Abstract

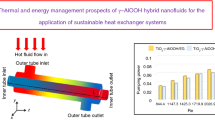

The application of nanofluids to increase the heat transfer rate in heat exchangers of a proposed dual-loop RC–ORCheat recovery system (RC with water and ORC with R141b working fluids) is investigated here. The effects of adding nanoparticles into working fluids of a heat recovery system with two RC and ORC loops and its performance, has not been studied so far. Appropriate single-phase/two-phase heat transfer coefficients have been used for nanofluids in the system modeling by extracting their properties from available experimental data. Performance evaluation criterion (PEC) was also applied to assess and compare the performance of nanofluids in the proposed system. Optimization of the proposed system with exergy efficiency and payback period as objective functions for various nanofluids (working fluids mixed with four nanoparticles Al2O3, CuO, Cu, TiO2) with various volume fraction (0.5, 1, and 2%) which satisfied PEC > 1 provided a Pareto front. The selected optimum point from Pareto front by TOPSIS method showed that the proposed dual loop RC–ORC system with water/Cu nanofluid (with volume percent of 2% for the RC loop) and 141b/Cu nanofluid (with a volume percent of 0.5% for the ORC loop) had the most suitable performance (higher thermal and exergy efficiencies and lower payback period). Under these conditions, the thermal efficiency, the exergy efficiency, the turbine power output and the annual net profit of the proposed RC–ORC system increased by (4.4%), (17.2%), (15.4%) and (15.6%) respectively.

Similar content being viewed by others

Data availability

Data and codes may be available upon reasonable requests.

Abbreviations

- \(A\) :

-

Heat transfer surface area (m2)

- \(AP\) :

-

Yearly profit ($ year−1)

- \(C_{{{\text{CO}}2}}\) :

-

Penalty cost of CO2 per kg ($ kg−1)

- \(C_{{{\text{elec}},{\text{B}}}}\) :

-

Price of electricity consumption ($ kWh−1)

- \(C_{{{\text{elec}},{\text{s}}}}\) :

-

Price of electricity selling ($ kWh−1)

- \(C_{{\text{f}}}\) :

-

Cost of Fuel (S m−3)

- \(C_{{{\text{in}},{\text{an}}}}\) :

-

Annual investment cost ($ year−1)

- \(C_{{{\text{inv}}}}\) :

-

Investment cost ($)

- \(C_{{\text{m}}}\) :

-

Production of CO2 per Kw h (kg kWh−1)

- \(C_{{\text{P}}}\) :

-

Specific heat capacity (kJ kg−1 K−−1)

- \(C_{{{\text{Penalty}}}}\) :

-

CO2 penalty cost ($)

- \(CRF\) :

-

Factor of capital recovery

- \(d\) :

-

Diameter of tube (m)

- \(\dot{E}\) :

-

Rate of exergy (kW)

- \(F\) :

-

Correction factor for logarithmic mean temperature difference

- \(f_{{\text{g}}}\) :

-

Friction factor

- \(G\) :

-

Mass velocity (kg.s−1 m−2)

- \(H\) :

-

Annual working hour (h)

- \(h\) :

-

Specific enthalpy (kJ kg−1)

- \(I_{{{\text{e}},{\text{s}}}}\) :

-

Electricity selling income ($)

- \(i\) :

-

Rate of Interest (%)

- \(K_{{\text{m}}}\) :

-

Tube wall thermal conductivity (W m−1 K−1)

- \(LHV\) :

-

Lower heating value (Kcal m−3)

- \(\dot{m}\) :

-

Mass flow rate (kg s−1)

- \(Nu\) :

-

Nusselt number

- \(n\) :

-

Lifetime of system (year)

- \(P\) :

-

Pressure (bar)

- \(PBP\) :

-

Payback period (year)

- \(PL\) :

-

Partial load (%)

- \(Pr\) :

-

Prandtl number

- \(Q\) :

-

Volumetric flow rate (m3 s−1)

- \(\dot{Q}\) :

-

Heat transfer rate (kW)

- \(Re\) :

-

Reynolds number

- \(s\) :

-

Specific entropy (kJ kg−1)

- \(T\) :

-

Temperature (°C)

- \(U\) :

-

Overall heat transfer coefficient (Wm−2 K−1)

- \({\text{V}}\) :

-

Velocity of water (m s−1)

- \(\dot{W}\) :

-

Produced/consumed rate (kW) of work

- \(x\) :

-

Quality of steam

- \({\text{APTD}}\) :

-

Approach point temperature difference

- \({\text{amb}}\) :

-

Ambient

- \({\text{atm}}\) :

-

Atmosphere

- bf:

-

Base fluid

- \({\text{Cond}}\) :

-

Condenser

- \({\text{CHP}}\) :

-

Combined heat and power

- \({\text{Des}}\) :

-

Exergy destruction

- \({\text{DOS}}\) :

-

Degree of superheat

- \({\text{Eva}}\) :

-

Evaporator

- \({\text{exp}}\) :

-

Expander

- \({\text{f}}\) :

-

Fuel

- \({\text{GE}}\) :

-

Gas engine

- \({\text{g}}\) :

-

Gas

- \({\text{HRSG}}\) :

-

Heat recovery steam generator

- \({\text{i}}\) :

-

Internal

- is:

-

Isentropic

- \({\text{JCW}}\) :

-

Jacket cooling water

- \({\text{ma}}\) :

-

Maintenance

- \({\text{NTU}}\) :

-

Number of transfer unit

- np:

-

Nanoparticle

- \({\text{OP}}\) :

-

Operational

- \({\text{ORC}}\) :

-

Organic Rankine cycle

- \({\text{o}}\) :

-

Outer

- \({\text{RC}}\) :

-

Rankine cycle

- \({\text{ST}}\) :

-

Steam turbine

- \({\text{SV}}\) :

-

Salvage value

- α:

-

Heat transfer coefficient (Wm−2 K−1)

- \({\upeta }_{{{\text{thermal}}}}\) :

-

Thermal efficiency (%)

- \({\upeta }_{{{\text{ex}}}}\) :

-

Exergy efficiency (%)

- \(\varphi\) :

-

Volumetric fraction of nano particle

- \(\gamma \left( {i,n} \right)\) :

-

Sinking fund factor

- \(\Delta p_{{\text{g}}}\) :

-

Gas side pressure drop (kPa)

- \({\uprho }\) :

-

Density (kg m−3)

- \({\upmu }\) :

-

Dynamic viscosity (Pa s)

- \(\omega\) :

-

Mass coefficient of nano particle

- \(s\) :

-

Isentropic process

- \(st\) :

-

Steam

- \(t\) :

-

Turbine

- \(Wa\) :

-

Water

- \(Wf\) :

-

Working fluid

References

Prajapati P, Patel VK. Thermo-economic optimization of a nanofluid based organic Rankine cycle: a multi-objective study and analysis. Therm Sci Eng Prog. 2019. https://doi.org/10.1016/j.tsep.2019.100381.

Kosmadakis G, Neofytou P. Investigating the performance and cost effects of nanorefrigerants in a low-temperature ORC unit for waste heat recovery. Energy. 2020. https://doi.org/10.1016/j.energy.2020.117966.

Mondejar ME, Andreasen JG, Regidor M, Riva S, Kontogeorgis G, Persico G, Haglind F. Prospects of the use of nanofluids as working fluids for organic Rankine cycle power systems. Energy Procedia. 2017;129:160–7.

McGrail BP, Thallapally PK, Blanchard J, Nune SK, Jenks JJ, Dang LX. Metal-organic heat carrier nanofluids. Nano Energy. 2013;2:845–55.

Cavazzini G, Bari S, McGrail P, Benedetti V, Pavesi G, Ardizzon G. Contribution of metal-organic-heat carrier nanoparticles in a R245fa low grade heat recovery organic Rankine cycle. Energy Convers Manag. 2019. https://doi.org/10.1016/j.enconman.2019.111960.

Said Z, Sharma P, Tiwari AK, Le VV, Huang Z, Bui V, Hoang AT. Application of novel framework based on ensemble boosted regression trees and Gaussian process regression in modelling thermal performance of small-scale organic Rankine cycle (ORC) using hybrid nanofluid. J Clean Prod. 2022. https://doi.org/10.1016/j.jclepro.2022.132194.

Li Y, Xu SZ. Thermodynamic analysis of subcritical/transcritical ORCs with metal–organic heat carriers for efficient power generation from low-grade thermal energy. Energy. 2022. https://doi.org/10.1016/j.energy.2022.124519.

Gupta R, Tiwari AK, Said Z. Performance evaluation of small scale solar organic Rankine cycle using MWCNT+R141b nanorefrigerant. Energy Convers Manag. 2022. https://doi.org/10.1016/j.enconman.2022.115631.

Feng Y, Shi R, Liu Y, Wang X, Wu X, Huang X, He Z, Hung TC. Flow and heat transfer characteristics of nano-organic working fluid during evaporation for organic Rankine cycle. Appl Therm Eng. 2023. https://doi.org/10.1016/j.applthermaleng.2022.119310.

Ju Y, Abdalla AN, Wang S, Hai T, Wei H, Wang M. Exergetic evaluation of the effect of nanofluid utilization for performance enhancement of a solar driven hydrogen production plant. Int J Hydrog Energy. 2023. https://doi.org/10.1016/j.ijhydene.2023.01.204.

Jiang F, Zhu J, Xin G. Experimental investigation on Al2O3-R123 nanorefrigerant heat transfer performances in evaporator based on organic Rankine cycle. Int J Heat Mass Transf. 2018. https://doi.org/10.1016/j.ijheatmasstransfer.2018.07.061.

Saadatfar B, Fakhrai R, Fransson T. Conceptual modeling of nano fluid ORC for solar thermal polygeneration. Energy Procedia. 2014;57:2696–705.

Huang H, Zhu J, Yan B. Comparison of the performance of two different dual-loop organic Rankine cycles (DORC) with nanofluid for engine waste heat recovery. Energy Convers Manag. 2016. https://doi.org/10.1016/j.enconman.2016.07.081.

Alashkar A, Gadalla M. Thermo-economic analysis of an integrated solar power generation system using nanofluids. Appl Energy. 2017. https://doi.org/10.1016/j.apenergy.2017.01.084.

Abid M, Ratlamwala TAH, Atikol U. Solar assisted multi-generation system using nanofluids: A comparative analysis. Int J Hydrog Energy. 2017. https://doi.org/10.1016/j.ijhydene.2017.05.178.

Rahbar K, Riasi A, Sangjoeei B, Razmjoo N. Heat recovery of nano-fluid based concentrating Photovoltaic Thermal (CPV/T) Collector with Organic Rankine Cycle. Energy Convers Manage. 2018. https://doi.org/10.1016/j.enconman.2018.10.066.

Boyaghchi F, Chavoshi M. Multi-criteria optimization of a micro solar-geothermal CCHP system applying water/CuO nanofluid based on exergy, exergoeconomic and exergoenvironmental concepts. Appl Therm Eng. 2017. https://doi.org/10.1016/j.applthermaleng.2016.10.139.

Loni R, Askari Asli-Ardeh E, Ghobadian B, Najafi G, Bellos E. Effects of size and volume fraction of alumina nanoparticles on the performance of a solar organic Rankine cycle. Energy Convers Manage. 2019. https://doi.org/10.1016/j.enconman.2018.12.079.

Peng Q, Jia L, Dang C, Zhang X, Huang Q. Experimental investigation on flow condensation of R141b with CuO nanoparticles in a vertical circular tube. Appl Therm Eng. 2017. https://doi.org/10.1016/j.applthermaleng.2017.10.108.

Sun B, Yang D. Flow boiling heat transfer characteristics of nano-refrigerants in a horizontal tube. Int J Hydrogen Energy. 2013. https://doi.org/10.1016/j.ijrefrig.2013.08.020.

Eid EI, Khalaf-Allah RA, Tolan M. Enhancement of pool boiling characteristics by an addition of nano Aluminum oxide to R-141b over a rough horizontal steel circular heater. Int J Refrig. 2018. https://doi.org/10.1016/j.ijrefrig.2018.11.006.

Naphon P, Thongjing C. Pool boiling heat transfer characteristics of refrigerant-nanoparticle mixtures. Int Commun Heat Mass Transfer. 2014. https://doi.org/10.1016/j.icheatmasstransfer.2014.01.014.

Karimzadehkhouei M, Shojaeian M, Sendur K, Mengüç MP, Kosar A. The effect of nanoparticle type and nanoparticle mass fraction on heat transfer enhancement in pool boiling. Int J Heat Mass Transf. 2017. https://doi.org/10.1016/j.ijheatmasstransfer.2017.01.116.

Celen A, Çebi A, Aktas M, Mahian O, Dalkilic AS, Wongwises S. A review of nanorefrigerants: Flow characteristics and Applications. Int J Refrig. 2014. https://doi.org/10.1016/j.ijrefrig.2014.05.009.

Ali HM, Generous MM, Ahmad F, Irfan M. Experimental investigation of nucleate pool boiling heat transfer enhancement of TiO2-Water based nanofluids. Appl Therm Eng. 2016. https://doi.org/10.1016/j.applthermaleng.2016.11.127.

Kim S, Tserengombo B, Choi SH, Noh J, Huh S, Choi B, Chung H, Kim J, Jeong H. Experimental Investigation of Heat Transfer Coefficient with Al2O3 Nanofluid in Small Diameter Tubes. Appl Therm Eng. 2018. https://doi.org/10.1016/j.applthermaleng.2018.10.001.

Moreira TA, Nascimento F, Ribatski G. An investigation of the effect of nanoparticle composition and dimension on the heat transfer coefficient during flow boiling of aqueous nanofluids in small diameter channels. Exp Thermal Fluid Sci. 2017. https://doi.org/10.1016/j.expthermflusci.2017.07.020.

Zarringhalam M, Karimipour A, Toghraie D. Experimental study of the effect of solid volume fraction and Reynolds number on heat transfer coefficient and pressure drop of CuO-Water nanofluid. Exp Thermal Fluid Sci. 2016. https://doi.org/10.1016/j.expthermflusci.2016.03.026.

Dadhich M, Prajapati O, Sharma V. Investigation of boiling heat transfer of titania nanofluid flowing through horizontal tube and optimization of results utilizing the desirability function approach. Powder Technol. 2020. https://doi.org/10.1016/j.powtec.2020.09.077.

Cuenca RM, Mondragón R, Hernández L, Segarra C, Jarque JC, Hibiki T, Juliá JE. Forced-convective heat-transfer coefficient and pressure drop of water-based nanofluids in a horizontal pipe. Appl Therm Eng. 2015. https://doi.org/10.1016/j.applthermaleng.2015.11.050.

Ansarpour M, Danesh E, Mofarahi M. Investigation the effect of various factors in a convective heat transfer performance by ionic liquid, ethylene glycol, and water as the base fluids for Al2O3 nanofluid in a horizontal tube: a numerical study. Int Commun Heat Mass Trans. 2020. https://doi.org/10.1016/j.icheatmasstransfer.2020.104556.

Du R, Jiang D, Wang Y, Shah KW. An experimental investigation of CuO/water nanofluid heat transfer in geothermal heat exchanger. Energy Build. 2020. https://doi.org/10.1016/j.enbuild.2020.110402.

Sanaye S, Ghafari A. Thermo-economic multi-objective optimization of an innovative Rankine–organic Rankine dual-loop system integrated with a gas engine for higher energy/exergy efciency and lower payback period. J Therm Anal Calorim. 2021. https://doi.org/10.1007/s10973-021-10753-y.

Bellos E, Tzivanidis C. A review of concentrating solar thermal collectors with and without nanofluids. J Therm Anal Calorim. 2018. https://doi.org/10.1007/s10973-018-7183-1.

Abdollahpour A, Ghasempour R, Kasaeian A, Ahmadi MH. Exergoeconomic analysis and optimization of a transcritical CO2 power cycle driven by solar energy based on nanofluid with liquefied natural gas as its heat sink. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08375-6.

Molana M, Wang H. A critical review on numerical study of nanorefrigerant heat transfer enhancement. Powder Technol. 2020. https://doi.org/10.1016/j.powtec.2020.04.044.

Baniamerian Z. Analytical Modeling of Boiling Nanofluids. J Thermophys Heat Transfer. 2017. https://doi.org/10.2514/1.T4910.

Sudarmadji S. Performance Evaluation Criterion of Nanofluid. Microfluid Nanofluid. 2018. https://doi.org/10.5772/intechopen.74610.

Bellos E, Tzivanidis C. Parametric analysis and optimization of an Organic Rankine Cycle with nanofluid based solar parabolic trough collectors. Renewable Energy. 2017. https://doi.org/10.1016/j.renene.2017.06.055.

Funding

No funding was received to assist with the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

SS: Supervision, conceptualization, methodology, translation and reviewing, editing. AG: investigation, methodology, software, software validation, data curation, original draft preparation.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare no potential conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A: governing equations for modeling the dual loop RC–ORC system

Modeling (energy)

Governing energy equations for pumps, turbines and heat exchanger of the integrated RC-ORC-GE system are listed in Table 12.

Modeling (exergy)

Exergy is defined as the maximum work attainable during a process from one specific state to the dead state as following:

The equipment exergy destruction rates in the above Rankine–Organic Rankine system are also listed in Table 13:

The exergy efficiency and the total exergy destruction rate of the system are expressed by Eqs. (20)–(22) [33]:

Modeling (economic)

The following sections cover the estimation of annual income, annual net profit, payback period, the operational cost and the equipment investment cost:

Investment cost

The cost functions with their constant coefficients for equipment investment cost are presented in Tables 14 and 15 respectively.

The annual investment cost are estimated by the Eq. (24):

The yearly maintenance cost was assumed to be 6% of the capital cost.

Operating cost

Electricity consumption of fans and pumps which are estimated by Eq. (26) are the system operating cost.

Income and salvage value

Selling electricity income and the salvage value are obtained by the following equations respectively:

Payback period

Payback period is computed by Eq. (29):

Annual profit (AP)

Annual profit is defined as the difference between income and all costs of the system as is expressed in Eq. (30):

Heat transfer coefficients

The single/two-phase flow heat transfer coefficients are listed in Tables 16 and 17.

Chen correlation is used for two-phase forced convective and nucleate boiling processes. For two-phase flow in inner pipe of condenser, Dobson and Chato correlation is used for Reynolds number lower than 35,000 while Boyko and Kruzhilin correlation is utilized for higher Reynolds number.

The allowed variations of decision variables and constrains in optimization

Decision variables with their variation range for the studied system are presented in Table 18.

The following constraints are also applied in the system optimization:

-

(1)

The gas engine exhaust temperature must be higher than its dew point temperature (to avoid stack corrosion)

-

(2)

To prevent the back pressure phenomenon, the pressure drop in the gas side of HRSG should be lower than 0.045 bar.

-

(3)

The system power loss which is computed from Eq. (30), should be lower than a determined value \(\left( { \prec 3\% } \right)\):

$$ \Delta W\left( {kW} \right) = \dot{m}_{\text{g}} c_{\text{P,g}} \eta_{\text{GE}} T_{\text{GE}} \left( {\left( {\frac{{P_{\text{atm}} }}{{P_{\text{GE}} }}} \right)^{{{\raise0.7ex\hbox{${\gamma - 1}$} \!\mathord{\left/ {\vphantom {{\gamma - 1} \gamma }}\right.\kern-0pt} \!\lower0.7ex\hbox{$\gamma $}}}} - \left( {\frac{{P_{\text{atm}} + \Delta P}}{{P_{\text{GE}} }}} \right)^{{{\raise0.7ex\hbox{${\gamma - 1}$} \!\mathord{\left/ {\vphantom {{\gamma - 1} \gamma }}\right.\kern-0pt} \!\lower0.7ex\hbox{$\gamma $}}}} } \right) $$(31)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sanaye, S., Ghaffari, A. Performance improvement and optimizing an innovative dual-loop RC–ORC heat recovery system with nano-working fluids. J Therm Anal Calorim 148, 10991–11012 (2023). https://doi.org/10.1007/s10973-023-12450-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12450-4