S, Colson D, Klein JP. Modelling of crystalline layer growth using kinetic data obtained from suspension crystallization. Chem Eng J. 1998;70:55–64.

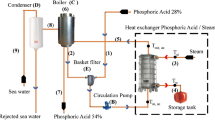

Jamialahmadi M, Müller-Steinhagen H. Heat exchanger fouling and cleaning in the dihydrate process for the production of phosphoric acid. Chem Eng Res Des. 2007;85:245–55.

Esawy M, Malayeri MR. Modeling of CaSO4 crystallization fouling of finned tubes during nucleate pool boiling. Chem Eng Res Des. 2017;118:51–60. https://doi.org/10.1016/j.cherd.2016.11.030.

Babuška I, Silva RS, Actor J. Break-off model for CaCO3 fouling in heat exchangers. Int J Heat Mass Transf. 2018;116:104–14.

Kapustenko PO, Klemeš JJ, Matsegora OI, Arsenyev PY, Arsenyeva OP. Accounting for local thermal and hydraulic parameters of water fouling development in plate heat exchanger. Energy. 2019;174:1049–59.

Souza ARC, Costa ALH. Modeling and simulation of cooling water systems subjected to fouling. Chem Eng Res Des. 2019;141:15–31. https://doi.org/10.1016/j.cherd.2018.09.012.

Bobič M, Gjerek B, Golobič I, Bajsić I. Dynamic behaviour of a plate heat exchanger: influence of temperature disturbances and flow configurations. Int J Heat Mass Transf. 2020;163:66.

Guelpa E, Verda V. Automatic fouling detection in district heating substations: Methodology and tests. Appl Energy. 2020;258:114059. https://doi.org/10.1016/j.apenergy.2019.114059.

Davoudi E, Vaferi B. Applying artificial neural networks for systematic estimation of degree of fouling in heat exchangers. Chem Eng Res Des. 2018;130:138–53. https://doi.org/10.1016/j.cherd.2017.12.017.

Aguel S, Meddeb Z, Jeday MR. Parametric study and modeling of cross-flow heat exchanger fouling in phosphoric acid concentration plant using artificial neural network. J Process Control. 2019;84:133–45.

Sundar S, Rajagopal MC, Zhao H, Kuntumalla G, Meng Y, Chang HC, et al. Fouling modeling and prediction approach for heat exchangers using deep learning. Int J Heat Mass. 2020;159:66.

Benyekhlef A, Mohammedi B, Hassani D, Hanini S. Application of artificial neural network (ANN-MLP) for the prediction of fouling resistance in heat exchanger to MgO-water and CuO-water nanofluids. Water Sci Technol. 2021;84:538–51.

Sholahudin Rohman F, Muhammad D, Sudibyo, Nazri Murat M, Azmi A. Application of feed forward neural network for fouling thickness estimation in low density polyethylene tubular reactor. Mater Today Proc. 2022;63:S95–100. https://doi.org/10.1016/j.matpr.2022.02.037

Brahim F, Augustin W, Bohnet M. Numerical simulation of the fouling on structured heat transfer surfaces (fouling). ECI Conf Heat Exch Fouling Clean Fundam Appl. 2003;RP1:121–9.

Brahim F, Augustin W, Bohnet M. Numerical simulation of the fouling process. Int J Therm Sci. 2003;42:323–34.

Walker P, Sheikholeslami R. Assessment of the effect of velocity and residence time in CaSO4 precipitating flow reaction. Chem Eng Sci. 2003;58:3807–16.

Xiao J, Li Z, Han J, Pan F, Woo MW, Chen XD. A systematic investigation of the fouling induction phenomena with artificial crystal structures and distributions. Chem Eng Sci. 2017;168:137–55. https://doi.org/10.1016/j.ces.2017.04.043.

Yang J. Computational fluid dynamics studies on the induction period of crude oil fouling in a heat exchanger tube. Int J Heat Mass Transf. 2020;159:120129. https://doi.org/10.1016/j.ijheatmasstransfer.2020.120129.

Zhang F, Xiao J, Chen XD. Towards predictive modeling of crystallization fouling: a pseudo-dynamic approach. Food Bioprod Process. 2015;93:188–96. https://doi.org/10.1016/j.fbp.2014.10.017.

Ojaniemi U, Pättikangas T, Jäsberg A, Puhakka E, Koponen A. Computational fluid dynamics simulation of fouling of plate heat exchanger by phosphate calcium. Heat Transf Eng. 2021. https://doi.org/10.1080/01457632.2021.1963551.

Daniali OA, Toghraie D, Eftekhari SA. Thermo-hydraulic and economic optimization of Iranol refinery oil heat exchanger with Copper oxide nanoparticles using MOMBO. Phys A Stat Mech Appl. 2020;540:123010. https://doi.org/10.1016/j.physa.2019.123010.

Caputo AC, Pelagagge M, Salini P. Joint economic optimization of heat exchanger design and maintenance policy. Appl Therm Eng. 2011;31:1381–92.

Ibrahim H. Fouling in heat exchangers. MATLAB A Fundam tool Sci Comput Eng Appl. 2012;3:57–96.

Elwerfalli A, Alsadaie S, Mujtaba IM. Estimation of shutdown schedule to remove fouling layers of heat exchangers using risk-based inspection (RBI). Processes. 2021;66:1–11.

Zhi-ming X, Zhong-bin Z, Shan-rang Y. Costs due to utility fouling in China; 2016.

Awad M. Fouling of heat transfer surfaces; 2021;

ESDU. Heat exchanger fouling in the pre-heat train of a crude oil distillation unit; 2005.

Casanueva-Robles T, Bott TR. The environmental effect of heat exchanger fouling: a case study. In: Proceedings of the 6th international conference heat exchange fouling cleaning, challenges opportunities RP2; 2005. p. 5–10.

Acknowledgements

This study is supported financially under the Fundamental Research Grant Scheme awarded by the Ministry of Higher Education Malaysia with Grant Number: FRGS/1/2019/TK03/UM/02/12 (FP143-2019A). The authors also gratefully acknowledge the support from Grants, RMF0400-13-2021, ST049-2022, RK001-2022, Centre of Advanced Manufacturing and Material Processing (AMMP), Centre for Energy Sciences(CES), Centre of Advanced Materials (CAM), Department of Mechanical Engineering, Universiti Malaya, and BUITEMS, Pakistan to conduct this research work.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shaikh, K., Newaz, K.M.S., Zubir, M.N.M. et al. A review of recent advancements in the crystallization fouling of heat exchangers. J Therm Anal Calorim 148, 12369–12392 (2023). https://doi.org/10.1007/s10973-023-12544-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12544-z